Aluminizing process method for inner cavity and outer surface of cobalt-base alloy blade

A technology of cobalt-based alloy and process method, which is applied in the field of heat treatment, can solve the problems of shallow penetration layer and uncontrollable gas method, etc., and achieve the effect of improving anti-oxidation, wide application value and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

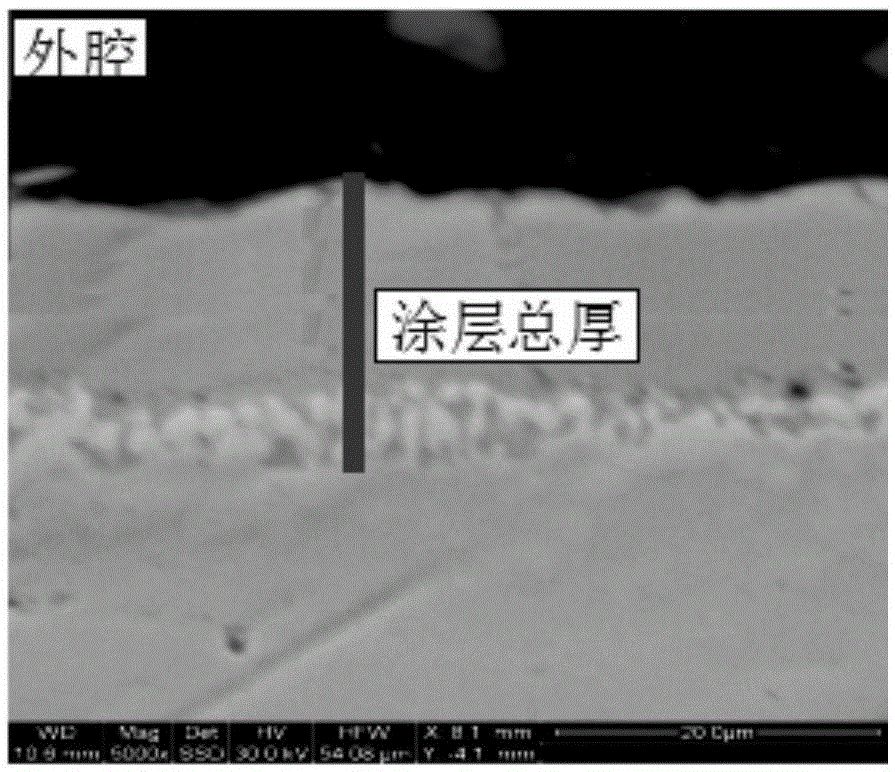

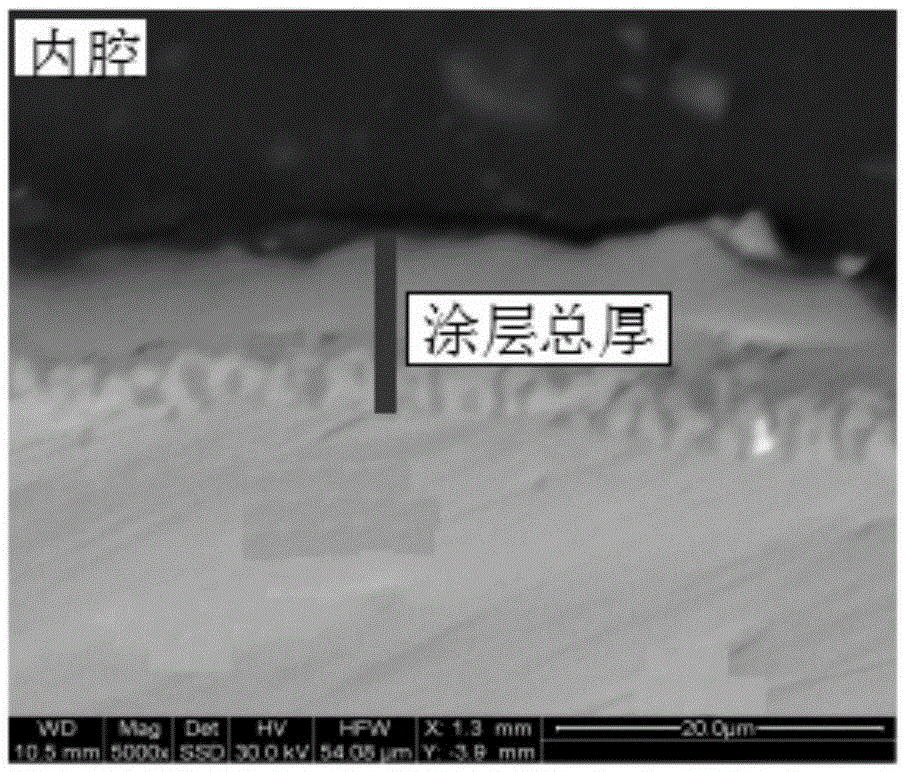

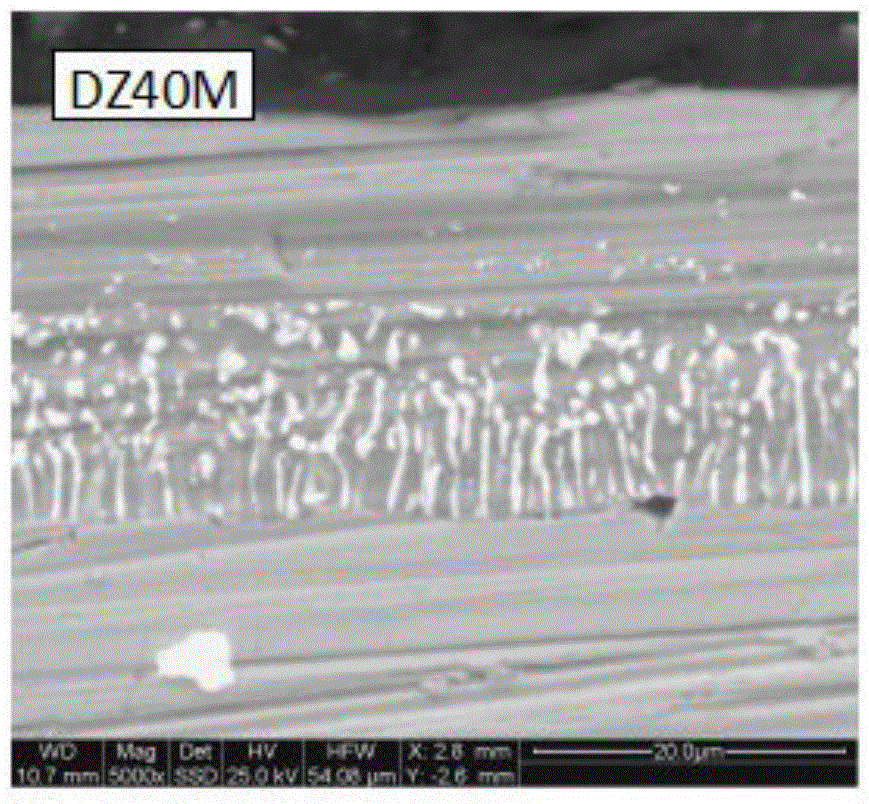

Image

Examples

Embodiment 1

[0030] In this embodiment, in order to improve the anti-oxidation and anti-corrosion properties of the blade surface, the process of aluminizing the inner cavity and outer surface of the cobalt-based alloy blade is carried out according to the following steps:

[0031] 1. Preparation of aluminum particles

[0032] Appropriate amount of aluminum particles is spread in the reactor (generating reactor outside the reaction chamber and generating reactor inside the reaction chamber).

[0033] 2. Parts preparation

[0034] (1) Use a liquid sand blasting machine to perform water blasting treatment on the parts to be deposited on the coating to remove the surface oxide layer;

[0035] (2) Put the parts in a water-based detergent solution with a mass fraction of 8%, use an ultrasonic cleaner to ultrasonically clean them for 25 minutes, rinse them with clean water, dehydrate them with absolute ethanol, and dry them with a hair dryer;

[0036] (3) Install the parts on the fixture, and ...

Embodiment 2

[0043] In this embodiment, in order to improve the anti-oxidation and anti-corrosion properties of the blade surface, the process of aluminizing the inner cavity and outer surface of the cobalt-based alloy blade is carried out according to the following steps:

