Tape replacing device of belt type conveyer

A technology of belt conveyor and traction device, which is applied in the direction of conveyor, transportation and packaging, and sending objects, etc., which can solve the problems of complex belt replacement work, long replacement cycle, and large manpower and material resources, so as to improve production efficiency and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Referring to the accompanying drawings, each component of the device is an independent unit, which can be operated in conjunction at the same time, and can also be used as a stand-alone unit in different occasions. Each component can choose a suitable installation position according to the environmental conditions of the tape machine site. Its main structure is:

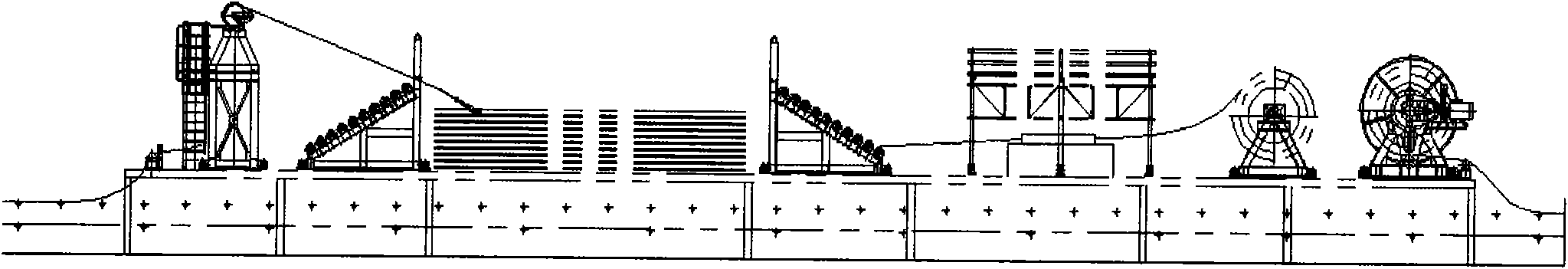

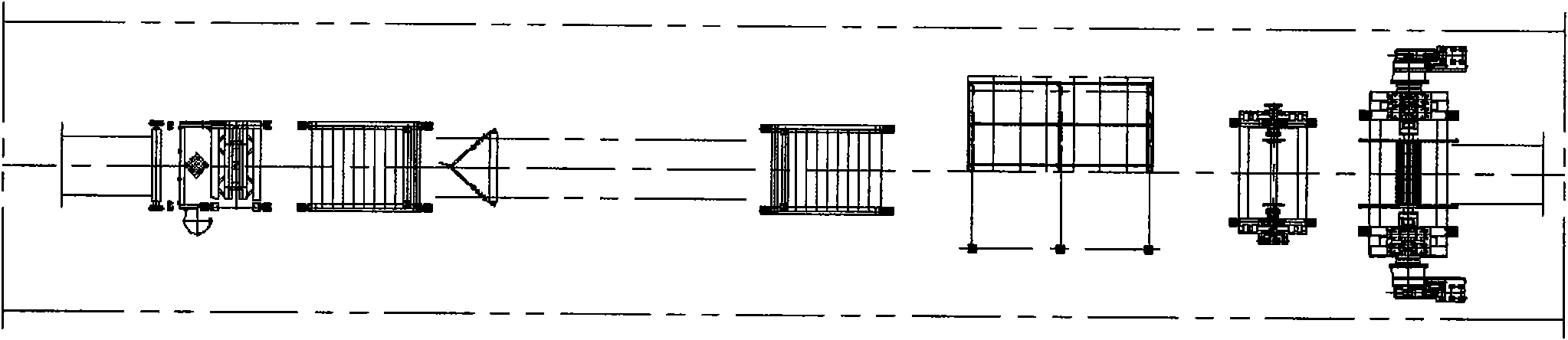

[0023] A belt changing device for a belt conveyor. The whole device is composed of four major components: a tape winding device, a tape unwinding device, a tape storage device, and a traction device. The entire device follows the order of the tape winding device, the tape unwinding device, the tape storage device, and the traction device layout.

