F+P+B type low-yield-ratio and high-strength medium steel plate and production method thereof

A technology with low yield ratio and production method, applied in the field of high-strength medium and heavy plate steel, can solve the problems of increased production cycle, high alloy cost and high process cost, and achieve short production cycle, low alloy cost and social resource saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

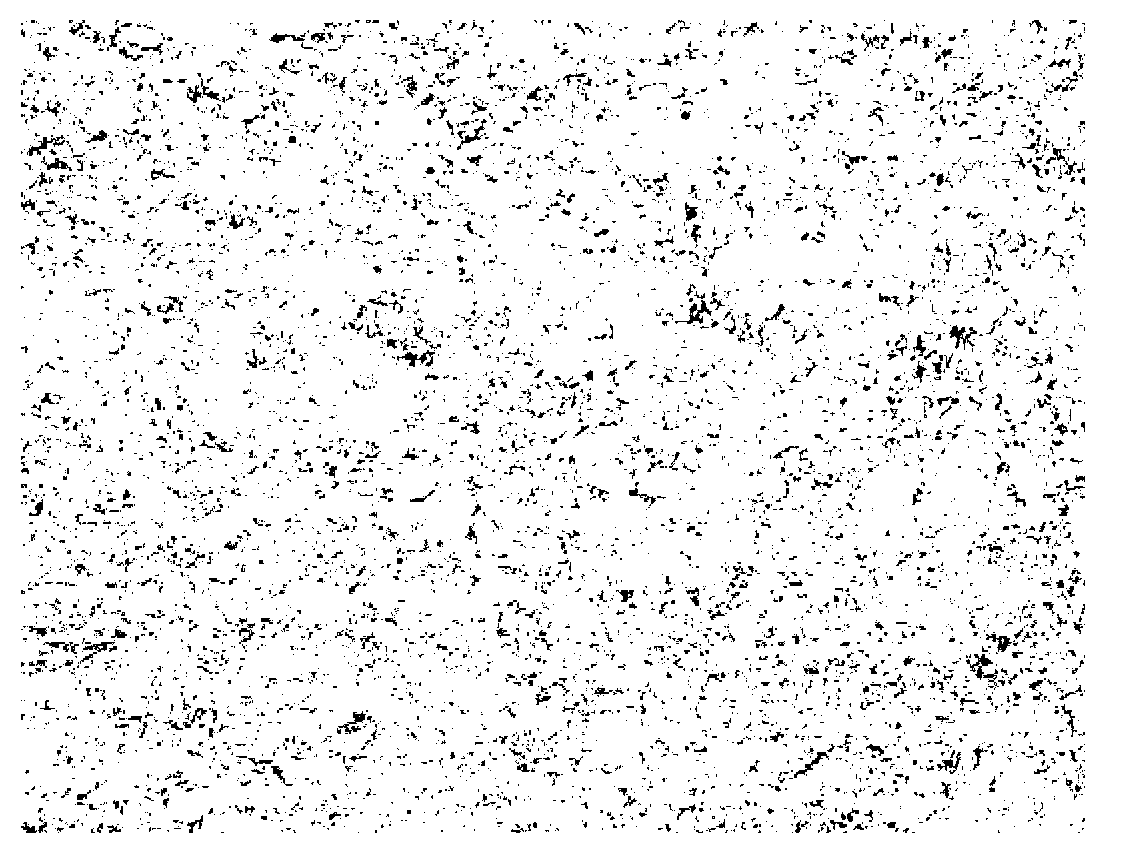

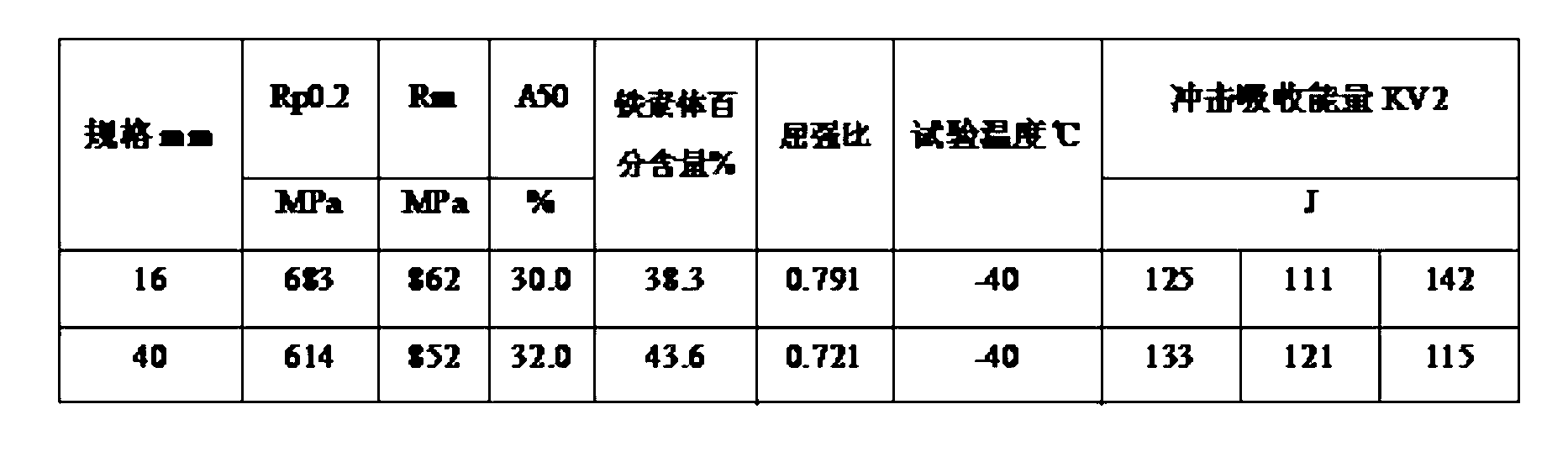

Embodiment 1

[0032] This implementation is the production process of F+P+B type low-yield ratio high-strength steel plate with a specification of 16mm, and its composition weight percentage is C: 0.09%, Si: 0.3%, Mn: 1.95%, P: 0.009%, S: 0.006%, Al: 0.03%, Nb: 0.055%, Ti: 0.015%, V: 0.06%, Cr: 0.15%, B: 0.0015%, and the balance is Fe and unavoidable inclusions.