[0044] 1. Preparation of aluminum particles

[0045] Appropriate amount of aluminum particles is spread in the reactor (generating reactor outside the reaction chamber and generating reactor inside the reaction chamber).

[0046] 2. Parts preparation

[0047] (1) Use a liquid sand blasting machine to perform water blasting treatment on the parts to be deposited on the coating to remove the surface oxide layer;

[0048] (2) Put the parts in a water-based cleaning agent solution with a mass fraction of 5%, use an ultrasonic cleaner to ultrasonically clean them for 20 minutes, rinse them with clean water, dehydrate them with absolute ethanol, and dry them with a hair dryer;

[0049] (3) Install the parts on the fixture....

Embodiment 3

[0056] In this embodiment, in order to improve the anti-oxidation and anti-corrosion properties of the blade surface, the process of aluminizing the inner cavity and outer surface of the cobalt-based alloy blade is carried out according to the following steps:

[0057] 1. Preparation of aluminum particles

[0058] Appropriate amount of aluminum particles is spread in the reactor (generating reactor outside the reaction chamber and generating reactor inside the reaction chamber).

[0059] 2. Parts preparation

[0060] (1) Use a liquid sand blasting machine to perform water blasting treatment on the parts to be deposited on the coating to remove the surface oxide layer;

[0061] (2) Put the parts in a water-based cleaning agent solution with a mass fraction of 10%, use an ultrasonic cleaner to ultrasonically clean them for 30 minutes, rinse them with clean water, dehydrate them with absolute ethanol, and dry them with a hair dryer;

[0062] (3) Install the parts on the fixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com