Water-coated sand coating and preparation method thereof

A technology for sand-in-water coatings and raw materials, applied in the field of coatings, can solve the problems of poor surface effect and easily broken sand-in-water color particles, and achieve the effects of high construction tolerance, excellent pressure resistance, and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

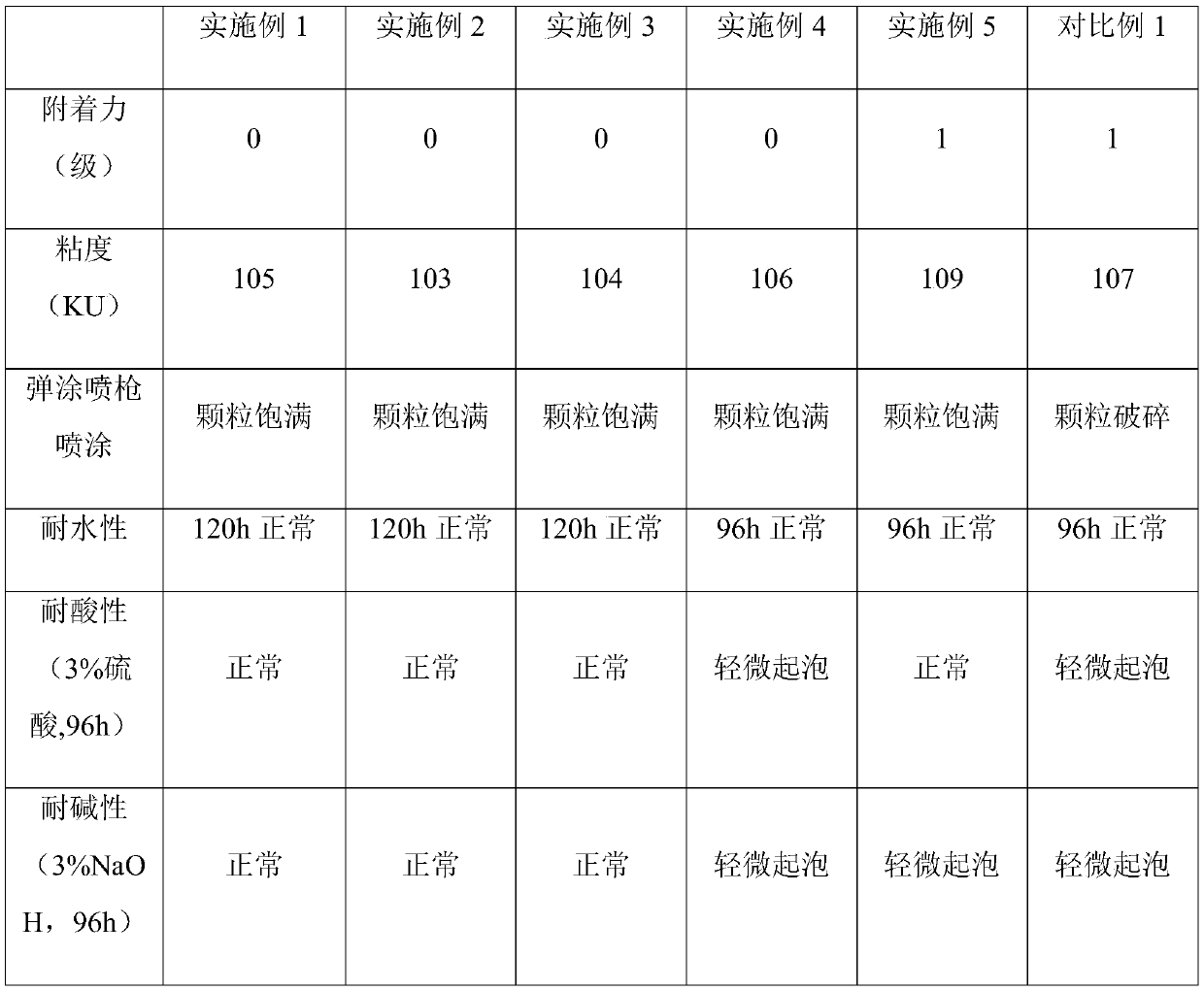

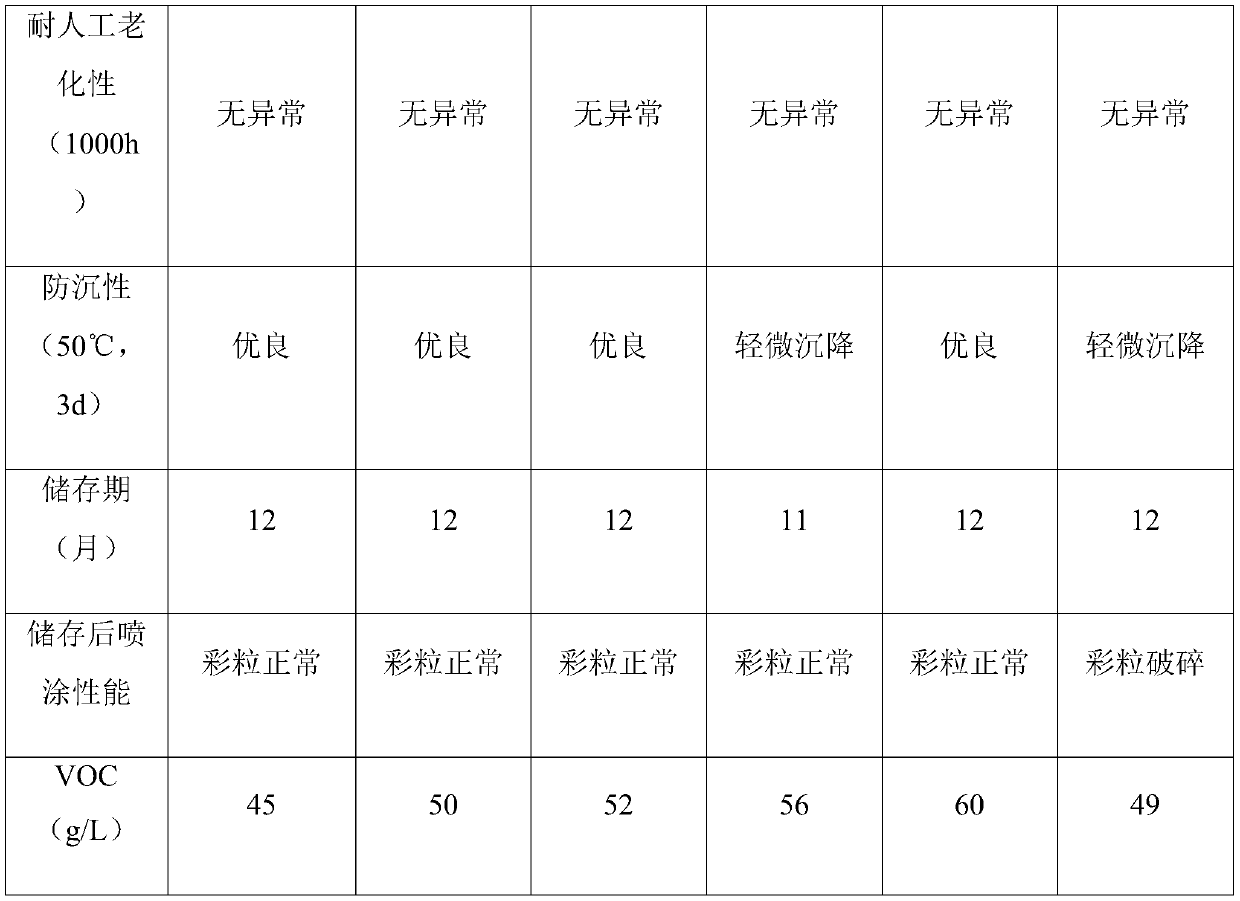

Examples

Embodiment 1

[0068] The embodiment of the present invention provides a sand-in-water coating, which includes the following raw material components in parts by mass: 23 parts of protective colloid solution, 25 parts of toning base paint, 10 parts of continuous phase emulsion and 30 parts of colored sand;

[0069] Wherein, the protective gel solution includes the following raw material components in parts by mass: 10 parts of protective rubber powder, 0.5 parts of dispersant, 2 parts of antifungal agent, 1.0 part of bactericide, 0.1 part of pH regulator and 90 parts of deionized water ;

[0070] The toning base paint includes the following raw material components in parts by mass: 30 parts of the first emulsion, 8 parts of protective colloid solution, 3 parts of associative cellulose, 0.1 part of antifungal agent, 0.8 part of dispersant, and 10 parts of filler , 0.1 part of defoamer, 0.6 part of pH regulator, 1 part of film-forming aid, 1.5 parts of antifreeze, 0.1 part of bactericide, 1 par...

Embodiment 2

[0086] The embodiment of the present invention provides a sand-in-water coating, which includes the following raw material components in parts by mass: 20 parts of protective colloid solution, 20 parts of toning base paint, 15 parts of continuous phase emulsion and 40 parts of colored sand;

