Segmented variable-coefficient iron loss model for fine analysis of loss of alternating-current motor

An AC motor, refined technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Taking silicon steel sheet DR510 and silicon steel sheet DW470 as examples, according to the model shown in formula (5), using the loss coefficients shown in formulas (6) to (11) to solve the loss coefficients, the loss coefficient solution results are as follows Figure 1-Figure 4 shown. From figure 2 and Figure 4 It can be seen that for different types of silicon steel sheets, the additional magnetic density term coefficients of eddy current loss and hysteresis loss are very different; therefore, the loss coefficients for different types of silicon steel sheets need to be solved separately. In addition, in most cases β 1 <0, that is to say, the additional magnetic density item of hysteresis loss decreases gradually, indicating that hysteresis loss decreases with the increase of saturation degree of ferromagnetic material.

Embodiment 2

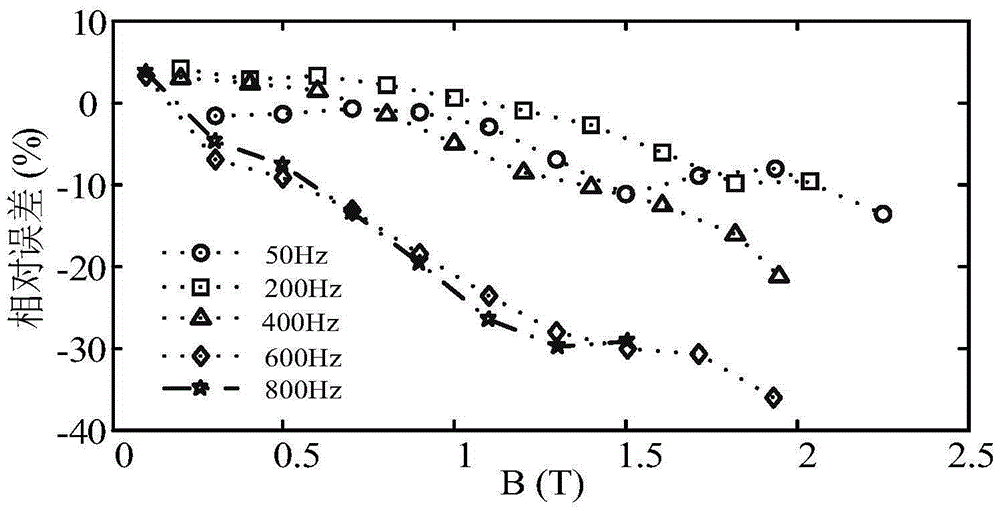

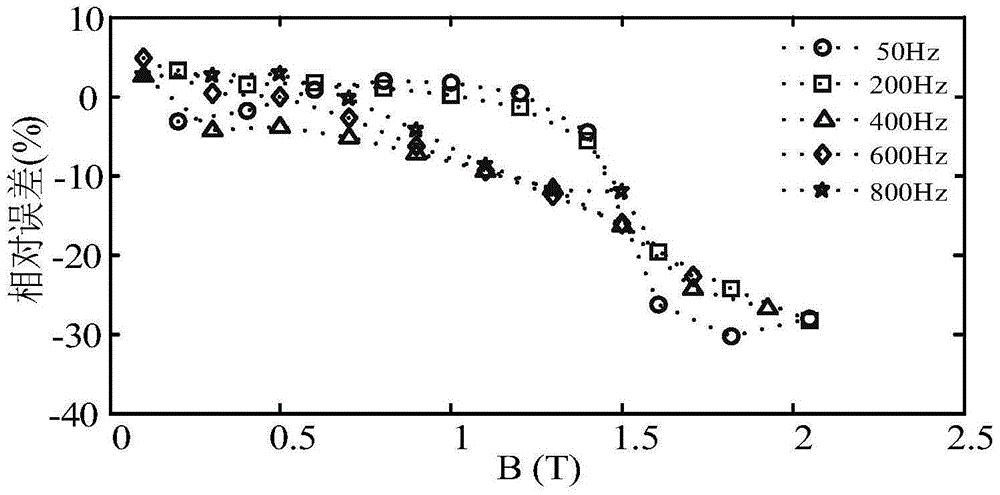

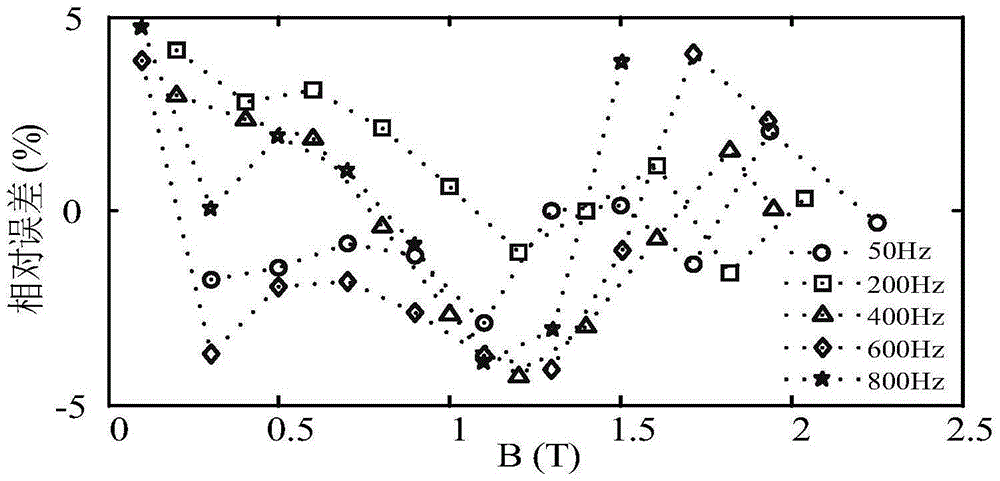

[0071] Comparing the loss value calculated by the Bertotti trinomial model and the model shown in formula (5) with the measured value, the relative error results are as follows Figure 1 ~ Figure 4 As shown, it can be seen that the Bertotti trinomial constant coefficient model has a high calculation accuracy when the magnetic flux density B≤1.2T and the frequency ffigure 1 and figure 2 The error shown in can exceed 40%; And according to the calculation error of the proposed model of the present invention is generally within 5%, such as image 3 shown.

Embodiment 3

[0073] Taking silicon steel sheet DR510 as an example, compare the calculated and measured loss values under different frequency and magnetic density conditions, the results are as follows Figure 5 shown. in, Figure 5 (a) is 50Hz, under different flux density conditions, the Bertotti trinomial constant coefficient model, the model of the present invention and the measured value contrast; Figure 5 (b) is 100Hz, under different flux density conditions, the Bertotti trinomial constant coefficient model, the model of the present invention and the measured value contrast; Figure 5 (c) is 400Hz, under different magnetic density conditions, the Bertotti trinomial constant coefficient model, the model of the present invention and the measured value contrast; Figure 5 (d) is 600Hz, under different magnetic density conditions, Bertotti trinomial constant coefficient model, the present invention's model and measured value contrast; Can find out, the model of the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com