Formula and preparation process for sandbox molding sand

A sand box molding and preparation technology, which is applied to casting molding equipment, manufacturing tools, casting molds, etc., can solve the problems of insufficient strength, thermal stability, plasticity, air permeability, and poor collapse, and achieve easy demoulding and smooth inner wall Effect of low roughness and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

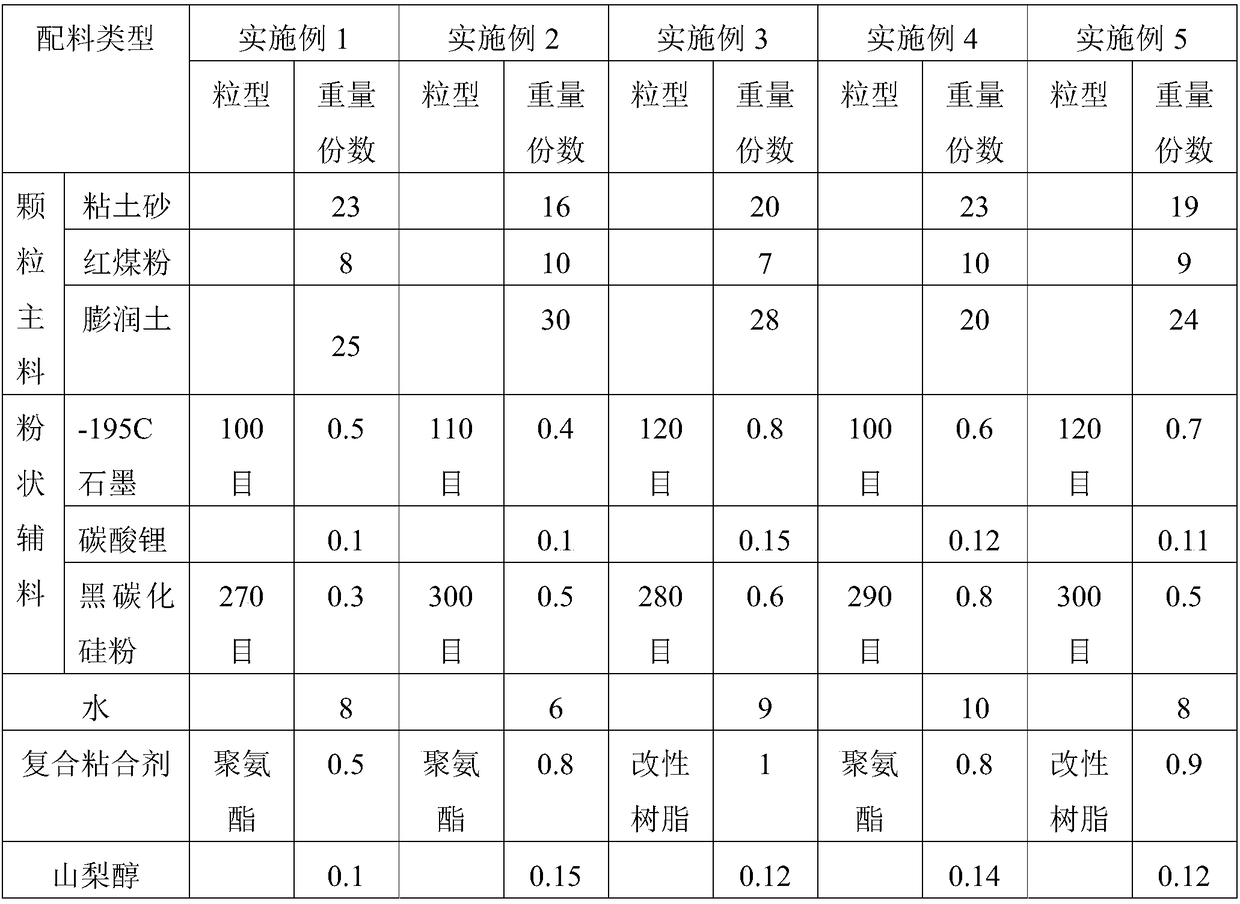

[0034] A sand box molding sand formulation of the present embodiment is composed of the following components in parts by weight: the main particle material includes: 23 parts of clay sand, 25 parts of bentonite, and 8 parts of red coal powder; the powdery auxiliary material includes 0.1 part of lithium carbonate , 0.3 parts of black silicon carbide powder, 0.5 parts of -195C graphite, 8 parts of water, 0.5 parts of composite binder and 0.1 part of sorbitol. 2 O content is 0.5% by weight or less, K 2 The content of O is less than 0.5% by weight, the content of CaO is less than 0.5% by weight, the composite binder is a polyurethane binder, the particle type of black silicon carbide powder is 270 mesh, and the SiC content is 99.5%; the particle size of -195C graphite The type is 100 mesh, and the C content is 97.8%.

