Mounting structure of automobile rear skin assembly

An installation structure and assembly technology, which is applied to the superstructure, the subassembly of the superstructure, vehicle parts, etc., can solve the problems of difficult disassembly and assembly of the rear skin assembly, and achieves the solution of inconvenient disassembly and assembly, convenient disassembly and assembly, and a solution Effects of Assembly Dimension Deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

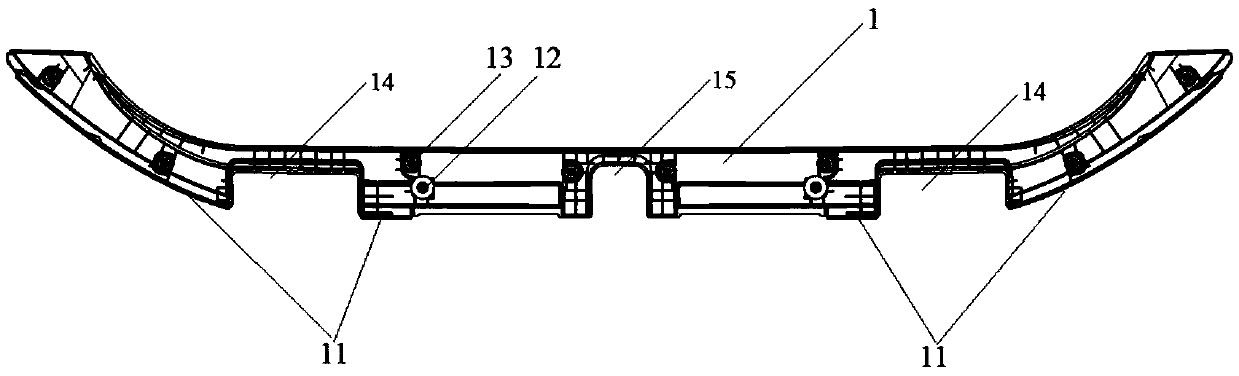

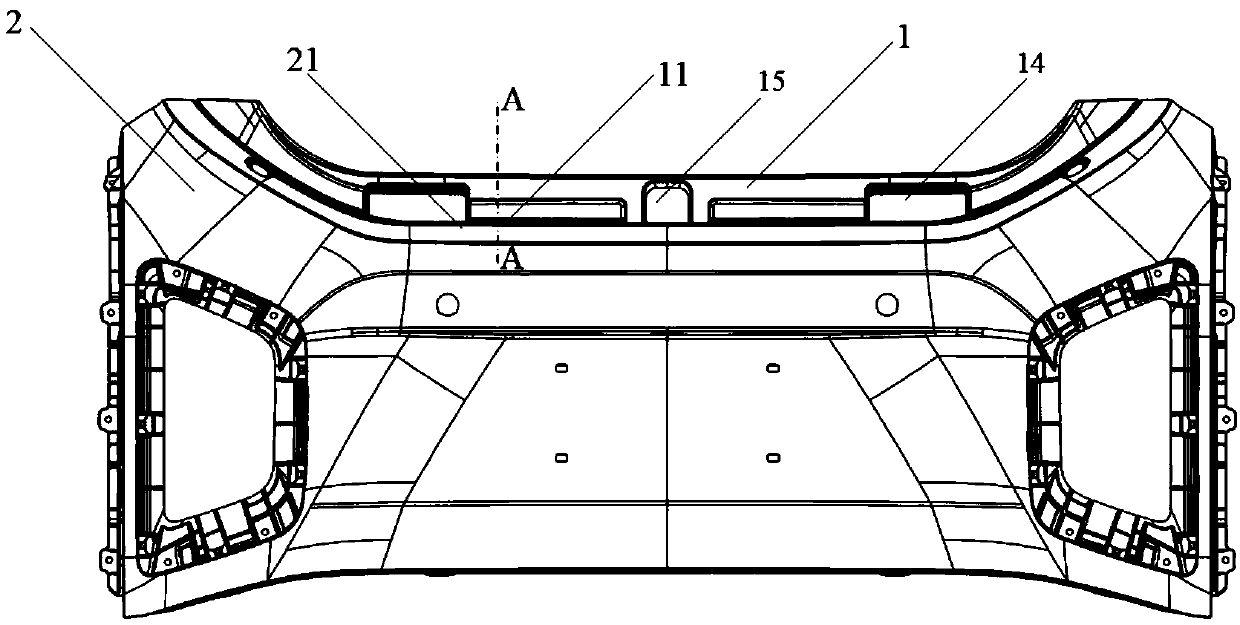

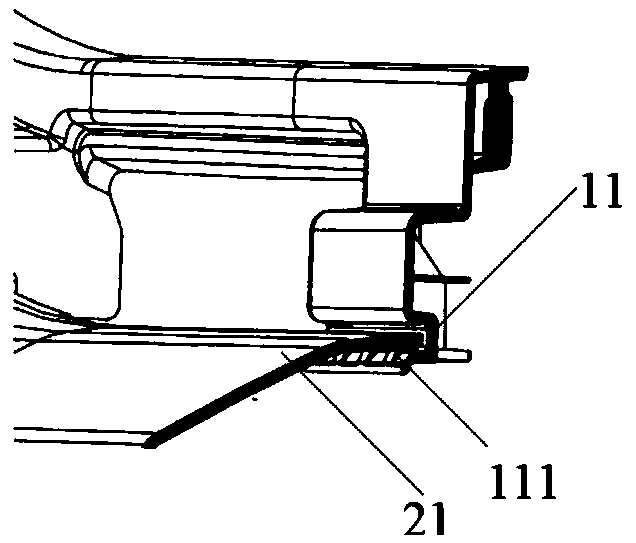

[0023] The structure of the installation structure of a car rear skin assembly 2 in the embodiment of the present invention is as follows: Figure 1~3 As shown, it includes: rear skin assembly 2, a bow-shaped upper decorative panel assembly 1 located on the rear The upper flange 21 is provided at the adjoining position of the upper decorative panel assembly 1 in the shape matching with the C-shaped groove 11 and capable of being inserted into the C-shaped groove 11 .

[0024] In this embodiment, the installation structure mainly includes two parts, the rear skin assembly 2 and the upper trim panel assembly 1 . The shape of the upper trim panel assembly 1 is approximately bow-shaped, and it is located on the rear skin assembly 2 during installation. The lower edge of the upper decorative panel assembly 1 is provided with a C-shaped groove 11 , and the rear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com