Multifunctional advertisement film preparation method

A multi-functional, film-sticking technology, applied in the field of preparation of multi-functional advertising films, can solve the problems of complex multi-layer structure, easy to fall off, poor anti-aging performance, etc., to increase the contact area, improve the adhesion strength and anti-aging performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

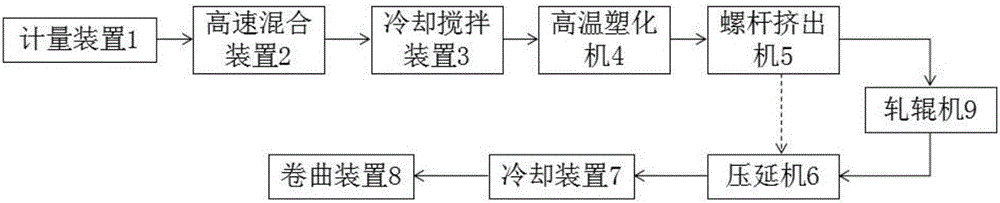

[0034] Such as figure 1 Described is a preferred process roadmap of the present invention, a preparation method of a multifunctional advertising film, comprising the following steps:

[0035] Step 1: The raw material formula includes 100 parts of PVC, 23 parts of plasticizer, 3 parts of barium-zinc composite stabilizer, 24 parts of nanofiller, 1 part of anti-UV531, 0.5 part of antioxidant CB, 1.5 parts of ACR accelerator, 0.03 parts of rutile titanium dioxide;

[0036] Step 2: Measure the above-mentioned raw material components according to the ratio through the metering device 1, and then mix and stir through the high-speed mixing device 2. The stirring speed is controlled at 500-1000 rpm, the temperature is controlled at 80-100°C, and the time is controlled at 10 -30min;

[0037] Step 3: Stir the homogeneously mixed composition in step 2 through the cooling and stirring device 3, the stirring speed is controlled at 300-500 rpm, the temperature is controlled at 30-40°C, and...

Embodiment 1

[0047] Such as figure 1 Described is a preferred process roadmap of the present invention, a preparation method of a multifunctional advertising film, comprising the following steps:

[0048] Step 1: The raw material formula includes 100 parts of PVC, 23 parts of plasticizer, 3 parts of barium-zinc composite stabilizer, 24 parts of nanofiller, 1 part of anti-UV531, 0.5 part of antioxidant CB, 1.5 parts of ACR accelerator, 0.03 parts of rutile titanium dioxide; the plasticizer is a polyester plasticizer with a molecular weight of 600-1000, and the diameter of the nanofiller is 0.1-1 μm.

[0049] Step 2: Meter the above-mentioned raw material components according to the ratio through the metering device 1, and then mix and stir through the high-speed mixing device 2. The stirring speed is controlled at 900 rpm, the temperature is controlled at 80-100°C, and the time is controlled at about 20 minutes;

[0050] Step 3: Stir the homogeneously mixed composition in step 2 through th...

Embodiment 2

[0054] Such as figure 1 Described is a preferred process roadmap of the present invention, a preparation method of a multifunctional advertising film, comprising the following steps:

[0055] Step 1: The raw material formula includes 100 parts of PVC, 15 parts of plasticizer, 3 parts of barium-zinc composite stabilizer, 20 parts of nanofiller, 1 part of anti-UV531, 0.6 part of antioxidant CB, 1 part of ACR accelerator, 0.03 parts of rutile titanium dioxide; the plasticizer is a polyester plasticizer with a molecular weight of 600-1000, and the diameter of the nanofiller is 0.1-1 μm. Polyester plasticizer is used, and its molecular weight is controlled above 600.

[0056] Step 2: Measure the above-mentioned raw material components according to the proportion through the metering device 1, and then mix and stir through the high-speed mixing device 2. The stirring speed is controlled at 900 rpm, the temperature is controlled at 80-100°C, and the time is controlled at 25 minutes;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com