Plastic case material for breaker and preparation method thereof

A shell material and circuit breaker technology, which is applied in the field of plastic shell materials for circuit breakers and its preparation, can solve the problems of poor toughness, insufficient heat resistance, and powder pollution of filled flame-retardant nylon bodies, and solve the problems of glass fiber exposure and warping bending problems, high breaking strength and modulus of elasticity, effects of high strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

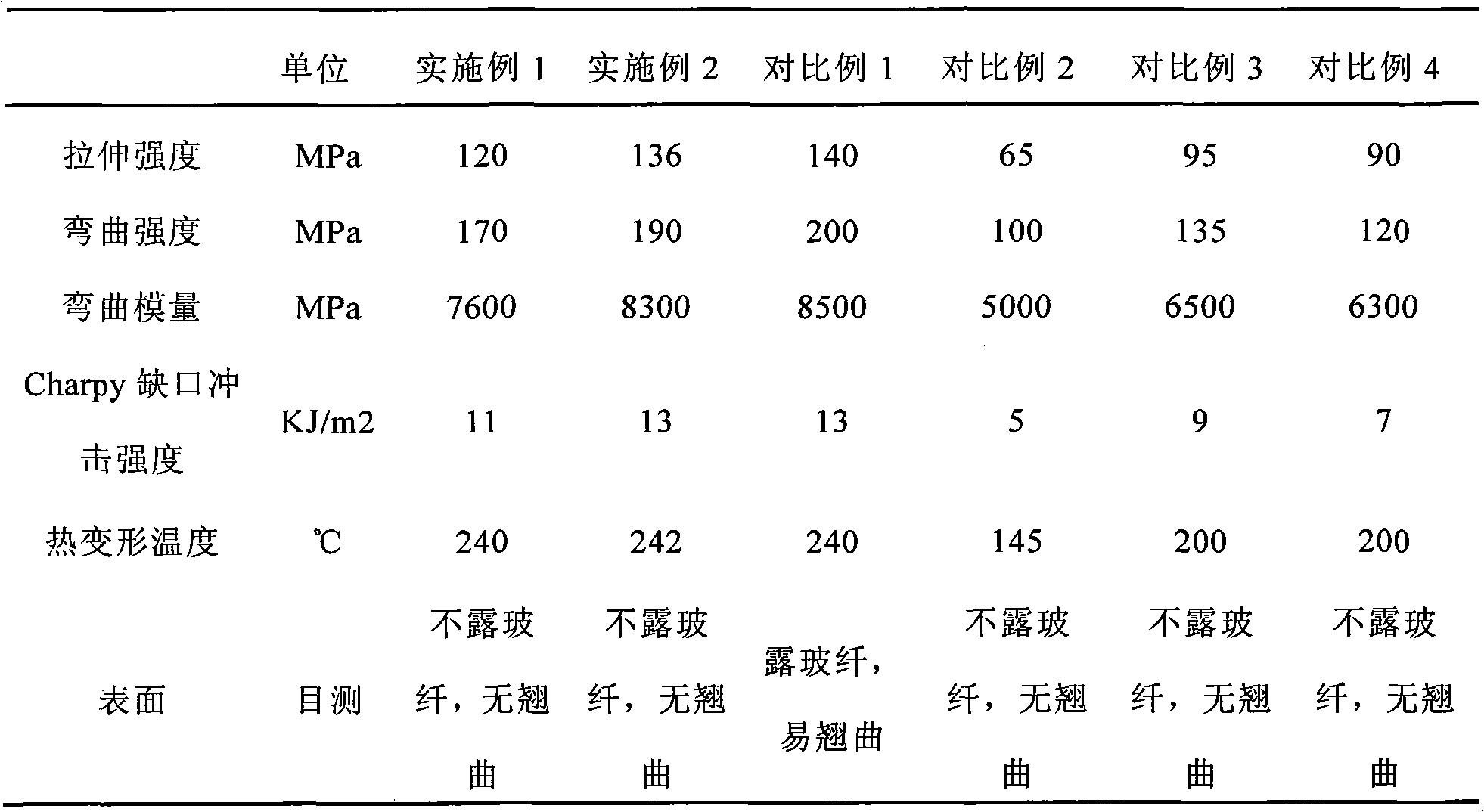

Examples

Embodiment 1-2

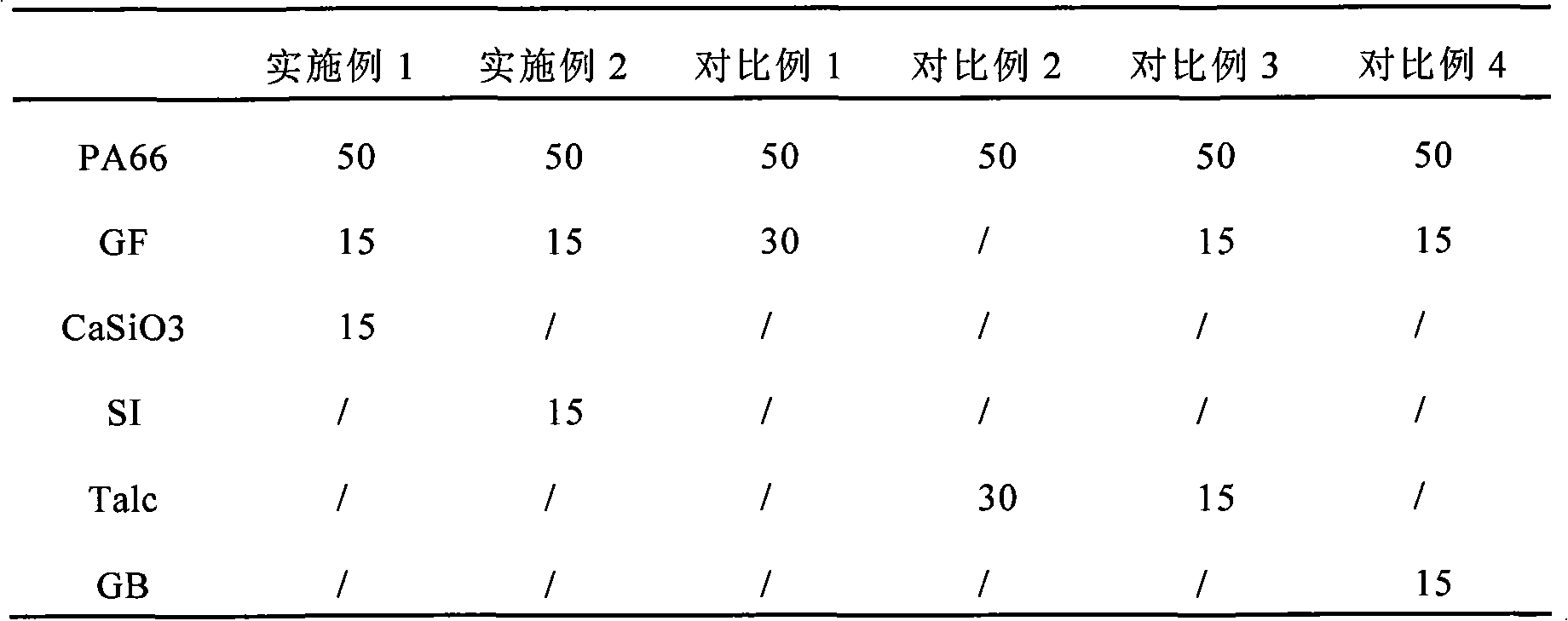

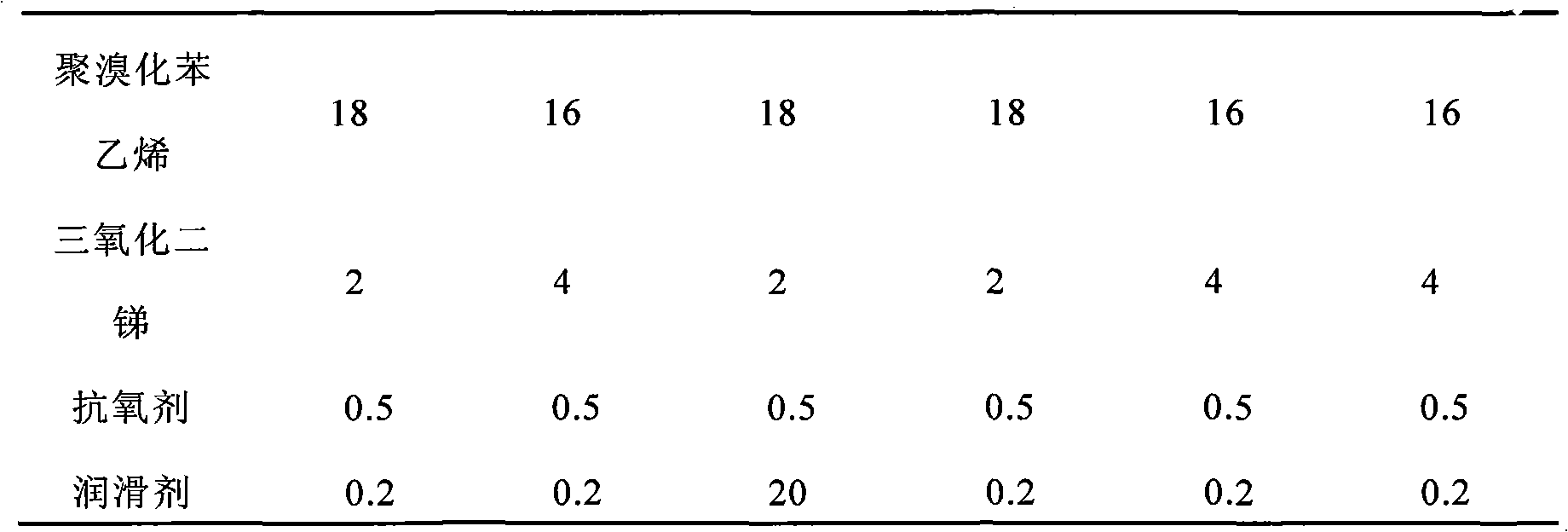

[0034] A method for preparing a plastic casing material for a circuit breaker, the method comprising the following steps:

[0035] (1) Material preparation: The required raw materials are as follows: PA66: nylon 66; GF: commercially available alkali-free glass fiber with a diameter of 13 μm; CaSiO 3 : commercially available wollastonite, with an aspect ratio of 60; SI: commercially available whisker silicon; Talc: commercially available talcum powder; GB: