Thermoplastic elastic body for jetting and adhibiting with ABS at low-temperature

A technology of thermoplastic elastomer and thermoplastic polyurethane, which is applied in the field of thermoplastic elastomer, can solve the problems of low thermal deformation temperature and easy deformation of ABS resin, and achieve good adhesion performance and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

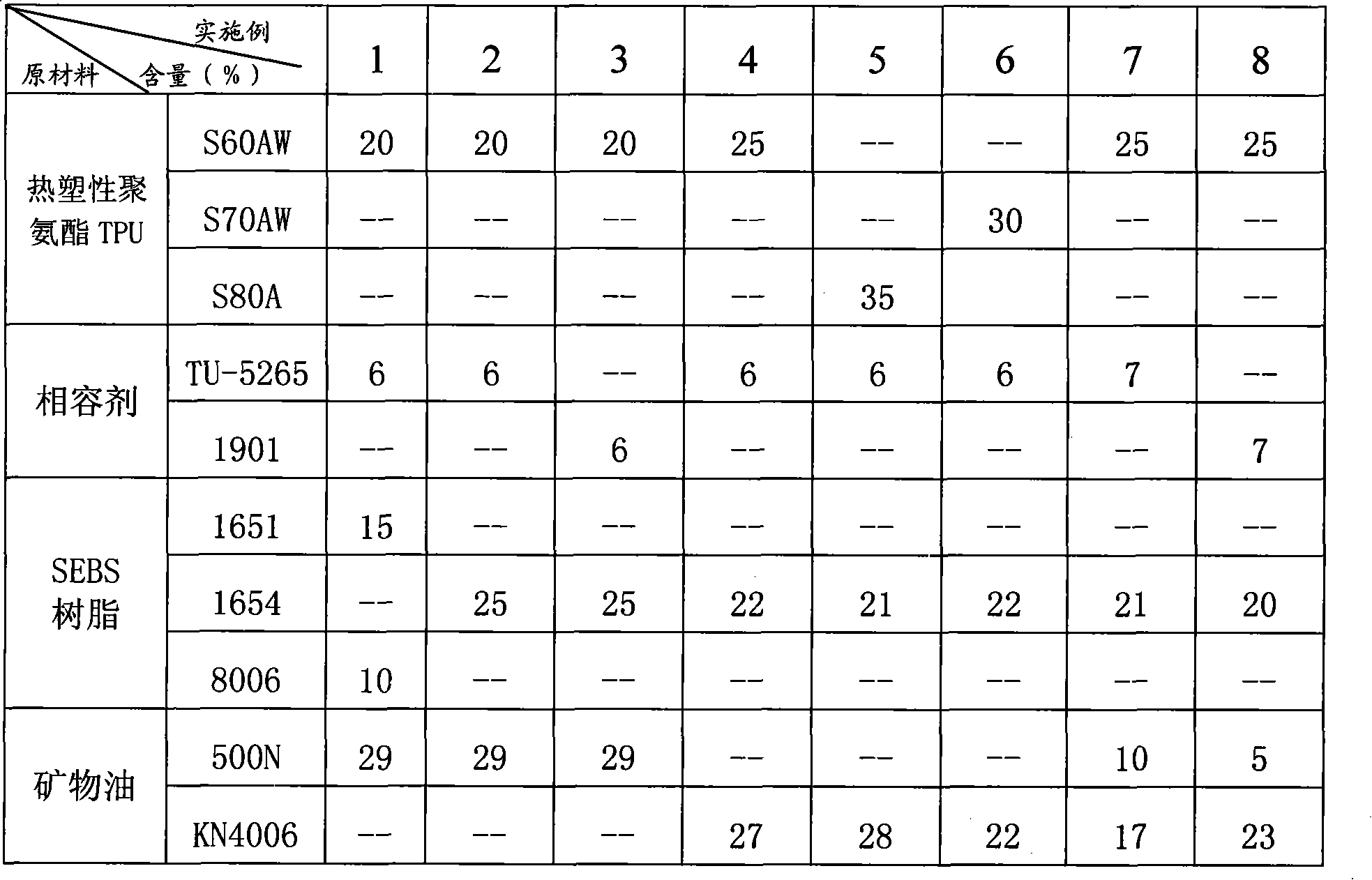

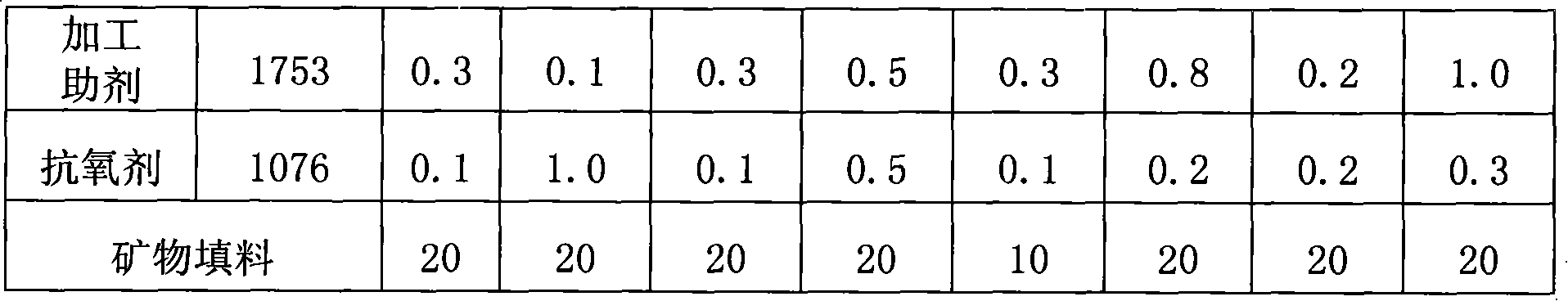

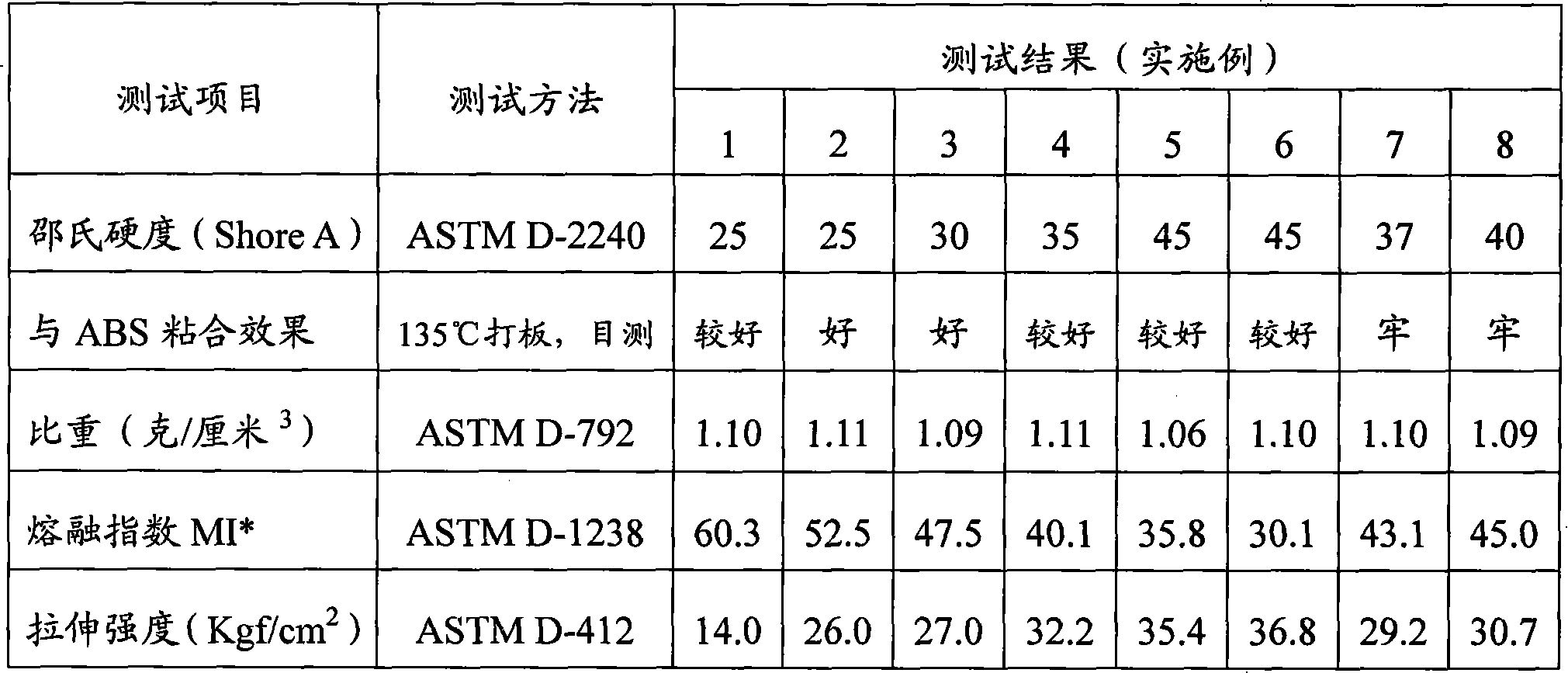

[0021] 1. Raw material ratio

[0022]

[0023]

[0024] Among the above raw materials, the compatibilizer TU-5265 and 1901 can be replaced by other SEBS-co-TPU and SEBS-g-MAH of the same type;

[0025] Mineral oil 500N and KN4006 can be replaced by other saturated linear paraffin oil or naphthenic oil with a flash point higher than 200°C;

[0026] The auxiliary agent 1753 can be replaced by other suitable fatty acids, fatty acid amides, polysilicone;

[0027] The antioxidant 1076 can be replaced by other similar antioxidants 1010, 168;

[0028] The mineral filler is one or a mixture of calcium carbonate, talcum powder, gypsum powder, asbestos powder, clay, barium sulfate, mica powder, and kaolin.

[0029] 2. Injection molding

[0030] Take the raw material components according to the above-mentioned ratios, mix SEBS and mineral oil thoroughly, absorb the oil, add compatibilizer, TPU, additives, antioxidants, mineral fillers, etc., and mix evenly in the mixer. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com