A protective method of gh4708 nickel-based superalloy anti-high temperature wear-resistant coating

A nickel-based superalloy and wear-resistant coating technology, which is applied in the field of heat treatment, can solve problems such as complex processes, and achieve the effects of improving oxidation resistance and wear resistance, and improving oxidation resistance and corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

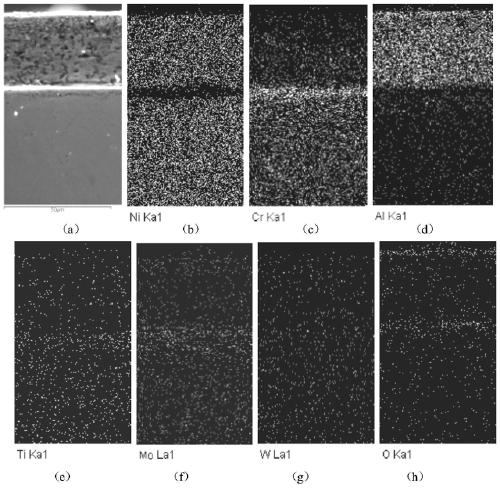

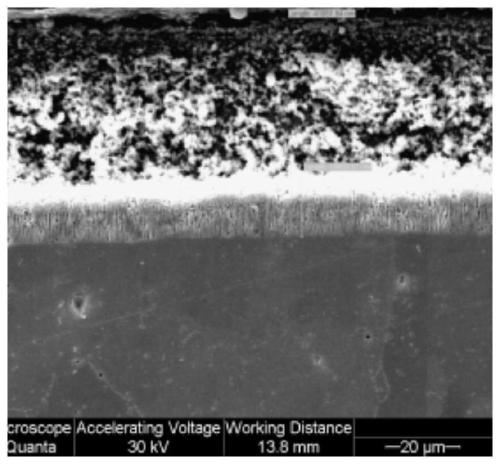

Embodiment 1

[0030] In this embodiment, the protection method of GH4708 nickel-based superalloy anti-high temperature and wear-resistant coating, the specific steps are as follows:

[0031] (1) Material: GH4708, the composition is shown in Table 1. Before aluminizing, it is subjected to 1140°C×1h, air-cooled for solid solution, and after aluminizing, it is subjected to 800°C×15h, and air-cooled for aging.

[0032] Table 1 GH4708 chemical composition (wt%)

[0033]

[0034] (2) Aluminized

[0035] Aluminizing agent configuration: Aluminizing agent is prepared by mixing aluminum-iron alloy powder with iron content of 42wt% and ammonium chloride powder of GB658-1988. Among them, by weight percentage, the aluminum-iron alloy powder accounts for 99.0%, and the ammonium chloride powder accounts for 1.0%.

[0036] Infiltration agent roasting: When roasting aluminum-iron alloy powder, add dry ammonium chloride powder and mix well. Put the mixture into an aluminized bag and keep it warm at 95...

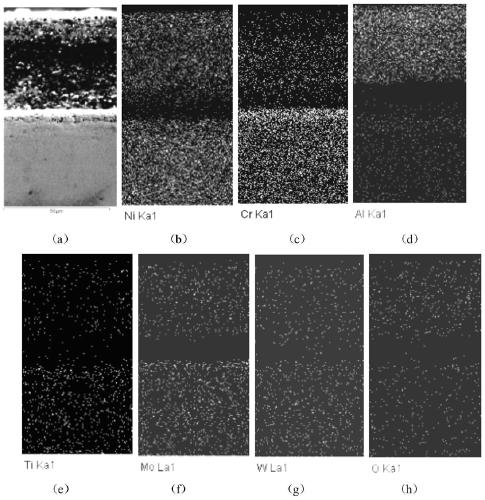

Embodiment 2

[0052] The difference from Example 1 is that in this example, the specific steps for the protection method of the GH4708 nickel-based superalloy anti-high temperature and wear-resistant coating are as follows:

[0053] (1) Material: GH4708, the composition is shown in Table 1. Before aluminizing, it is subjected to 1140°C×1h, air-cooled for solid solution, and after aluminizing, it is subjected to 800°C×15h, and air-cooled for aging.

[0054] (2) Aluminized

[0055] Aluminizing agent configuration: Aluminizing agent is made by mixing aluminum-iron alloy powder with iron content of 50wt% and ammonium chloride powder of GB658-1988. Among them, by weight percentage, the aluminum-iron alloy powder accounts for 98.5%, and the ammonium chloride powder accounts for 1.5%.

[0056] Infiltration agent roasting: When roasting aluminum-iron alloy powder, add dry ammonium chloride powder and mix well. Put the mixture into an aluminized bag and keep it warm at 950°C±20°C for 5h-10h.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com