[0087] Wherein, the protective gel solution includes the following raw material components in parts by mass: 3 parts of protective rubber powder, 0.1 part of dispersant, 0.1 part of antifungal agent, 2 parts of bactericide, 0.5 part of pH regulator and 80 parts of deionized water ;

[0088] The toning base paint includes the following raw material components in parts by mass: 20 parts of the first emulsion, 5 parts of protective colloid solution, 0.5 part of associative cellulose, 0.4 part of antifungal agent, 0.5 part of dispersant, and 15 parts of filler , 0.3 parts of defoamer, 0.1 part of pH regulator, 1.5 parts of film-forming aid, 0.5 part of antifreeze, 2 parts of bactericide, 0.2 ...

Embodiment 3

[0093] The embodiment of the present invention provides a sand-in-water coating, which includes the following raw material components in parts by mass: 25 parts of protective colloid solution, 23 parts of toning base paint, 13 parts of continuous phase emulsion and 35 parts of colored sand;

[0094] Wherein, the protective gel solution includes the following raw material components in parts by mass: 15 parts of protective rubber powder, 1 part of dispersant, 1 part of antifungal agent, 0.1 part of bactericide, 1 part of pH regulator and 95 parts of deionized water ;

[0095] The toning base paint includes the following raw material components in parts by mass: 45 parts of the first emulsion, 10 parts of protective colloid solution, 2 parts of associative cellulose, 0.3 parts of antifungal agent, 1 part of dispersant, and 5 parts of filler , 0.5 parts of defoamer, 0.8 parts of pH regulator, 1.2 parts of film-forming aid, 1 part of antifreeze, 1 part of fungicide, 0.5 part of anio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com