Composite oil displacement agent and preparation method and application thereof

A technology of composite oil flooding and active agent, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems of high cost, poor formation adaptability, formation adsorption, etc., to reduce tension and improve crude oil. The effect of high recovery factor, surface/interfacial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

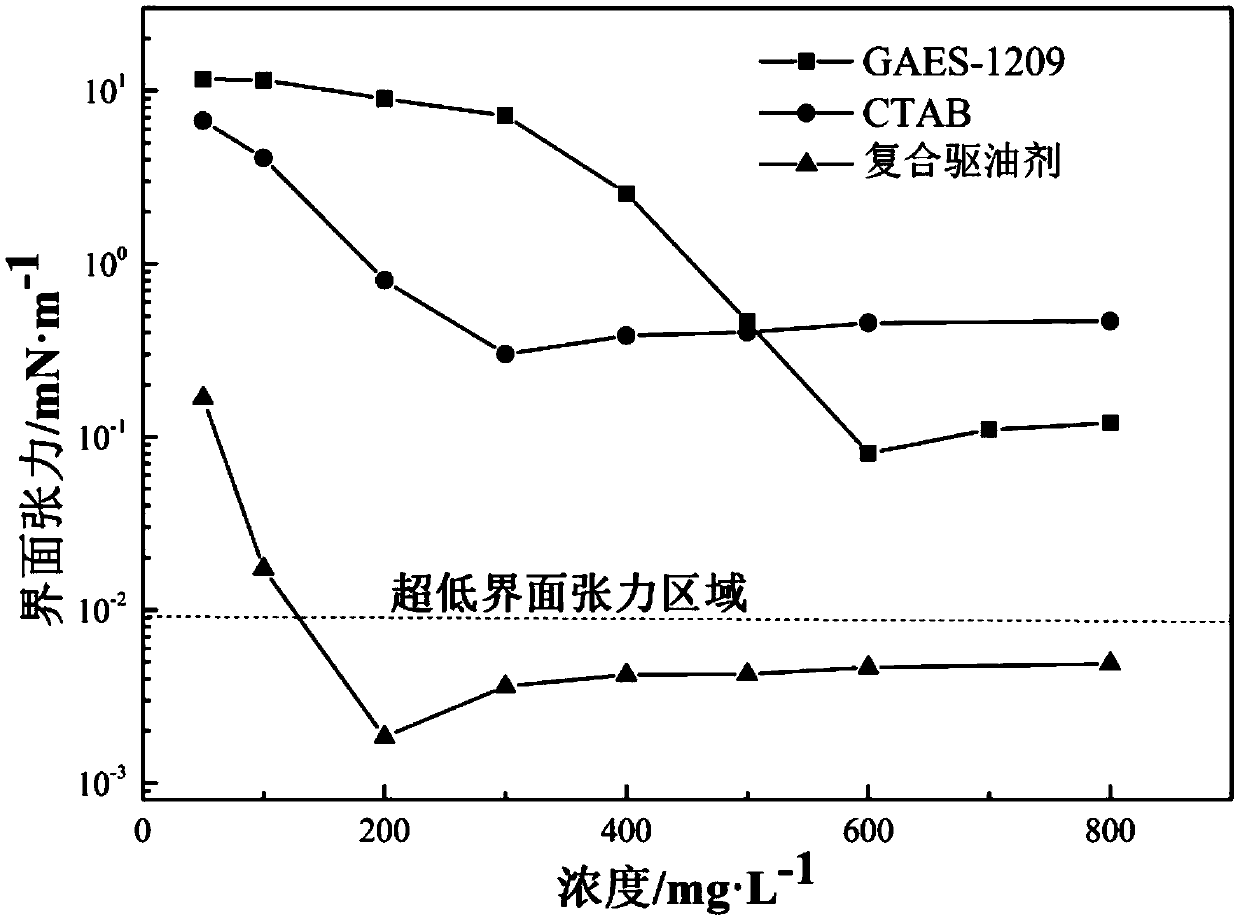

[0038] This embodiment provides a composite oil displacement agent. The surfactant in the composite oil displacement agent is composed of A: GAES-1209 and B: cetyltrimethylammonium bromide (CTAB). The molar ratio of A and B is 0.25. By adding the actual formation water in the oilfield to prepare composite oil displacement agents with different total surfactant concentrations (50-800mg / L), the oil displacement test was carried out.

[0039] The instrument uses TX-500C interfacial tension meter, the oil phase is degassed and dehydrated crude oil from an oil field, the test temperature is 45°C, and the oil-water interfacial tension is measured under the condition of 5000 rpm. The experimental results are as follows figure 1 shown. figure 1 It is the change curve of oil / water interfacial tension with the total concentration of surfactant (the square is the single GAES-1209 system, the circle is the cetyltrimethylammonium bromide system, and the triangle is the composite oil displ...

