Patents

Literature

32 results about "Barkhausen effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

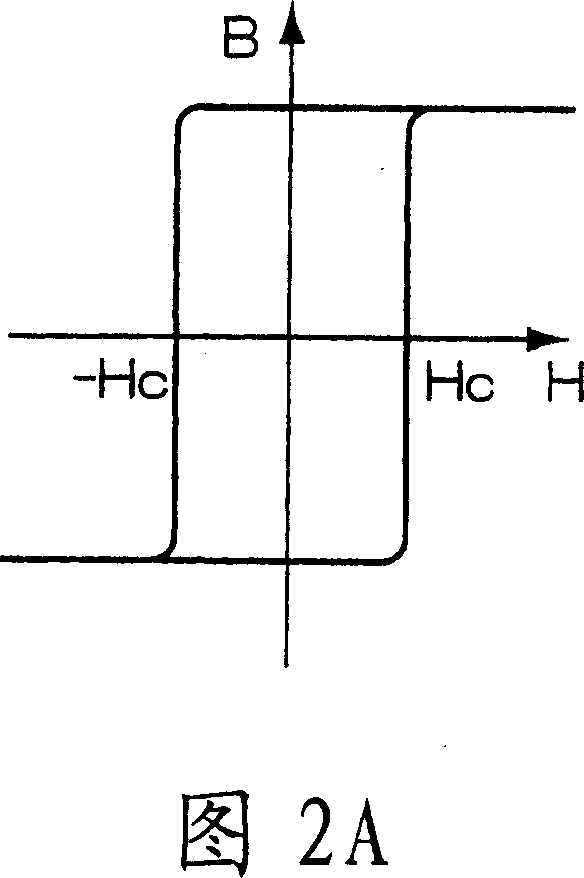

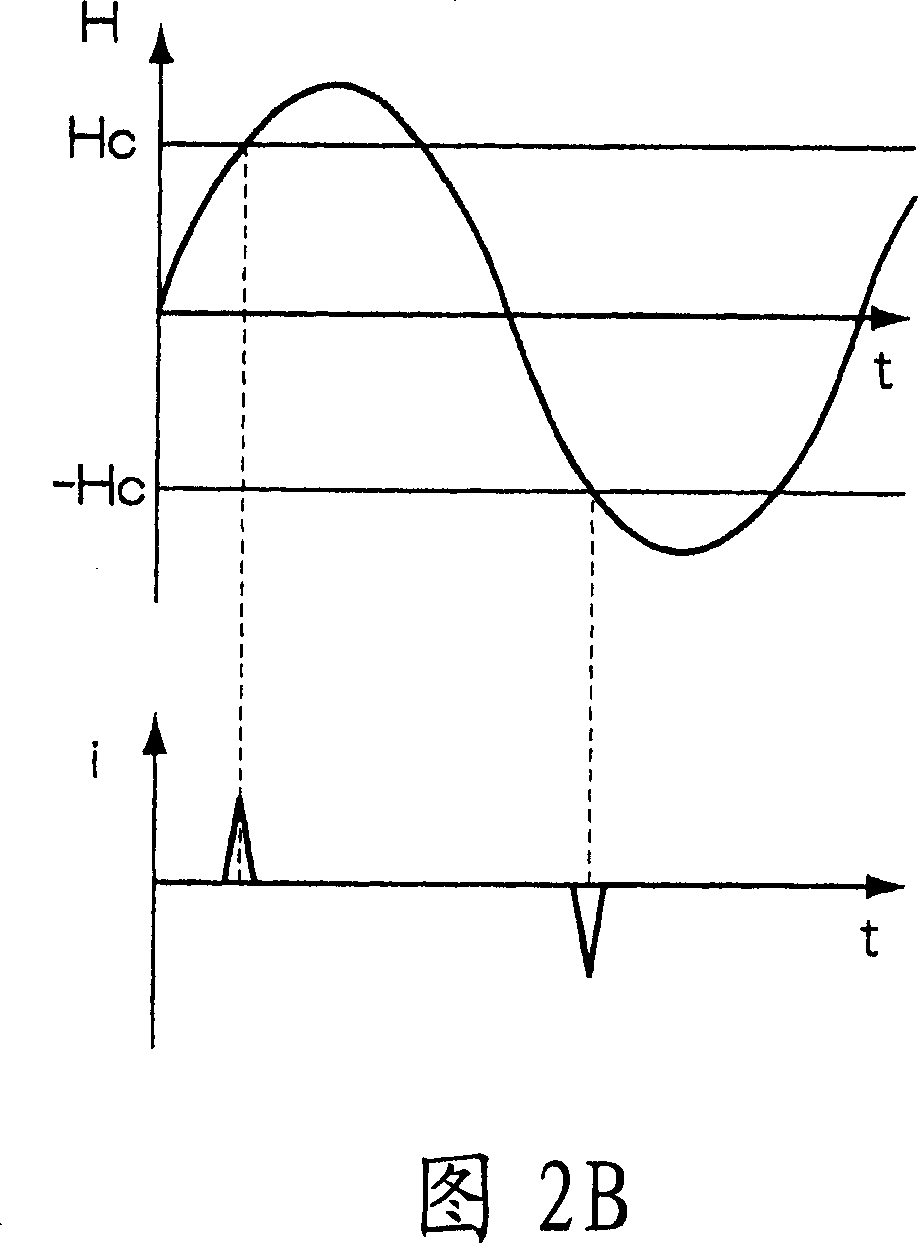

