Fluid medium diversion structure for thermal isostatic-pressing working cylinder

A fluid medium, temperature isostatic pressing technology, applied in the direction of presses, manufacturing tools, etc., can solve problems such as product defects, and achieve the effect of making up for the temperature drop of the medium and promoting the distribution of the temperature field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below in conjunction with the accompanying drawings.

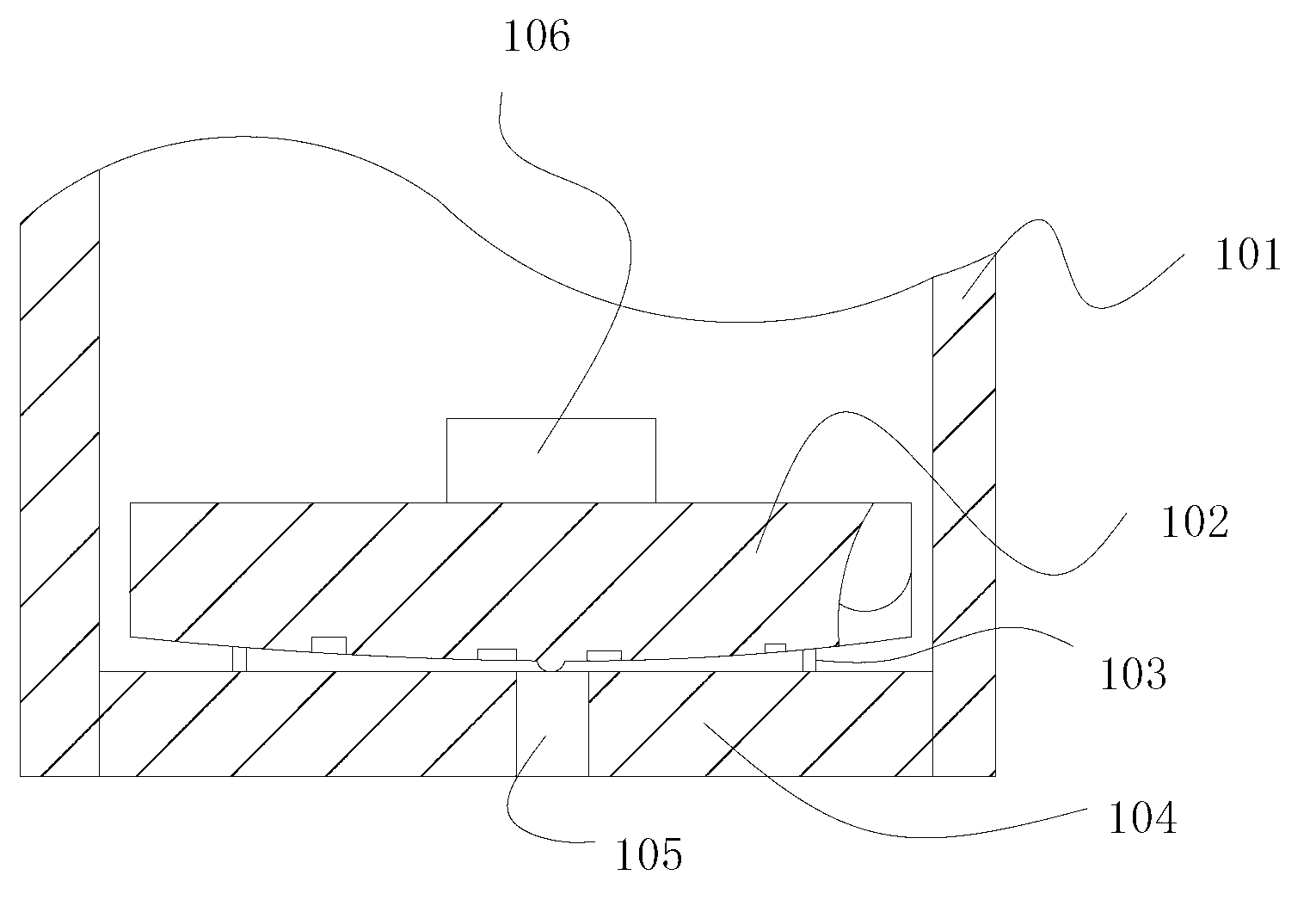

[0021] Such as figure 1 as shown, figure 1 A schematic structural diagram of an embodiment of the present invention is shown. This embodiment is used for the fluid medium shunting structure of the warm isostatic working cylinder, including the working cylinder body 101, the bottom of the working cylinder body 101 is provided with a lower end cover 104, and the lower end cover 104 is provided with a medium inlet 105, a certain temperature And ultra-high pressure liquid medium enters the cylinder body of the working cylinder from the medium inlet 105. If the size of the medium inlet 105 is too small, the inflow and outflow speed of the medium will be slow, resulting in heat loss of the medium. If the size of the medium inlet 105 is too large, the seal of the medium inlet 105 will easily leak under high pressure, especially an ultra-high pressure environment. As a pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com