Stereo lithography apparatus (SLA)-based 3D printing implementation method and device

A technology of 3D printing and realization method, applied in the field of 3D printing, it can solve the problems that the surface has no effect and cannot meet the requirements of people's product appearance, and achieve rich and diverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

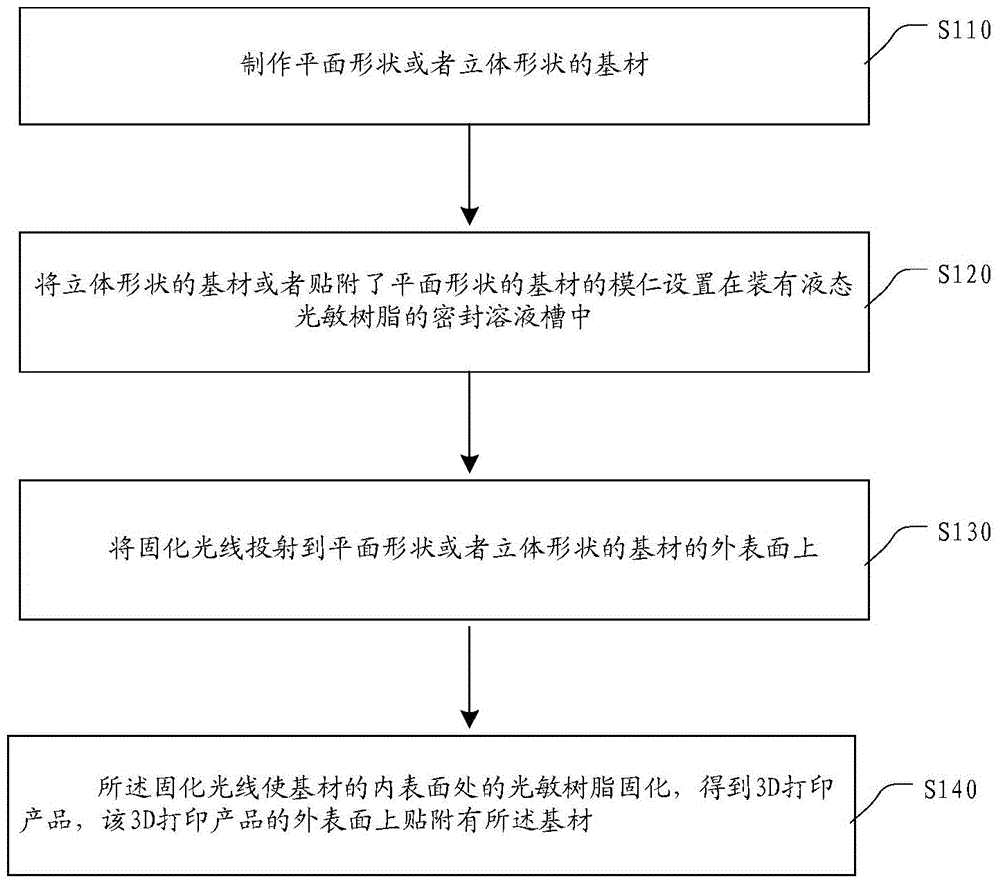

[0052] In order to enrich the surface effects of SLA-based 3D printing products, an embodiment of the present invention provides a method for implementing SLA-based 3D printing. The specific processing flow of the method is as follows: figure 1 As shown, the following processing steps are included:

[0053] Step S110, making a planar or three-dimensional base material.

[0054] In-mold decoration technology has been widely used in the field of injection molding. In-mold decoration technology can be used to replace the traditional process of spraying paint, printing, electroplating and other processes after the parts are formed. In addition, it can also achieve realistic pattern decoration effects that cannot be achieved by traditional processes. The degree of exquisite appearance is beyond the reach of traditional surface decoration processes. within reach.

[0055] The film or leather with surface effect is used as the base material, and the base material can be a film used...

Embodiment 2

[0080] This embodiment provides a device for realizing 3D printing based on photocuring rapid prototyping, and its specific structure is as follows Figure 8 As shown, it includes: a sealing solution tank 81 , a planar substrate 82 , a curing light source 83 , a mold core 84 and a movement control mechanism 85 . Liquid photosensitive resin is housed in the sealing solution tank 81, the base material 82 and the curing light source 83 are arranged in the sealing solution tank 81, and the movement control mechanism 85 is connected with the mold core 84 to control the movement of the mold core 84 .

[0081] Specifically, the mold core 84 is used to be made of photosensitive resin or plastic or metal material, and is arranged in the sealing solution tank filled with liquid photosensitive resin. Hydraulically attach the planar substrate on the outer surface of the mold core; or, fill the sealing solution tank with gas, and generate air pressure from top to bottom on the substrate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com