Plastic mold internal screw thread floating stopping demolding mechanism

A technology of plastic mold and demoulding mechanism, applied in the field of plastic mold, can solve the problems of demoulding failure, loss, and no anti-rotation device, etc., and achieve the effect of smooth demoulding action, low cost investment and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

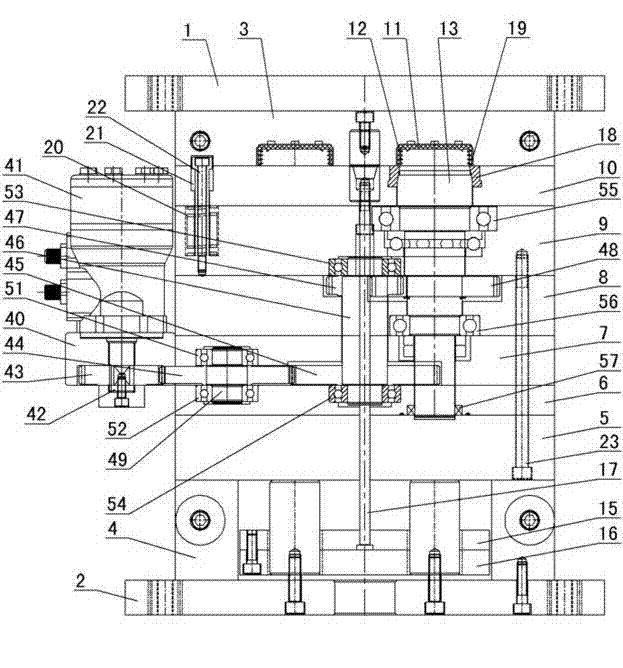

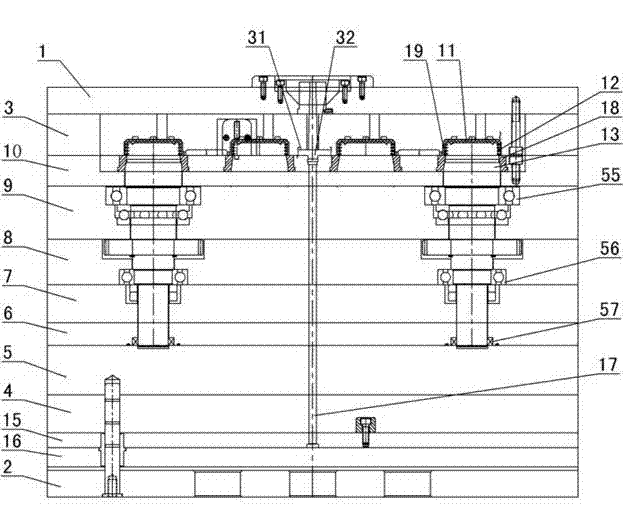

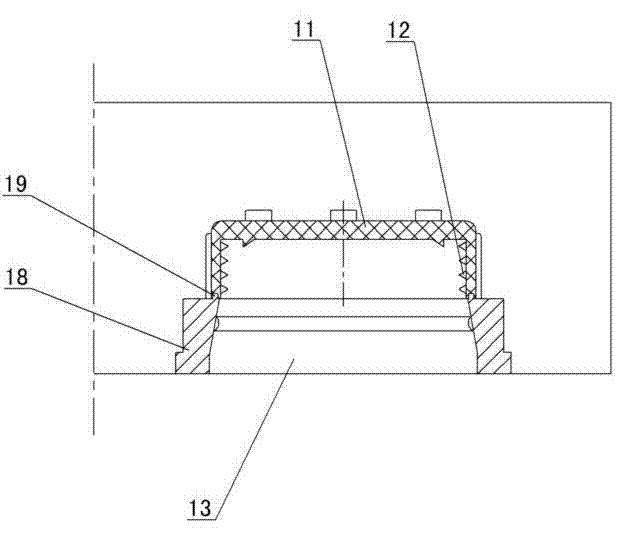

[0010] The invention relates to a plastic mould's internal thread floating stop-rotation demoulding mechanism, such as figure 1 — image 3 As shown, it includes the upper doubler plate 1 and the lower doubler plate 2 of the mold, the fixed formwork 3 is installed under the upper doubler plate, and the fixed formwork 3 is formed with a flow channel 31, and two mold feet 4 are installed on the lower doubler plate 2, and the upper doubler plate Install the movable mold bottom plate 5, the lower gear fixed plate 6 and the upper gear fixed plate 7 are arranged on the movable mold bottom plate, the transition gear fixed plate 8 is installed on the upper gear fixed plate 7, the movable mold seat plate 9 is installed on the transition gear fixed plate, and the movable mold A movable template 10 is installed on the seat plate 9, and there is an injection molding cavity between the movable template 10 and the fixed template 3, and a molded product 11 is formed in the cavity, and an inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com