High-strength glass, touch panel, and method for manufacturing high-strength glass

A manufacturing method and glass plate technology, applied in glass manufacturing equipment, manufacturing tools, glass production, etc., can solve the problems of long processing time and poor production efficiency, and achieve the goal of shortening processing time, improving production efficiency, preventing cracks and other damages. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

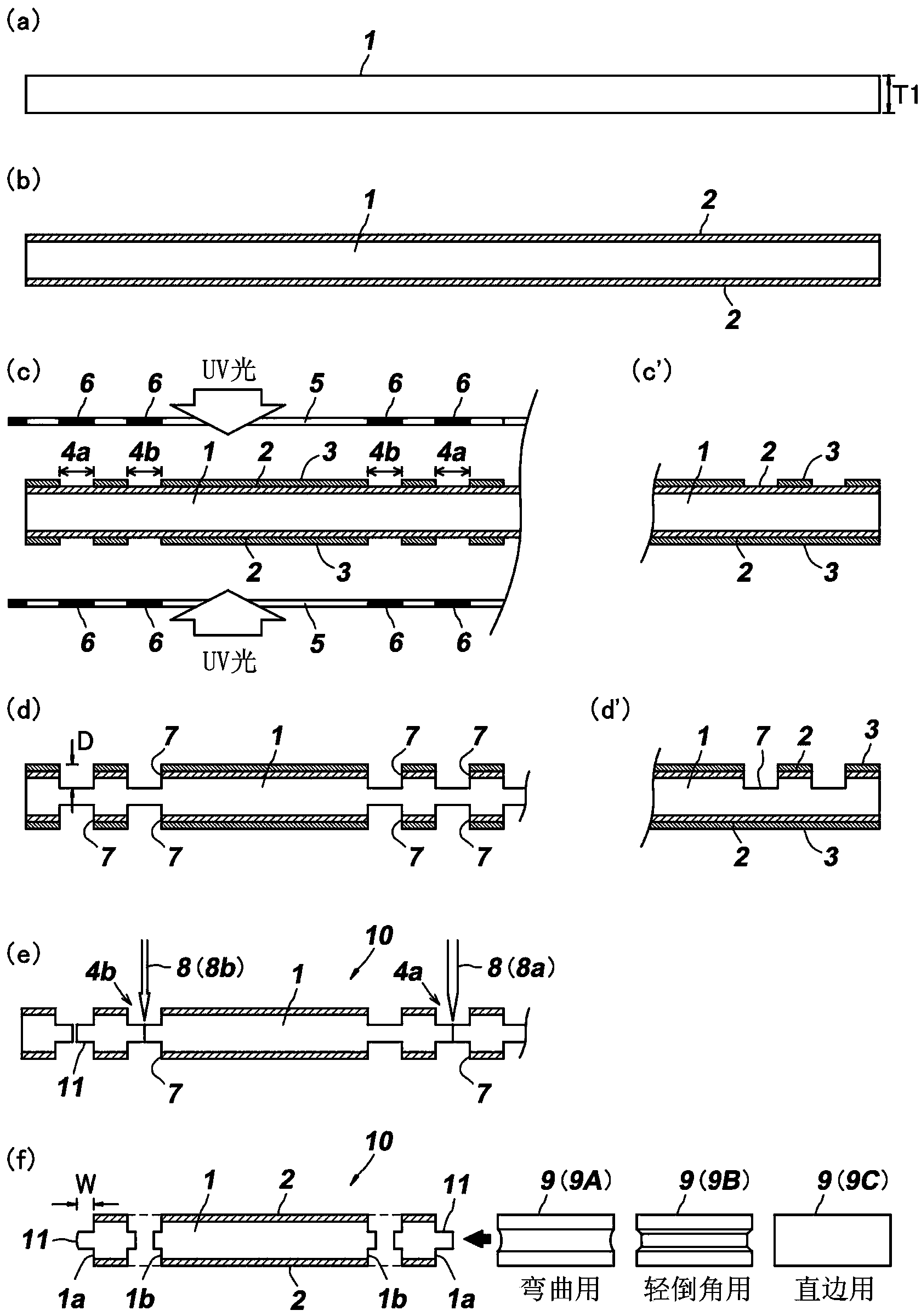

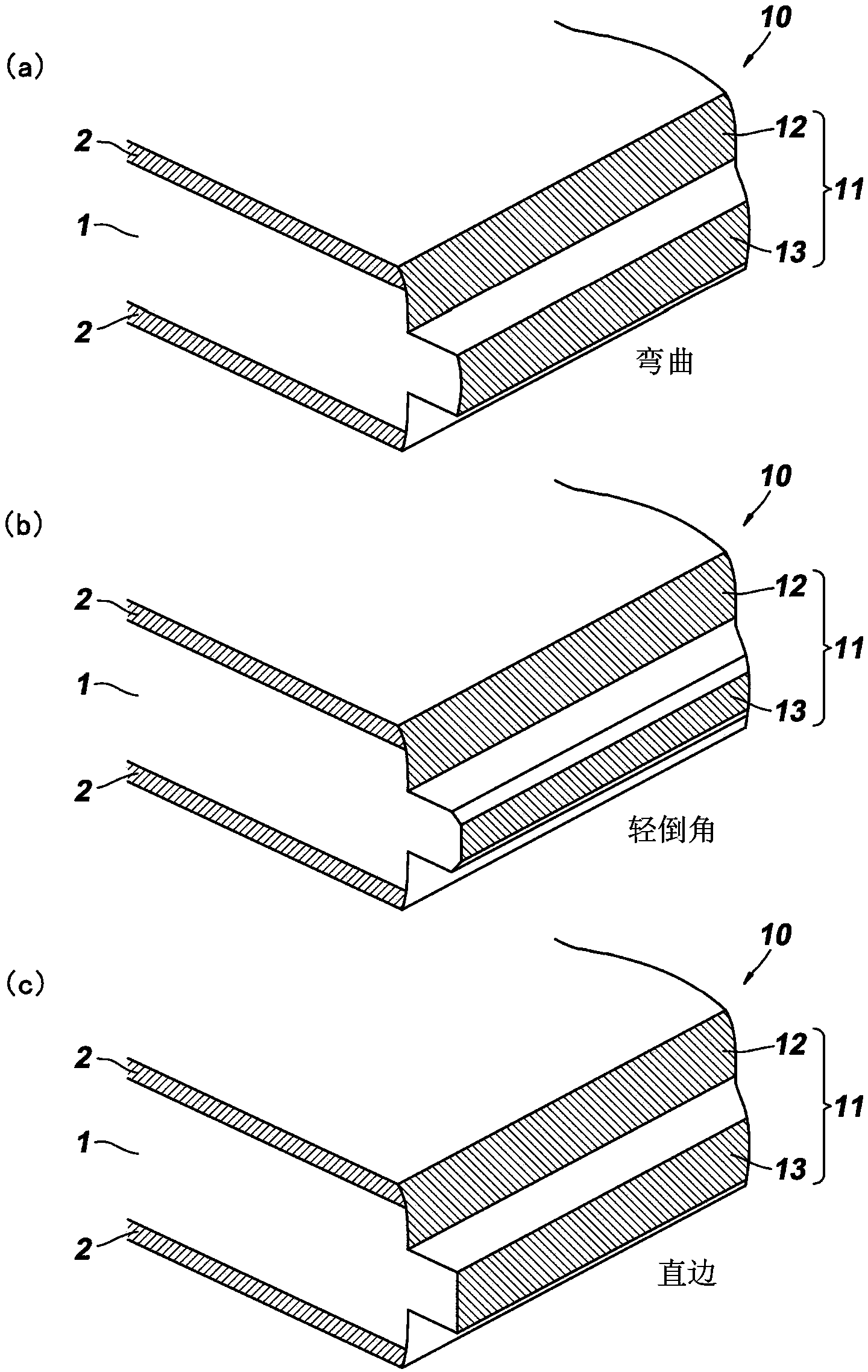

[0031] Hereinafter, modes for carrying out the present invention will be described with reference to the drawings.