commercially available glass beads; polybrominated styrene; antimony trioxide; antioxidant : Irganox 1098 produced by Ciba Specialty Chemicals, Switzerland; lubricant: ethylene vinyl acetate copolymer. The content of each component is shown in Table 1.

[0036] (2) Put nylon resin, glass fiber, filler, flame retardant and various additives through a high-speed mixer, control the stirring rate at 800-1000rpm for high-speed mixing, and then control the process temperature at 250-290°C, The composition can be obtained by carry...

Embodiment 3

[0047] A method for preparing a plastic casing material for a circuit breaker, the method comprising the following steps:

[0048] (1) Prepare raw materials according to the following components and contents: nylon 622g, alkali-free glass fiber 25g, commercially available silicon carbide whiskers 25g, commercially available melamine 20g and silicone 6g, commercially available heat stabilizer TNP 0.05g, commercially available UV Stabilizer 0.05g. The diameter of the alkali-free glass fiber is 6 μm.

[0049] (2) Control the speed of the high mixer to 800-1000rpm, mix the above raw materials at a high speed through the high mixer, and then control the temperature to 220-270°C, and cut the mixture into pellets through a twin-screw extruder. product.

Embodiment 4

[0051] A method for preparing a plastic casing material for a circuit breaker, the method comprising the following steps:

[0052](1) Prepare raw materials according to the following components and contents: nylon 6680g, alkali-free glass fiber 5g, commercially available silicon nitride whiskers 5g, commercially available red phosphorus 8g and antimony trioxide 2g, commercially available lubricant silicone oil 0.5g, 0.5 g of commercially available silane coupling agent, 0.5 g of commercially available processing stabilizer calcium stearate, and 0.5 g of commercially available nucleating agent EPR. Among them, the diameter of the alkali-free glass fiber is 18 μm.

[0053] (2) Control the speed of the high mixer to 800-1000rpm, mix the above raw materials at a high speed through the high mixer, and then control the temperature to 220-290°C, and cut the mixture into strands through a twin-screw extruder to obtain product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com