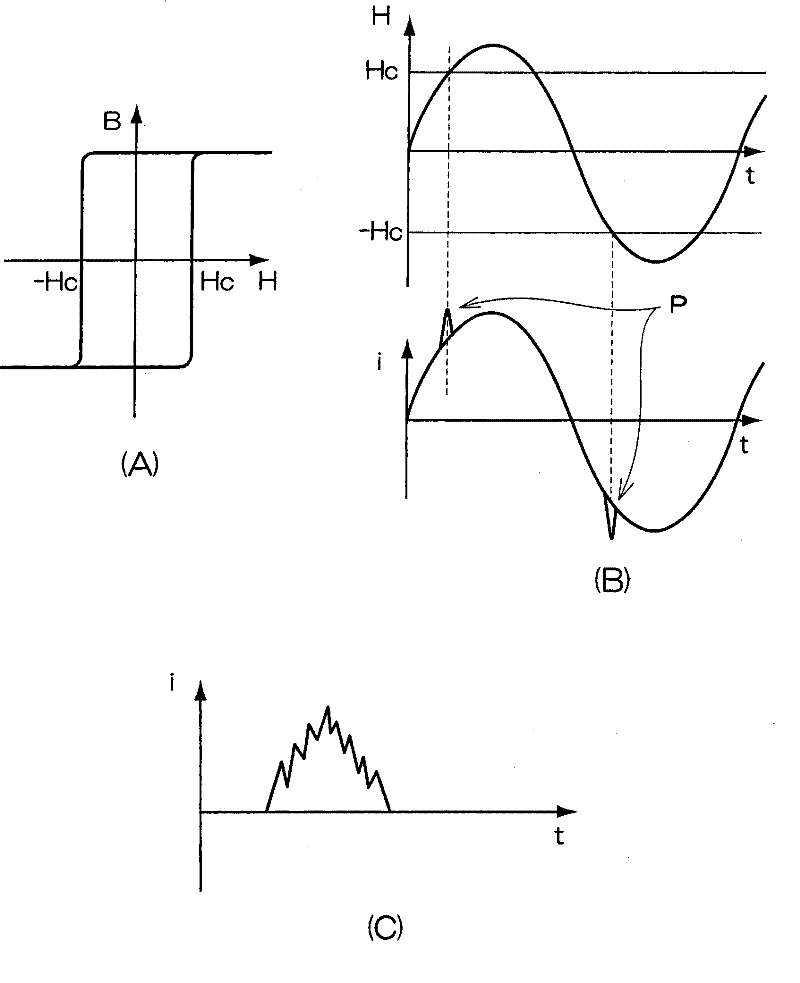

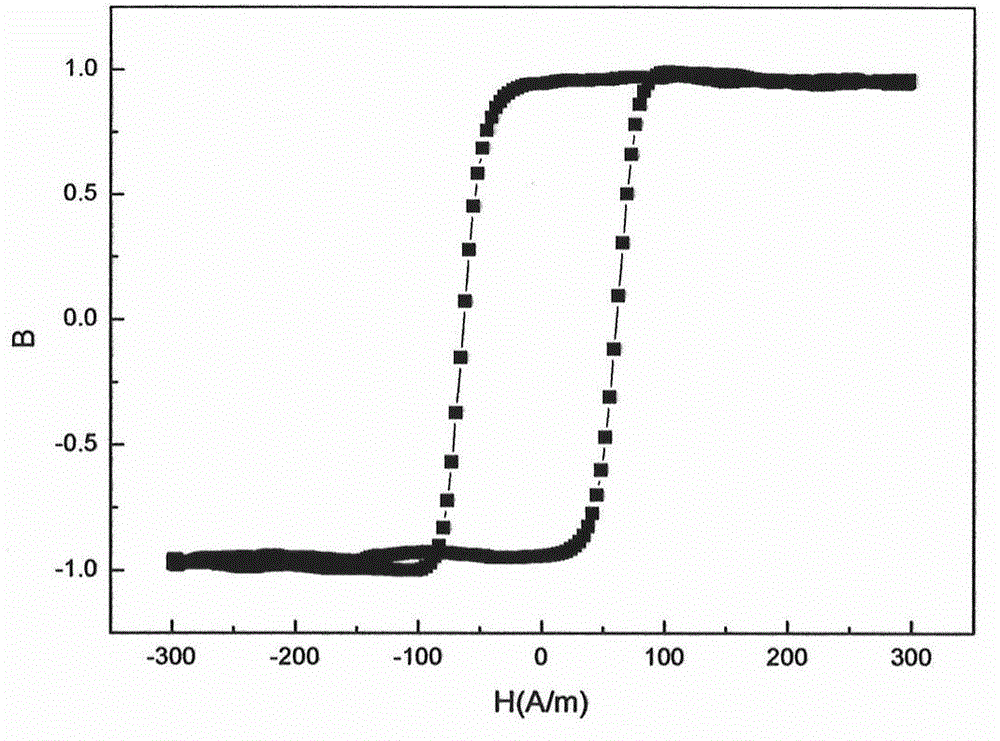

The Barkhausen effect is a name given to the noise in the magnetic output of a ferromagnet when the magnetizing force applied to it is changed. Discovered by German physicist Heinrich Barkhausen in 1919, it is caused by rapid changes of size of magnetic domains (similarly magnetically oriented atoms in ferromagnetic materials).