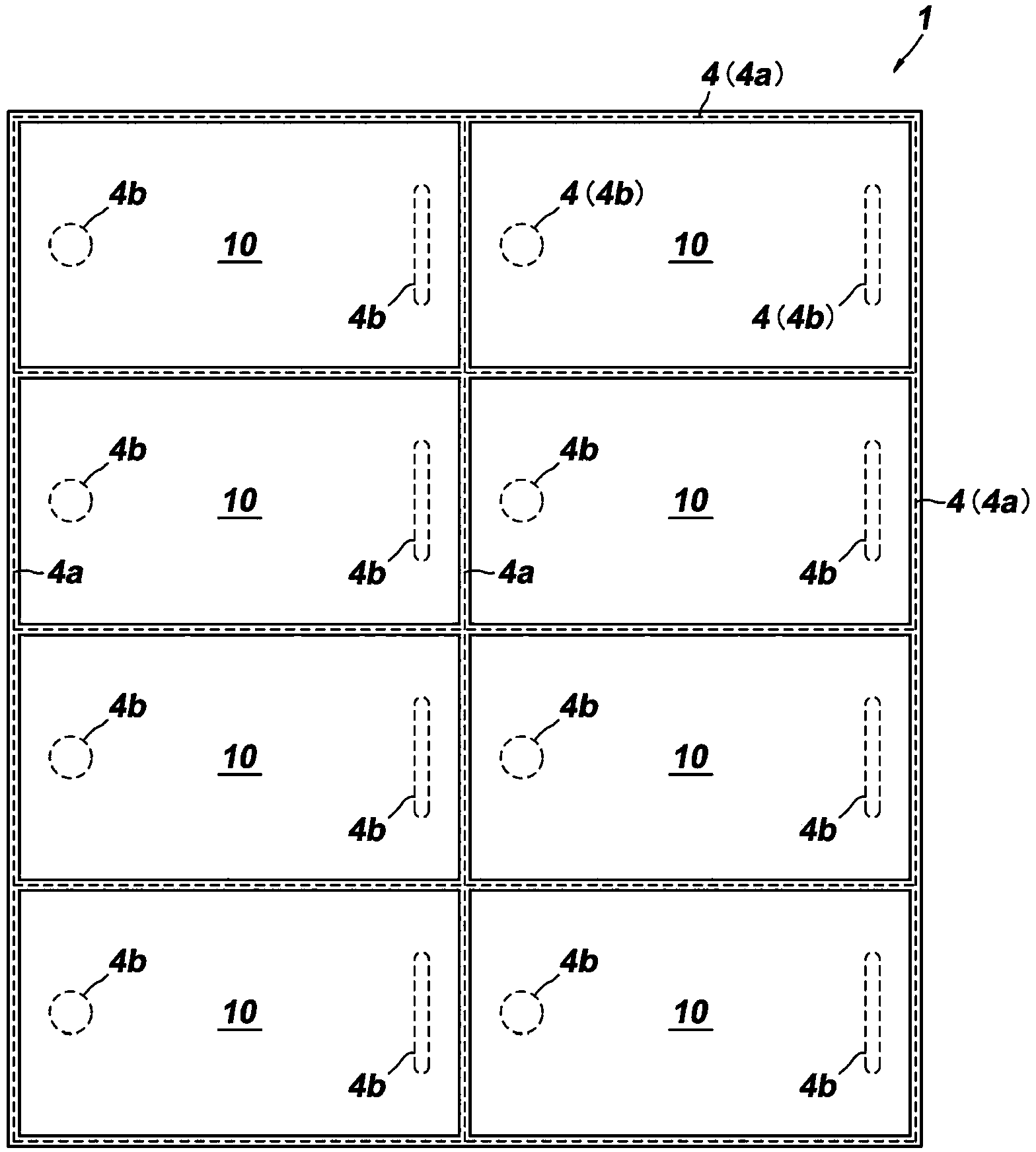

[0032] Such as figure 1 As shown, in the present invention, a thin and large glass plate 1 is used, and the single glass plate 1 is separated into pieces to manufacture a plurality of high-strength glasses 10 , 10 , . . . Hereinafter, the manufacturing method thereof will be described step by step. In addition, in the drawings referred to in the following description, in order to make the structure easy to understand, the characteristic part is shown enlarged compared with other parts, and differs from actual dimensional ratio.

[0033] Such as figure 2 As shown in (a), first, a thin and large glass plate 1 is prepared. The plate thickness T1 of the glass plate 1 is not particularly limited, but is preferably about 0.4 to 1.0 mm in consideration of thinning requirements, processability, and the like. In addition, the size of the glass plate 1 is, for exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com