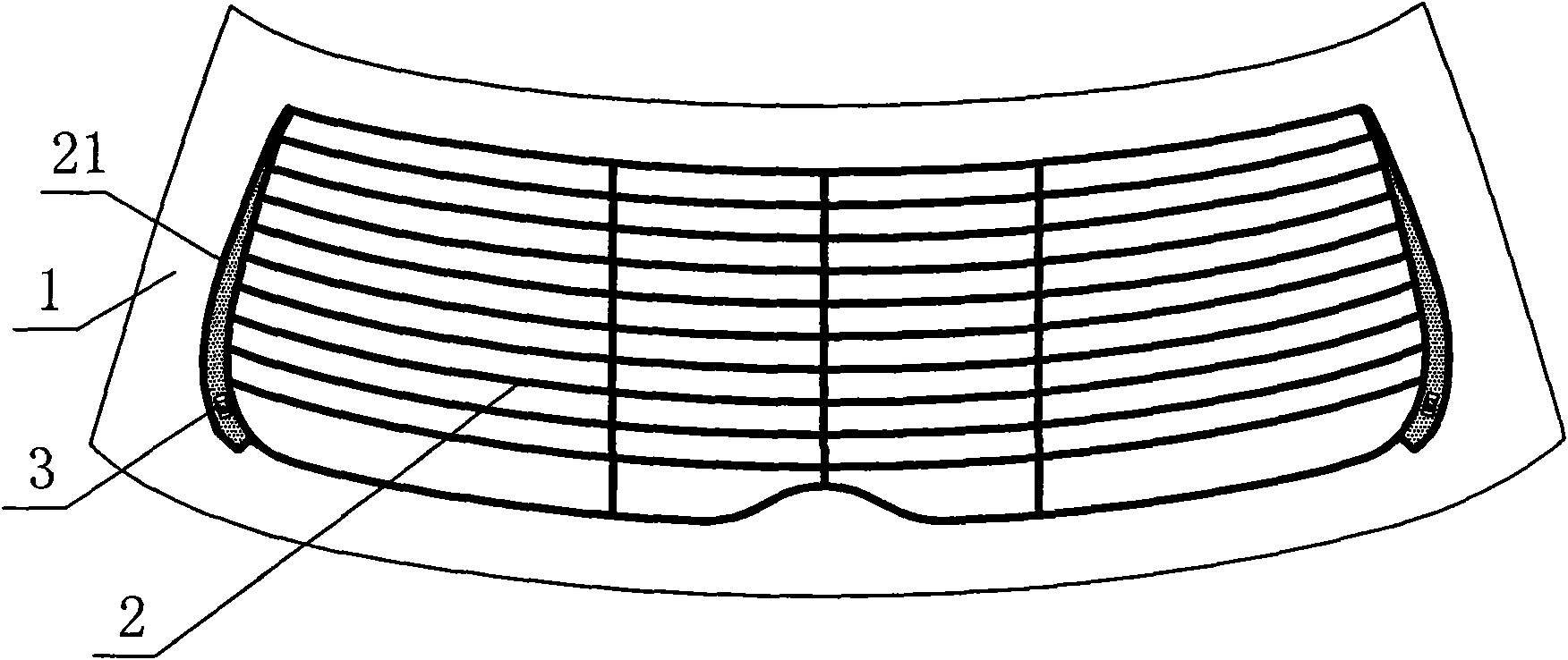

Method for welding tongue piece of automobile back windshield

A welding method and glass-shielding technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting welding stability, solder not melting, glass strength drop, etc., and achieve good welding quality, low price, and easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The automobile backshield tongue welding method of the present invention is characterized in that it is carried out according to the following steps:

[0018] (1) First make the cylindrical solder into a flat shape by knocking or pressing, and cut it into a solder sheet matching the size of the tongue, for use;

[0019] (2) Turn on the self-air temperature-adjusting plastic welding torch to preheat and set it aside;

[0020] (3) Wipe the silver paste on the glass surface to be welded with a glass fiber rod to remove the oxide layer;

[0021] (4) Place the solder sheet at the welding position, put the tongue on it, and then quickly heat it with a welding torch, and the solder is melted and the welding is completed;

[0022] (5) After welding, the glass is placed on a special rack for cooling.

[0023] The tongue piece welding method of the automobile rear windshield described in the present invention is simple and practical, and the equipment used is cheap and easy to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com