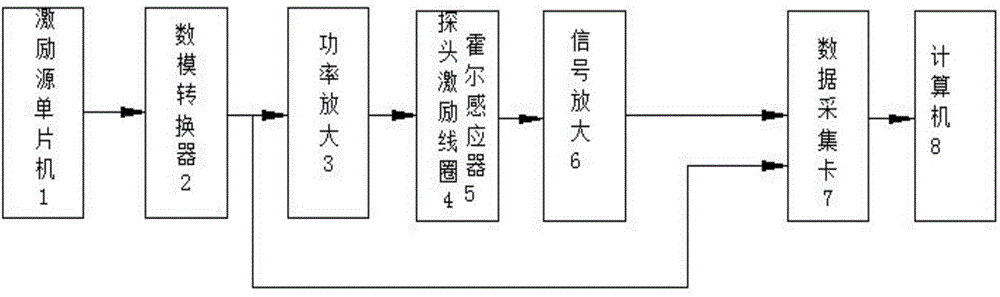

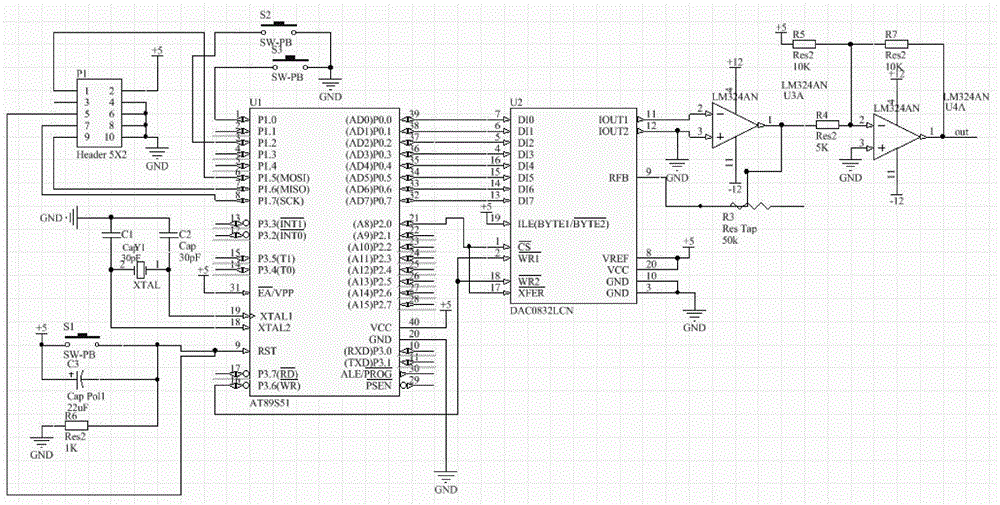

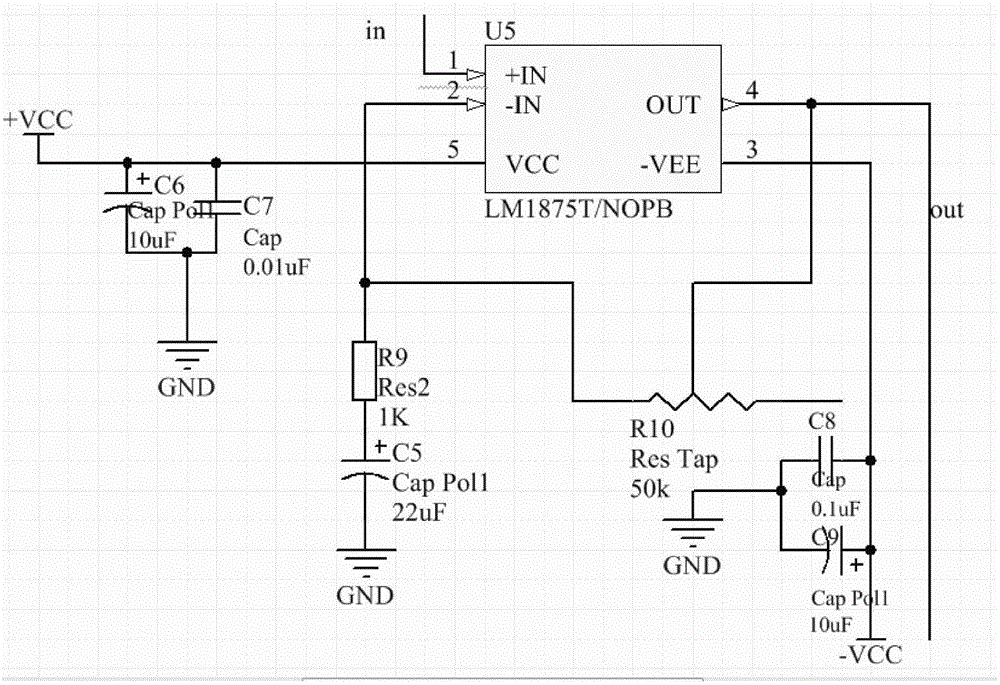

