High-intensity and high-temperature-resistant anti-erosion oil well cement and preparation method thereof

A technology of oil well cement and high temperature resistance, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of changes in the physical and chemical properties of cement slurry, bad bottom hole environment, affecting cementing quality, etc., and achieves low alkali content control. , Reduce the mixing process, the effect of anti-chemical erosion effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

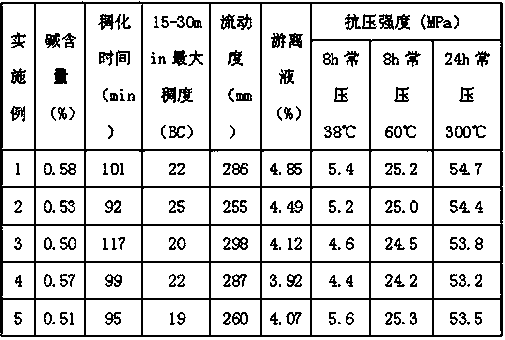

[0021] Example 1: A high-strength, high-temperature-resistant, anti-erosion oil well cement. By mass percentage: G-grade high-resistance oil well clinker 50%, aluminophosphate cement clinker 10%, silica sand 30%, phosphogypsum 4.5%, silica fume 5.5%, fluid loss reducer 0.1%, retarder 0.3 %, mixed and ground to produce high-strength, high-temperature-resistant and anti-erosion oil well cement, wherein the retarder is made of the following raw materials in mass percentage: industrial starch 48%, industrial sugar 20%, microsilica fume 10%, phosphogypsum It is obtained by mixing 15% powder, 6% borax and 1% white carbon black and grinding them until the specific surface area is 350-400㎡ / kg. The cement physical properties of this embodiment are as shown in Table 1, Example 1.

Embodiment 2

[0022] Embodiment 2: A high-strength, high-temperature-resistant, anti-erosion oil well cement. By mass percentage: G-grade high-resistance oil well clinker 55%, aluminophosphate cement clinker 12%, silica sand 25%, phosphogypsum 4.5%, silica fume 3.5%, fluid loss reducer 0.12%, retarder 0.35% %, after mixing and grinding, high-strength, high-temperature-resistant and anti-erosion oil well cement can be prepared, wherein the retarder is made of the following raw materials by mass percentage: microsilica fume 13%, phosphogypsum powder 11%, industrial starch 35%, industrial starch It is obtained by mixing 30% granulated sugar, 7% borax, and 4% white carbon black and grinding them until the specific surface area is 350-400㎡ / kg. The cement physical properties of this embodiment are shown in Table 1, Example 2.

Embodiment 3

[0023] Embodiment 3: A high-strength, high-temperature-resistant, corrosion-resistant oil well cement. By mass percentage: G-grade high-resistance oil well clinker 60%, aluminophosphate cement clinker 10%, silica sand 20%, phosphogypsum 5.0%, silica fume 5.0%, fluid loss reducer 0.12%, retarder 0.5% %, after mixing and grinding, high-strength, high-temperature-resistant and anti-erosion oil well cement can be obtained, wherein the retarder is made of the following raw materials in mass percentage: microsilica fume 15%, phosphogypsum powder 10%, industrial starch 30%, industrial starch It is obtained by mixing 35% granulated sugar, 7% borax, and 3% white carbon black and grinding them until the specific surface area is 350-400㎡ / kg. The cement physical properties of this embodiment are shown in Table 1, Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com