Giant magnetoresistance current sensor

A technology of current sensor and giant magnetoresistance, which is applied in the direction of measuring current/voltage, instruments, measuring electric variables, etc., can solve the problems that cannot completely eliminate temperature drift, zero drift, interference, etc., and achieve the reduction of influence, suppression of temperature drift and Zero drift, beneficial to the effect of linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

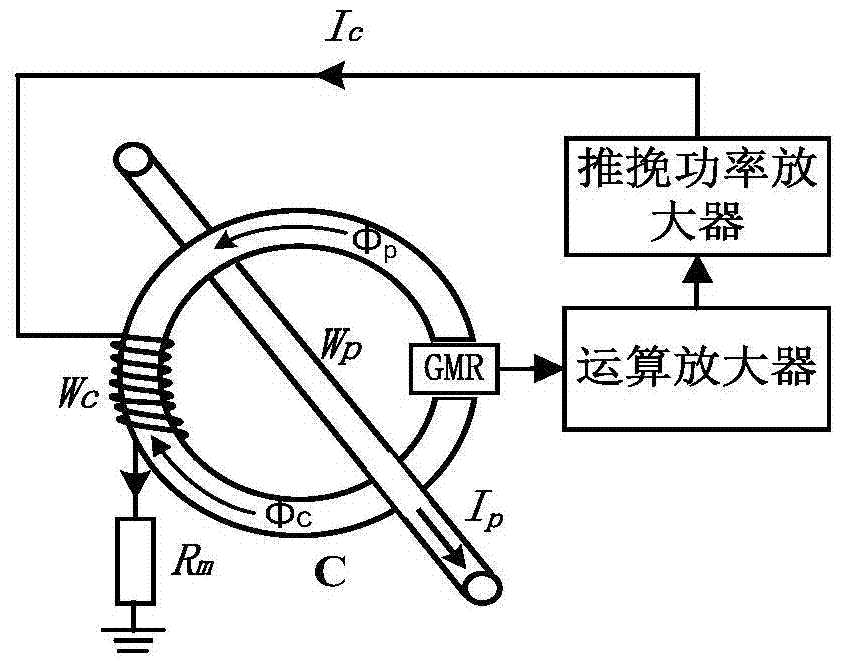

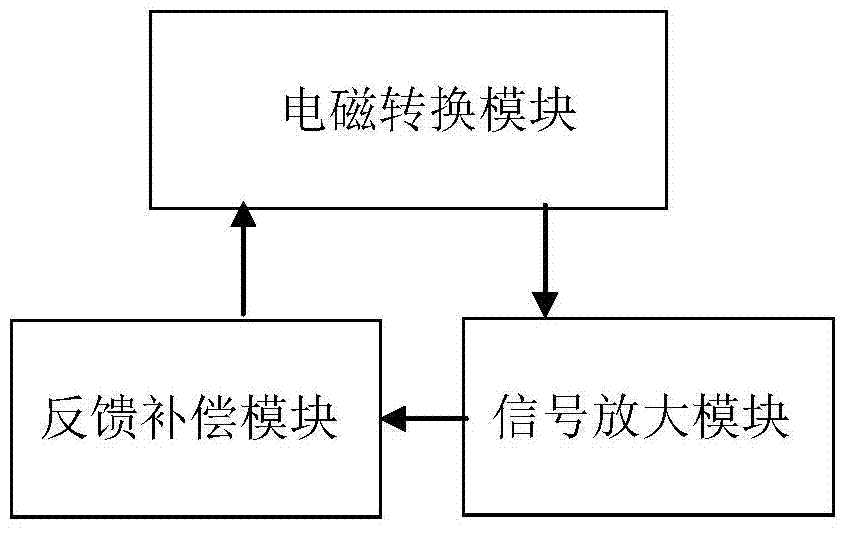

[0037] The giant magnetoresistive current sensor of the present embodiment is made up of electromagnetic conversion module, signal amplification module and feedback compensation module three parts, and wherein, the number of turns is the primary side winding Wp of 1 turn to pass through magnetic core C of magnetic gathering ring, and number of turns is The 120-turn feedback winding Wc is wound on the magnetic core C of the magnetic gathering ring. One end of the feedback winding Wc is connected to a push-pull power amplifier of the model L165, and the other end of the feedback winding Wc is connected to a sampling resistor Rm. The magnetic ring core C and the feedback winding Wc form a closed-loop system measurement probe. After gathering the magnetic field generated by the primary current Ip, the magnetic ring core C acts on the giant magnetoresistance chip GMR, and the giant magnetoresistance chip GMR is in the After feeling the effect of the magnetic field, there will be a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com