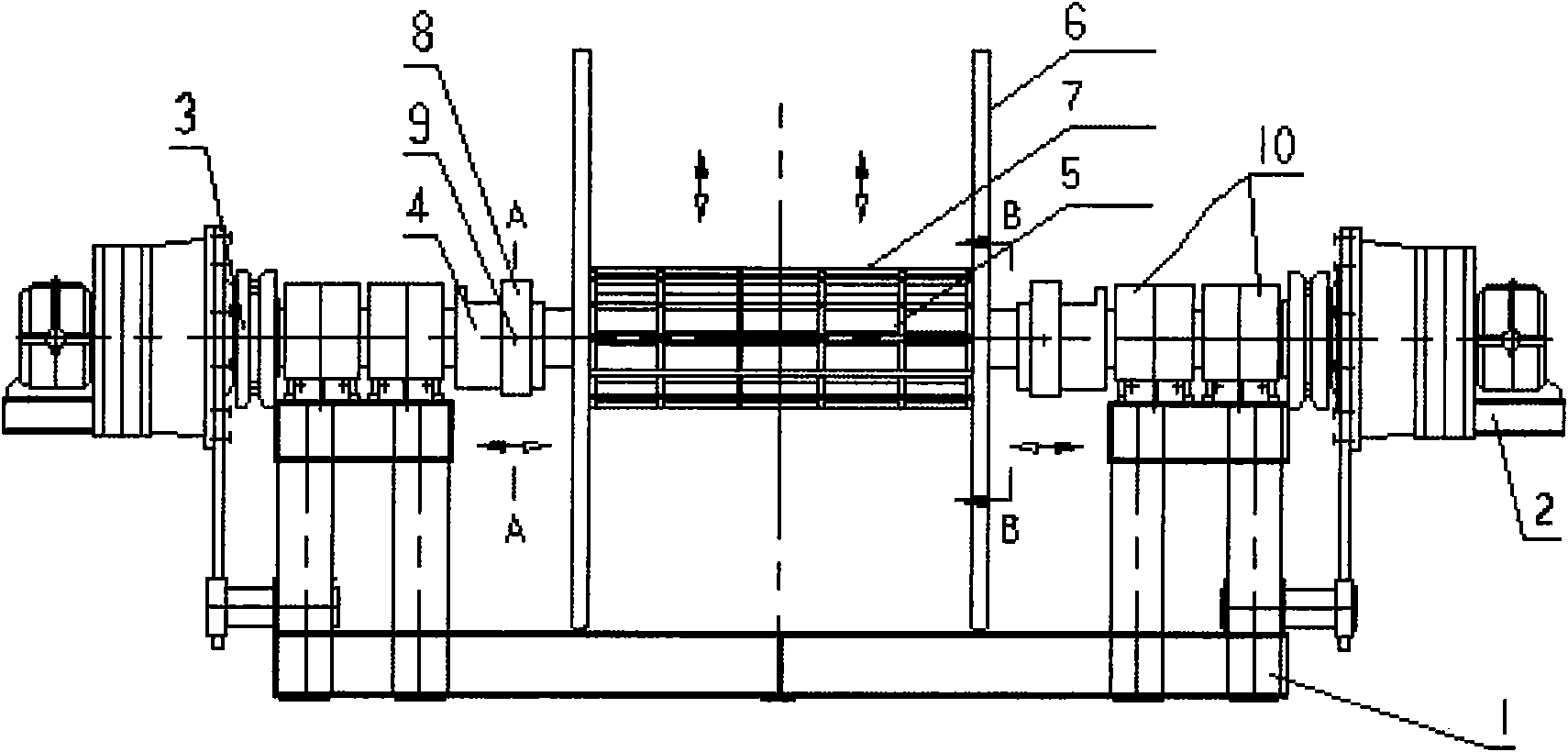

[0024] The tape winding device is composed of the first bracket 1, the driving device 2, the locking disc 3, the transmission shaft 4, the first square shaft 5, the retaining ring 6, the belt core 7, the snap ring 8, the positioning pin 9, and the double bearing sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com