Dope used as back coat of white bottom coated white board paper and its preparing method and application

A white board paper and coating technology, applied in the direction of pigmented coating, etc., can solve the problems of low gloss of coated paper, blooming of coated paper surface, and reduced whiteness of paper, so as to achieve good surface effect and improve whiteness. degree, enhance the effect of opacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

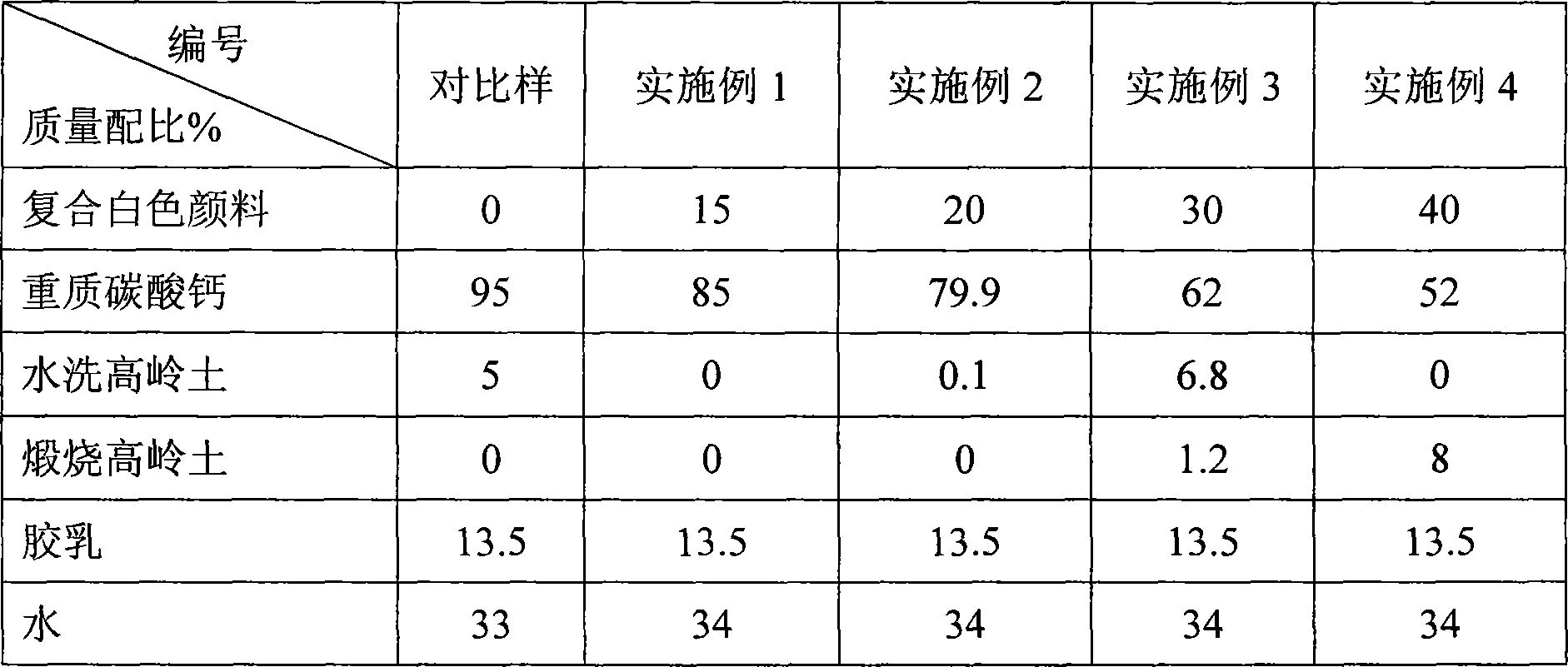

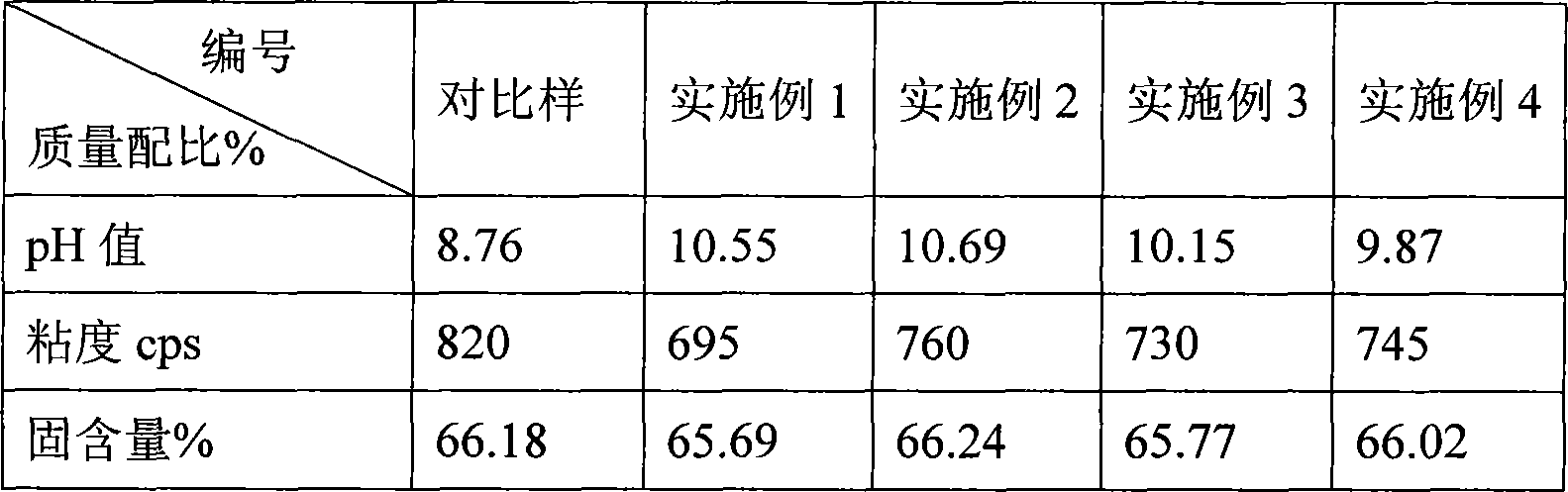

[0030] Coating Formulation

[0031]

[0032] Wherein: embodiment 1 is styrene-butadiene latex, embodiment 2 is styrene-acrylic latex, embodiment 3 is carboxyl styrene-butadiene latex, and embodiment 4 is acrylic acid latex;

[0033] The composite white pigment is prepared by the method disclosed in Chinese patent CN1935906A, wherein:

[0034] The content of the calcium carbonate shell of embodiment 1 accounts for 10% of the composite white pigment gross mass, and the thickness of the shell is 5nm;

[0035] The content of the calcium carbonate shell of embodiment 2 accounts for 90% of the composite white pigment gross mass, and the thickness of the shell is 250nm;

[0036] The content of the calcium carbonate shell of embodiment 3 accounts for 50% of the composite white pigment gross mass, and the thickness of the shell is 120nm;

[0037] The content of the calcium carbonate shell of embodiment 4 accounts for 60% of the composite white pigment gross mass, and the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com