Method for glazing specular gloss on paper surfaces

A specular gloss and paper technology, applied in papermaking, textiles and papermaking, fiber raw material processing, etc., can solve the problems of many operating procedures, expensive equipment, complicated procedures, etc., and achieve the effect of reliable technology, easy peeling, simple and practical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

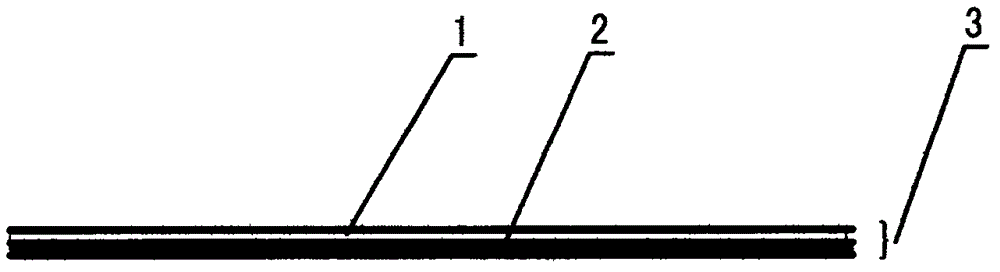

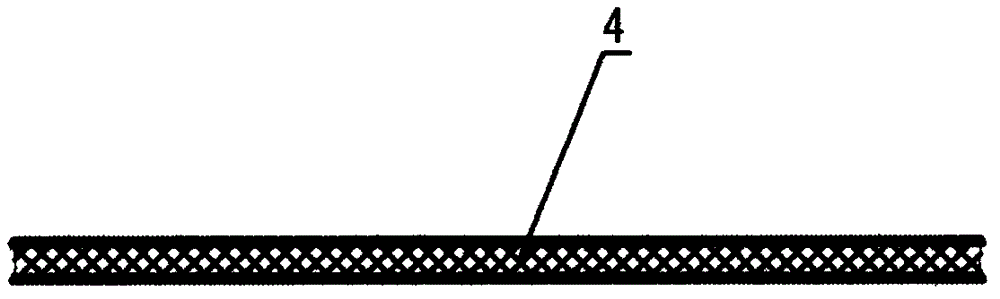

Image

Examples

Embodiment

[0038] Embodiment: the manufacturing process is as follows:

[0039] a, preparation of composite varnish resin: under normal temperature and pressure, add any commercially available coloring matter between 0-30% by weight in the commercially available varnish resin to prepare a composite varnish resin as a transfer material, and prepare Requirements: The fineness of pigment powder powder particles is 800 mesh-1500 mesh, and the viscosity of the compound varnish resin after uniform stirring and preparation is 10S-50S / T4, which is ready for use; the "commercially available varnish resin" mentioned here is Refers to: the release agent of the traditional transfer method, or various water-soluble varnish resins for mirror surface glazing in the prior art, or water-based acrylic resins. The varnish resins here can be selected individually or can be used with each other Composite composition; the "commercially available colorants" here refer to: commercially available soluble dyes of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com