[0033] The production process is carried out according to the following procedures:

[0034] (1) Smelting: Smelting in a 50kg vacuum induction furnace and casting into ingots of 120mm*120mm*300mm.

[0035] (2) Controlled rolling, waiting temperature and ultra-fast controlled cooling parameters:

[0036] Heating temperature: The billet heating temperature in this test is set at 1180°C, and the heating time is 4 hours.

[0037]Controlled rolling: Two-stage controlled rolling is adopted. The starting rolling temperature in the rough rolling stage is 1160°C, and the pass reduction rate is 25%; the thickness of the rolled piece to b...

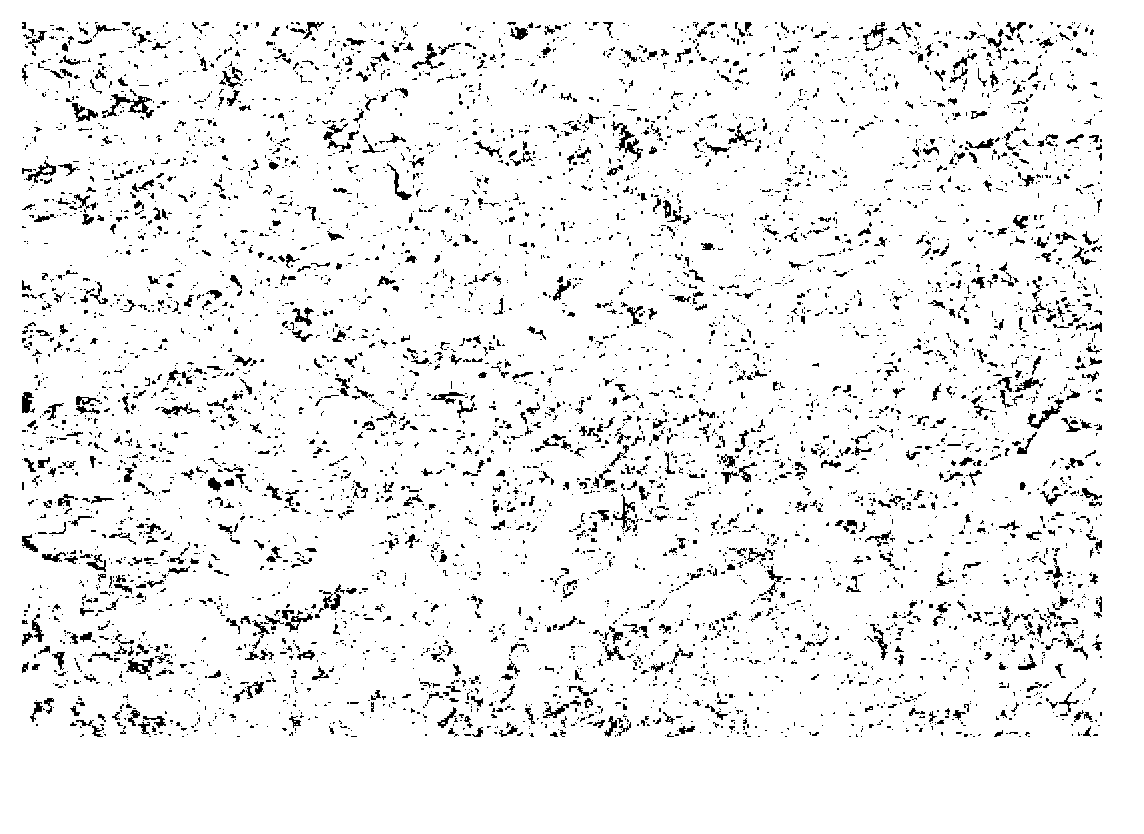

Embodiment 2

[0040] This example is a production process of F+P+B type low-yield-ratio high-strength steel plate with a specification of 40mm, and its composition weight percentage is C: 0.10%, Si: 0.28%, Mn: 1.97%, P: 0.01%, S : 0.006%, Al: 0.03%, Nb: 0.06%, Ti: 0.014%, V: 0.055%, Cr: 0.16%, B: 0.0016%, and the balance is Fe and unavoidable inclusions.

[0041] The production process is carried out according to the following procedures:

[0042] (1) Smelting: Smelting in a 50kg vacuum induction furnace and casting into ingots of 120mm*120mm*300mm.

[0043] (2) Controlled rolling, waiting temperature and ultra-fast controlled cooling parameters:

[0044] Heating temperature: The billet heating temperature in this test is set at 1180°C, and the heating time is 4 hours.

[0045] Controlled rolling: Two-stage controlled rolling is adopted. The starting rolling temperature in the rough rolling stage is 1160°C, and the pass reduction rate is 20%; the thickness to be warmed in the middle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com