Embodiment 2

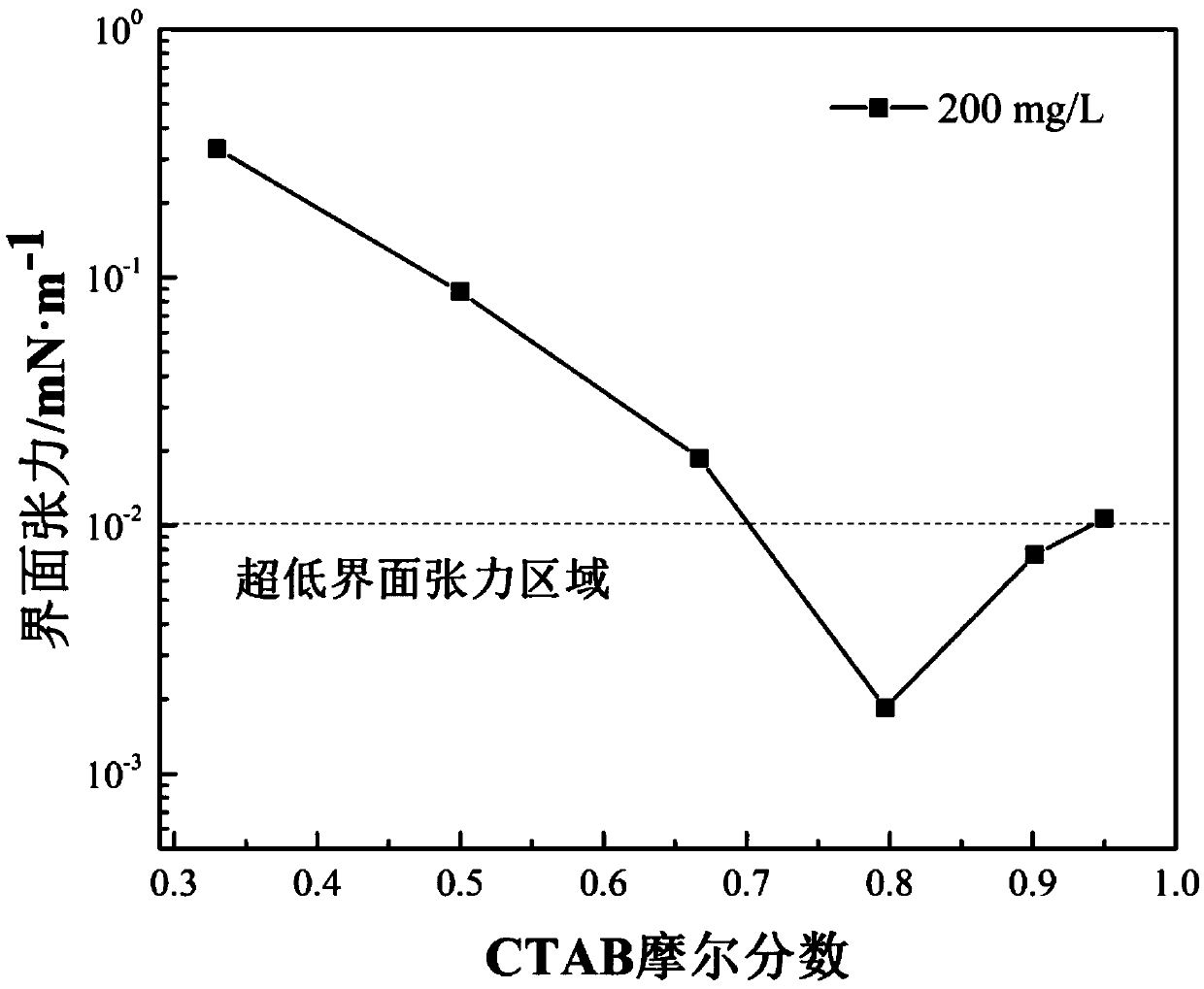

[0042] This embodiment provides a composite oil displacement agent. The surfactant in the composite oil displacement agent is composed of A: GAES-1209 and B: cetyltrimethylammonium bromide. A composite oil displacement agent with a total surfactant concentration of 200mg / L was prepared by adding the actual formation water in the oil field, and the molar ratio of A and B was changed, and the oil displacement test was carried out.

[0043] The instrument uses TX-500C interfacial tension meter, the oil phase is degassed and dehydrated crude oil from an oil field, the test temperature is 45°C, and the oil-water interfacial tension is measured under the condition of 5000 rpm. The experimental results are as follows figure 2 shown. figure 2 It is the change curve of oil / water interfacial tension with the mole fraction of cationic surfactant.

[0044] Depend on figure 2 It can be seen that the optimal molar fraction of CTAB is 0.8, that is, when the compounding ratio of GAES-120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com