Pipeline flexible anti-floating device and pipeline mounting method

A pipeline installation and pipeline technology, which is applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of air corrosion, life reduction, underground device erosion, etc., and achieve convenient manual installation and durable reinforcement effect , the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A pipeline installation method is provided: firstly, it is necessary to determine the construction location, excavate the foundation pit with a long-arm excavator, excavate in layers and sections, excavate the excavated earth and load it away by truck; backfill and compact the over-excavated part to the design height to ensure the foundation Meet the design strength requirements, and ensure the flatness of the excavation surface; after the foundation trench is repaired, remove the debris and floating soil on the foundation, and use the sand and gravel cushion as the foundation cushion to form a construction trench.

[0045] Further, after the excavation of the construction trench is completed, the operator needs to lay the pipeline concave flexible base at equal intervals along the pipeline laying length of 1000mm and place it on the center line of the trench. The concave flexible base of the pipeline is filled with sand, pulverized coal Gray and other flexible materials...

Embodiment 2

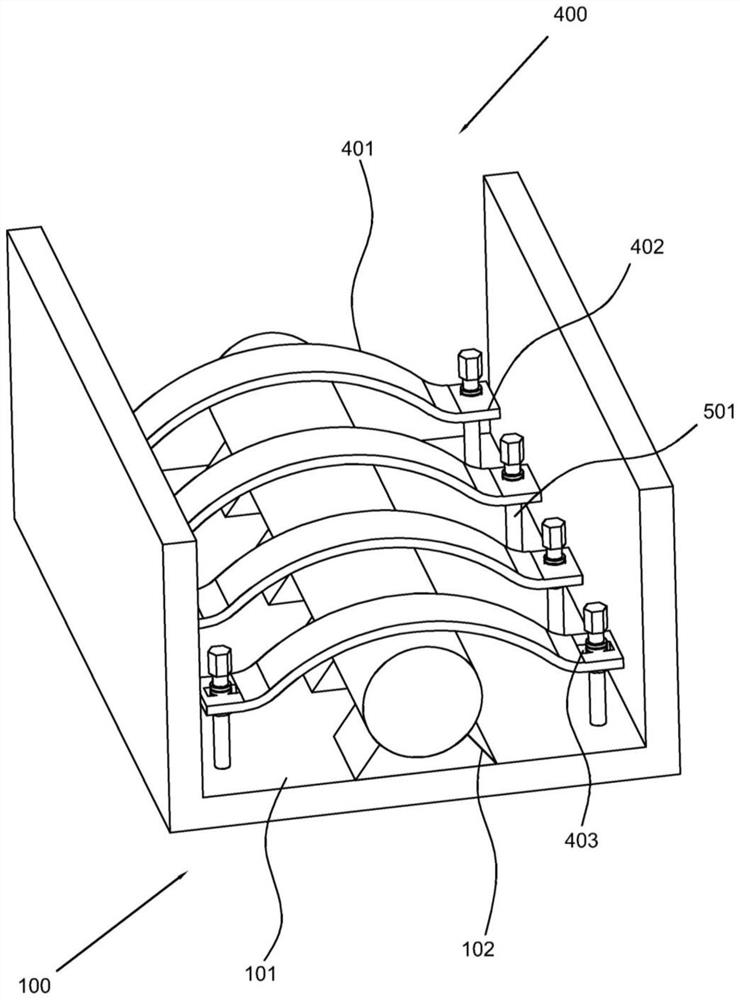

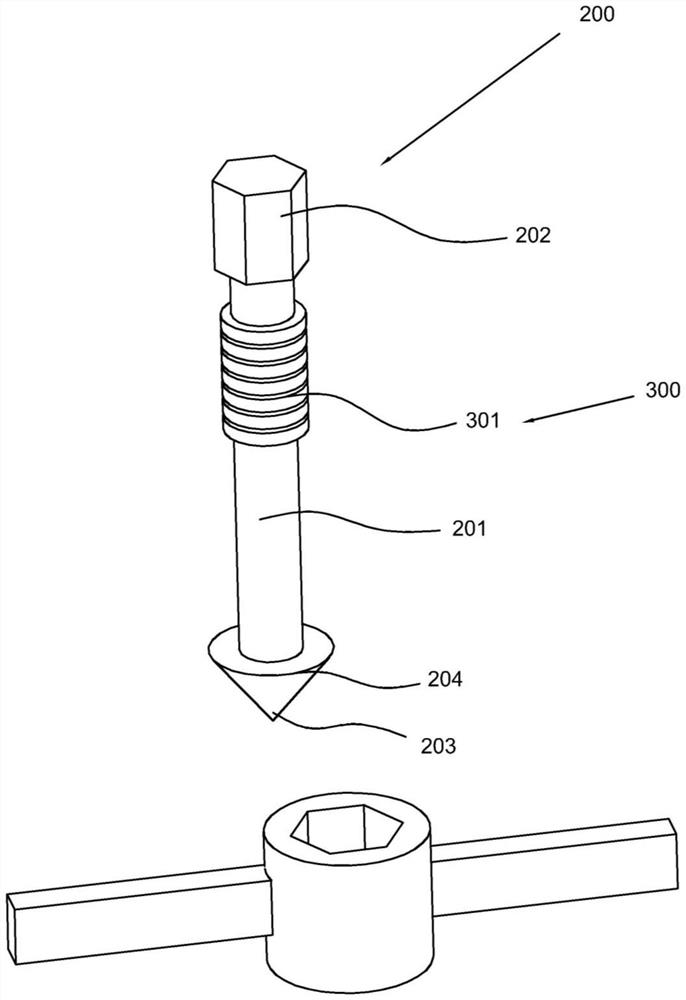

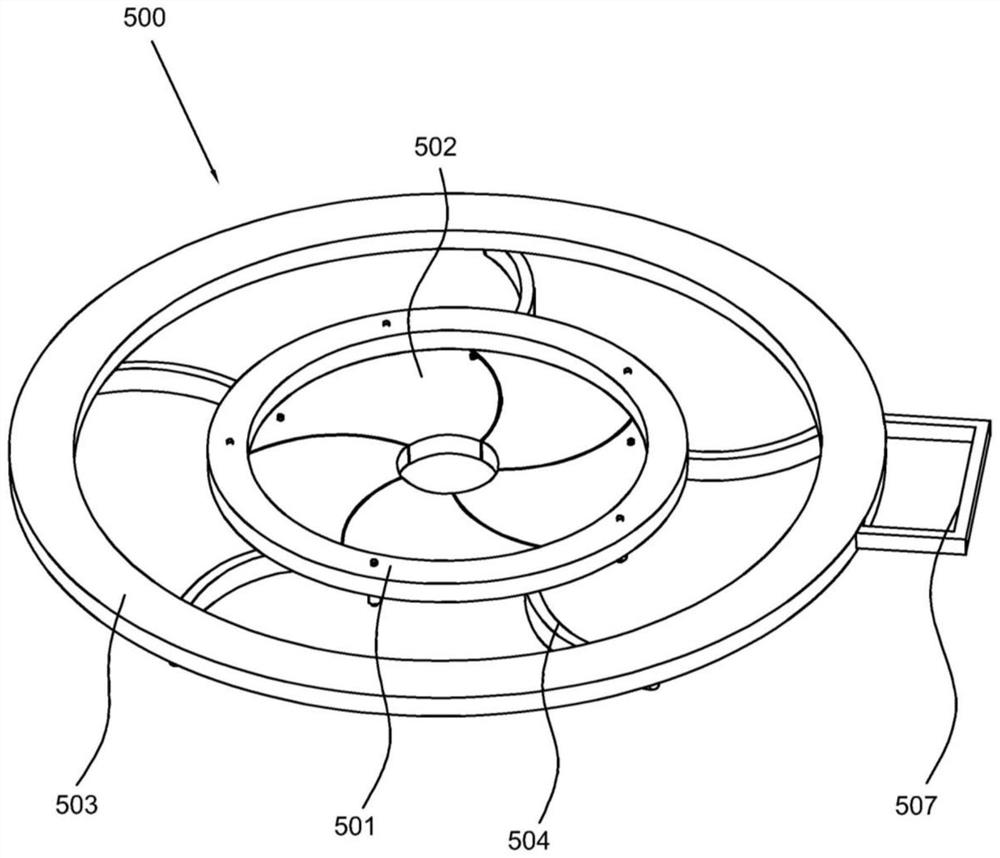

[0051] refer to Figure 1-4 , provides a flexible anti-floating device for pipelines, including a groove assembly 100, including a base groove 101, a base 102 disposed in the base groove 101, and a placement groove opened on the base 102; a pipeline anchor assembly 200, It includes a rod body 201, an octagonal nut 202 arranged at the upper end of the rod body 201, and a drill bit 203 arranged at the lower end of the rod body 201. A helical blade 204 is arranged between the drill bit 203 and the rod body 201. and the buckle assembly 300, the buckle assembly 300 is arranged between the pipeline and the rod body 201, the diameter of the bottom of the helical blade 204 is the same as that of the rod body 201, the diameter of the top of the helical blade 204 is 2-3 times the diameter of the rod body 201, and the helical The height of the blade 204 is 2-3 times the transverse diameter of the helical blade 204. The buckle assembly 300 includes a number of prisms 301 arranged at the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com