Inertia force balance method of high speed punching machine crank connecting rod sliding block mechanism

A technology of crank connecting rod and high-speed punch press, which is applied in inertia force compensation, special data processing applications, instruments, etc., can solve the problems that cannot be used in production practice, does not solve the reasonable vibration isolation method and the adjustment method of die height, and affects the high-speed punch industry. development and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

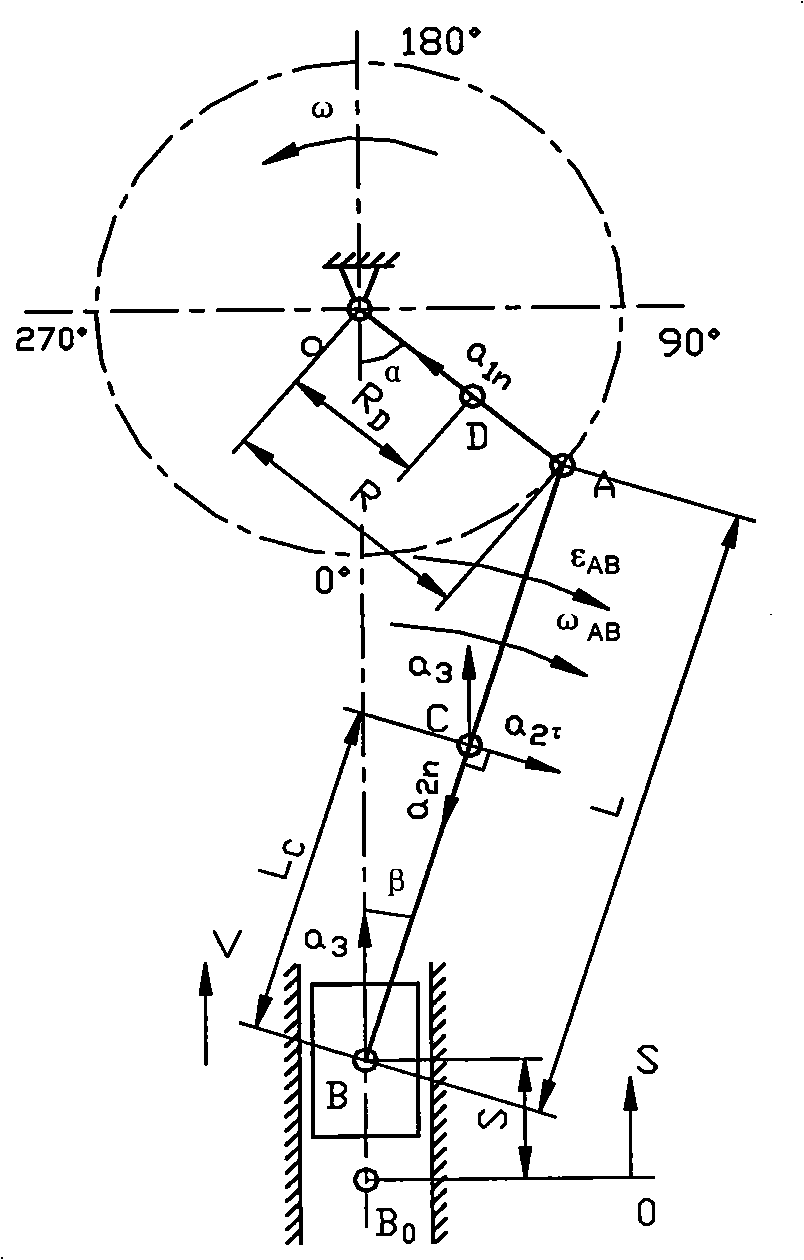

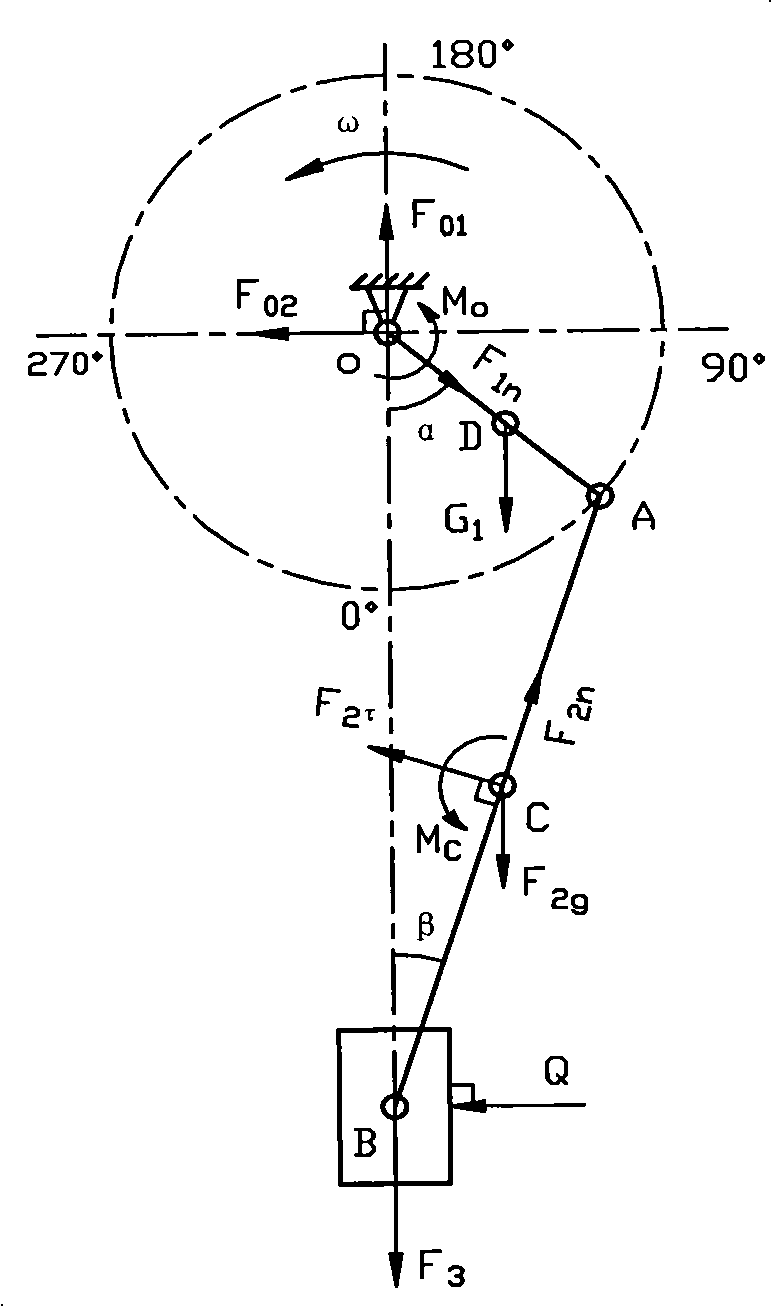

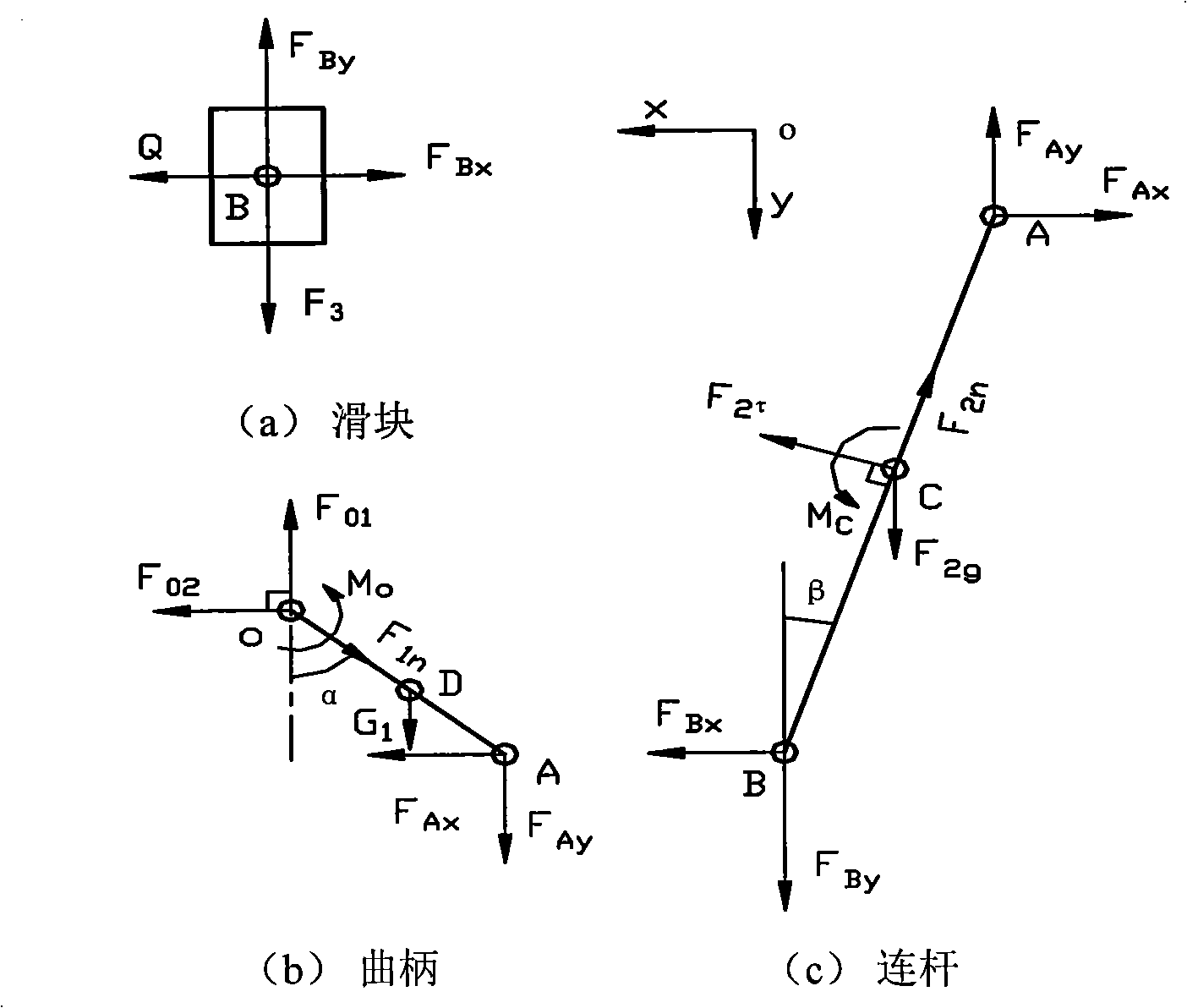

[0074] 1. On the basis of the motion analysis of the centering upright crank connecting rod slider mechanism with the crank rotation angular velocity as a constant, the accurate and simplified expressions of the displacement, velocity and acceleration of the slider of the mechanism and the swing angular velocity of the connecting rod are established ; The expressions of the centripetal acceleration of the crank mass center, the translation of the connecting rod mass center, centripetal and tangential accelerations and the angular acceleration of the connecting rod swing are obtained further. Such as figure 1 As shown, points C and D in the figure are the centroids of connecting rod AB and crank OA respectively; and there are OA=R, OD=R D , AB=L, AC=L A ,BC=L C , crank mass m 1 , slider mass m 2 , connecting rod mass m 3 . The connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com