Build-up wear-resistant copper alloy and valve seat

一种耐磨铜、气门座的技术,应用在金属材料涂层工艺、机器/发动机、机械设备等方向,能够解决抗裂性变差、焊缝裂纹等问题,达到改善堆焊性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] (1) In boron-containing alloys, when they come into contact with air in a molten state, they generate boron oxide (B 2 o 3 ). The B 2 o 3 Acts as a flux to improve the fluidity and weldability of wear-resistant copper alloys for overlay welding to the substrate.

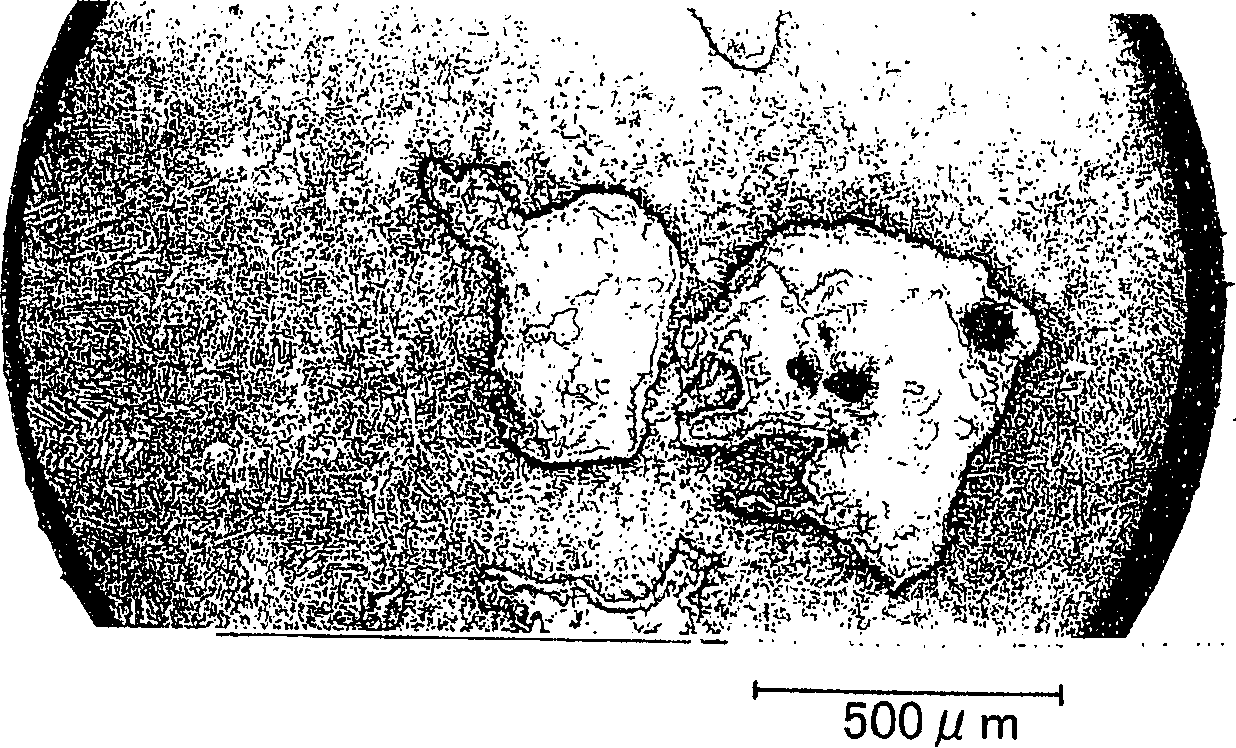

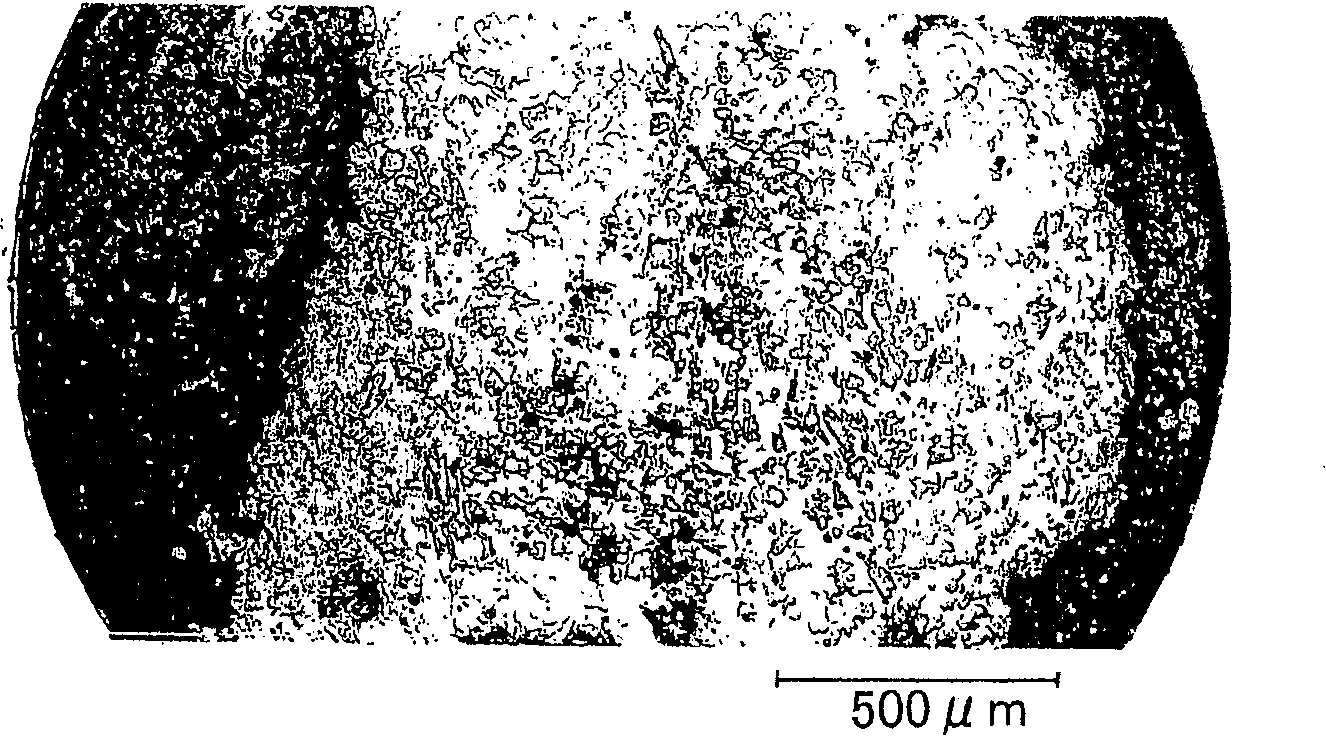

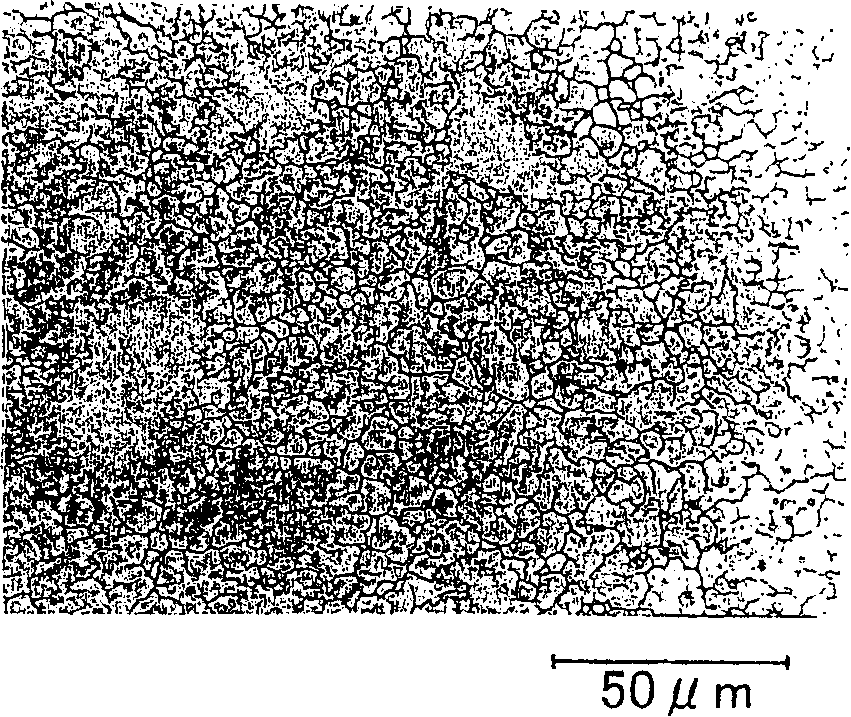

[0043]The metal structure of the wear-resistant alloy for overlay welding according to the present invention is such that hard particles are distributed in a soft matrix. If only boron is added to the copper alloy, coarse, very hard and brittle borides of nickel, iron and molybdenum will be formed in the hard particles or matrix. Therefore, the hard particles become prone to cracking and lead to poor crack resistance during build-up welding. Furthermore, due to these coarse and very hard borides, although the amount of wear of the copper alloy itself is small, the mating parts are worn rougher and thus increase the so-called damage to the mating parts. On the contrary, by compositely adding chromium whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com