A desulfurization pump lined with resin silicon carbide

A technology of silicon carbide and desulfurization pumps, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as cracks, complex impeller shapes, and resin silicon carbide lining cracks, etc., to reduce The effect of craft difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

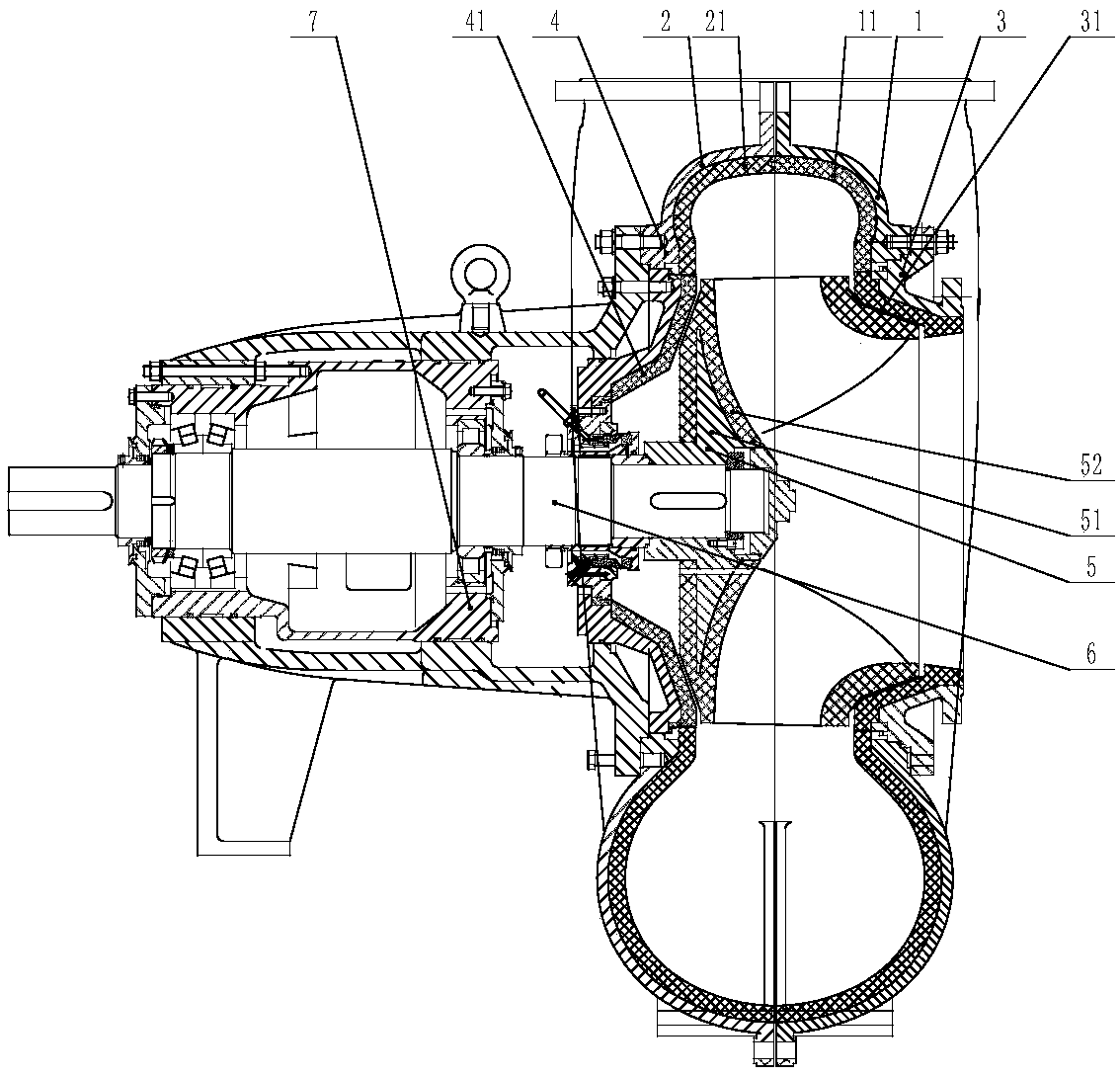

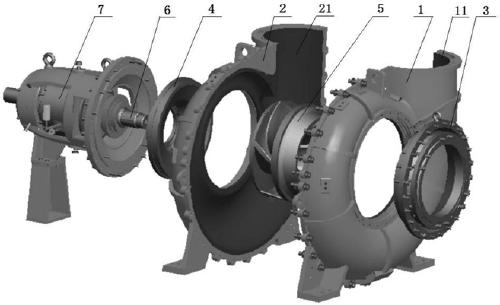

[0095] The technical scheme of the inventive resin-lined silicon carbide desulfurization pump and its preparation method will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention and implement it.

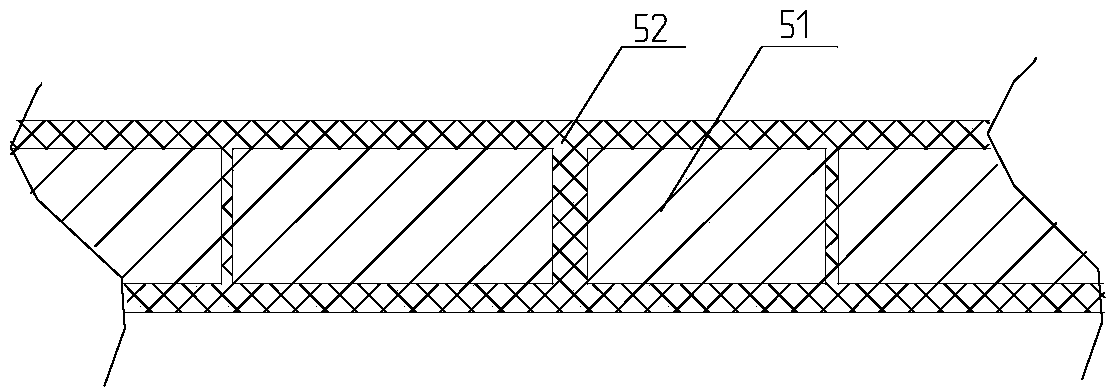

[0096] see figure 1 , the present invention provides a resin-lined silicon carbide desulfurization pump, comprising a pump body, a front pump cover 3 and a rear pump cover 4 arranged at both ends of the pump body, a pump shaft 6 passes through the rear pump cover 4 and extends into the pump body, and the end The impeller 5 is arranged, and the impeller 5 is axially fixed by the impeller bolts. The radial direction of the impeller 5 and the pump shaft 6 is fixed by a key connection. The other end of the pump shaft 6 is provided with a bearing assembly 7 and connected with the motor. In the desulfurization pump lined with resin silicon carbide of the present invention, the pump body is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com