Heat insulation anchoring structure for water conservancy dam polyurea anti-seepage coatings and construction method

A technology of anti-seepage coating and anchoring structure, which is applied in the fields of moisturizing, heat preservation and anchorage structure and construction, water conservancy concrete dam seepage prevention and heat preservation, and can solve the problems of foam ice damage, foam cracking, bulging, and peeling, etc., with little impact , protection of thermal insulation effect, the effect of small thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

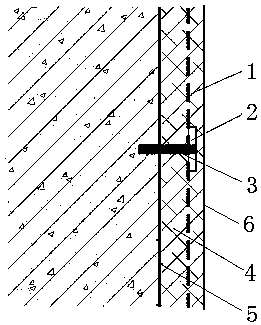

[0044] A dam body anti-seepage insulation layer is designed as follows: the surface is sprayed with a polyurea anti-seepage layer with a thickness of 2mm, a thermal insulation anchor structure, a polyurethane thermal insulation foam with a thickness of 10mm, and an anti-ice layer with a thickness of 3mm. The construction process is the following steps:

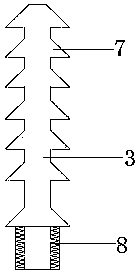

[0045] Step 1. After cleaning the concrete base material of the dam body, use the inner wire at the bottom of the screw to fix the 120mm length and 42mm diameter screw (the fixed thread length at the lower end is 30mm) in the screw hole left by the concrete pouring formwork, and use tape to protect the upper half of the screw .

[0046] Step 2. Use polyurethane or epoxy cement to repair the gap between the screw rod and the dam body, and at the same time repair serious defects on the concrete surface of the dam body.

[0047] Step 3. Construct polyurea with a thickness of 2 mm on the dam body as an anti-seepage coating, and p...

Embodiment 2

[0054] An anti-seepage and thermal insulation layer of a dam body is designed as follows: thermal insulation anchor structure, polyurethane thermal insulation foam with a thickness of 80 mm, and an anti-icing layer with a thickness of 5 mm. The construction process is the following steps:

[0055] Step 1. After cleaning the concrete base material of the dam body, use the inner wire at the bottom of the screw to fix the 100mm length and 36mm diameter screw (the fixed thread length at the lower end is 30mm) in the screw hole left by the concrete pouring formwork, and use tape to protect the upper half of the screw .

[0056] Step 2. Use polyurethane or epoxy cement to repair the gap between the screw rod and the dam body, and at the same time repair serious defects on the concrete surface of the dam body.

[0057] Step 3. Spray hard polyurethane foam with a thickness of 35 mm on the polyurea.

[0058] Step 4. Remove the protective tape on the upper part of the screw, bind the ...

Embodiment 3

[0063] The anti-seepage and thermal insulation layer of the dam body is designed as follows: thermal insulation anchor structure, 60mm thick polyurethane thermal insulation foam. The construction process is the following steps:

[0064] Step 1. After cleaning the concrete base material of the dam body, use the inner wire at the bottom of the screw to fix the 80mm length and 36mm diameter screw (the lower end fixed thread length is 30mm) in the screw hole left by the concrete pouring formwork, and use tape to protect the upper half of the screw .

[0065] Step 2. Use polyurethane or epoxy cement to repair the gap between the screw rod and the dam body, and at the same time repair serious defects on the concrete surface of the dam body.

[0066] Step 3. Spray hard polyurethane foam with a thickness of 25 mm on the polyurea.

[0067] Step 4. Remove the protective tape on the upper part of the screw, bind the glass fiber reinforcement with a diameter of 4mm on the screw, and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com