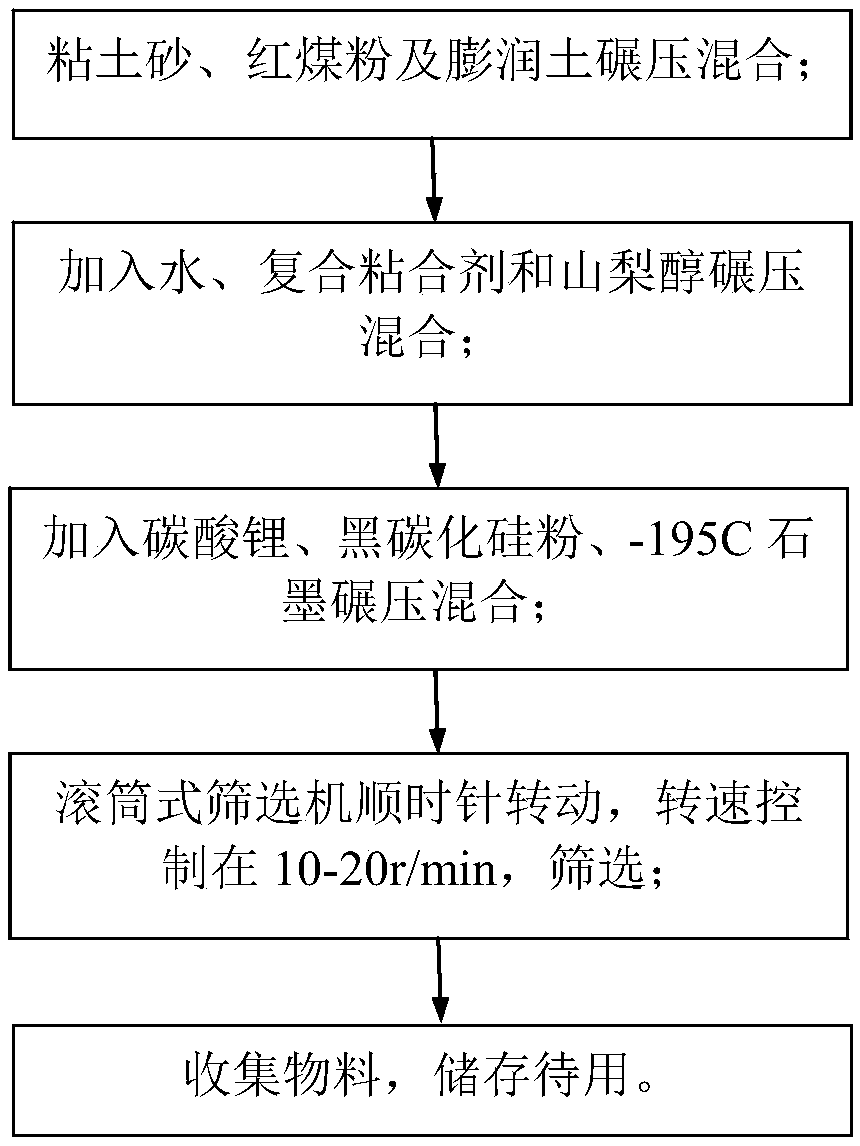

[0035] The sand box molding sand formulation preparation process of the present embodiment, such as figure 1 shown, including the following steps:

[0036] Step ...

Embodiment 2

[0044] A sand box molding sand formulation of the present embodiment is composed of the following components in parts by weight: the main particle material includes: 16 parts of clay sand, 30 parts of bentonite, and 10 parts of red coal powder; the powdery auxiliary material includes 0.1 part of lithium carbonate , 0.5 parts of black silicon carbide powder, 0.4 parts of -195C graphite, 6 parts of water, 0.8 parts of composite binder and 0.15 parts of sorbitol. 2 O content is 0.5% by weight or less, K 2 The content of O is less than 0.5% by weight, the content of CaO is less than 0.5% by weight, the composite binder is a polyurethane binder, the particle type of black silicon carbide powder is 300 mesh, and the SiC content is 99.4%; the particle size of -195C graphite The type is 110 mesh, and the C content is 98.5%.

[0045] The sand box molding sand formula preparation process of the present embodiment comprises the following steps:

[0046] Step S101, rolling and mixing

...

Embodiment 3

[0054] A sand box molding sand formula of the present embodiment is composed of the following components in parts by weight: the main particle material includes: 20 parts of clay sand, 28 parts of bentonite, and 7 parts of red coal powder; the powdery auxiliary material includes 0.15 parts of lithium carbonate , 0.6 parts of black silicon carbide powder, 0.8 parts of -195C graphite, 9 parts of water, 1 part of composite binder and 0.12 parts of sorbitol. 2 O content is 0.5% by weight or less, K 2 The content of O is less than 0.5% by weight, the content of CaO is less than 0.5% by weight, the composite binder is a modified resin binder, the particle size of black silicon carbide powder is 280 mesh, and the SiC content is 99.5%; -195C graphite The particle type is 120 mesh, and the C content is 99%.

[0055] The sand box molding sand formula preparation process of the present embodiment comprises the following steps:

[0056] Step S101, rolling and mixing

[0057] Clay sand,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com