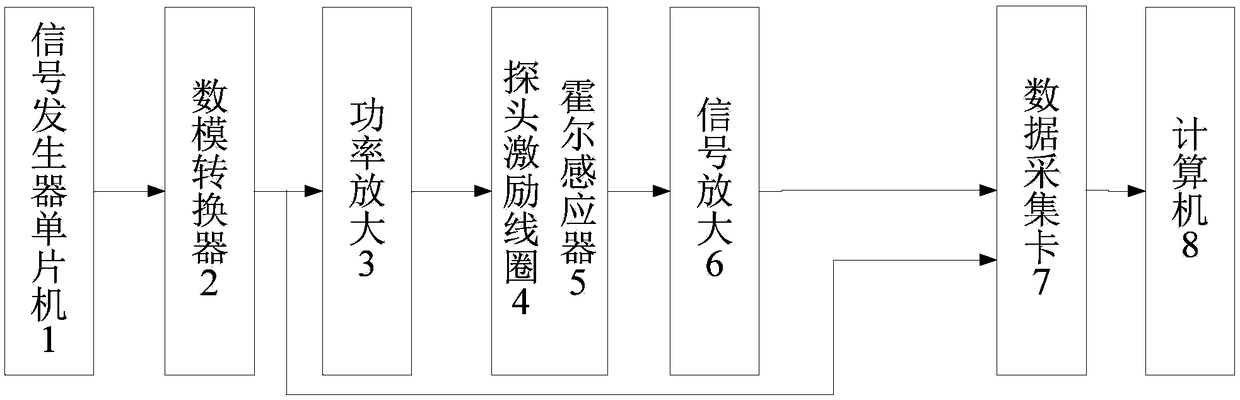

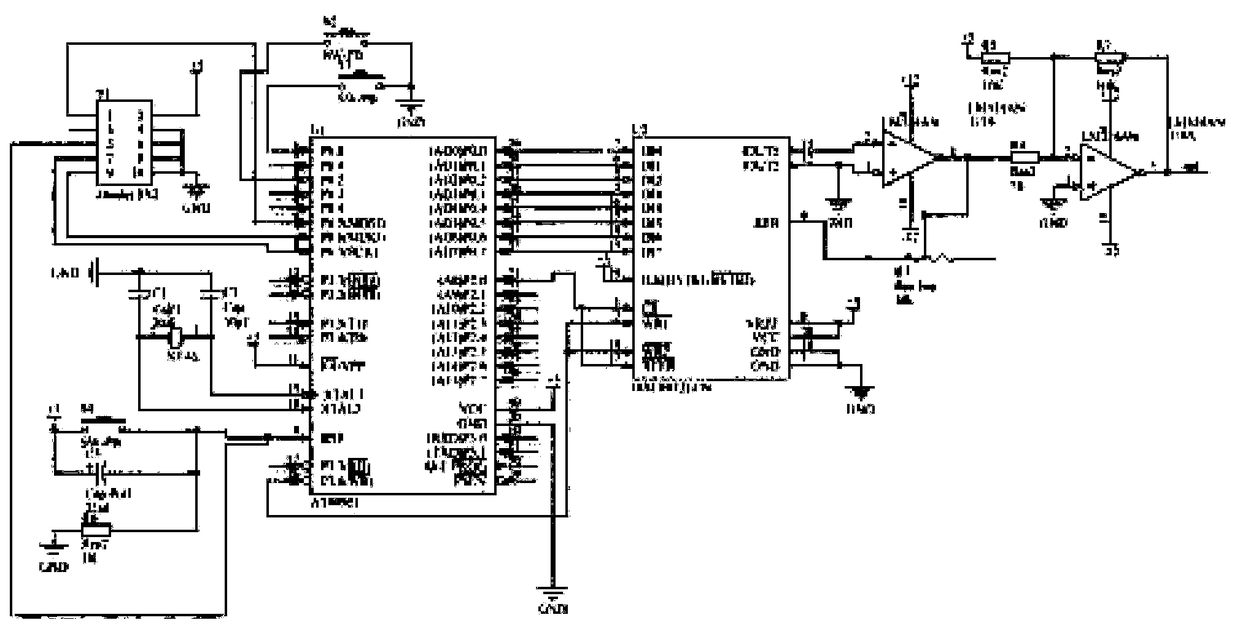

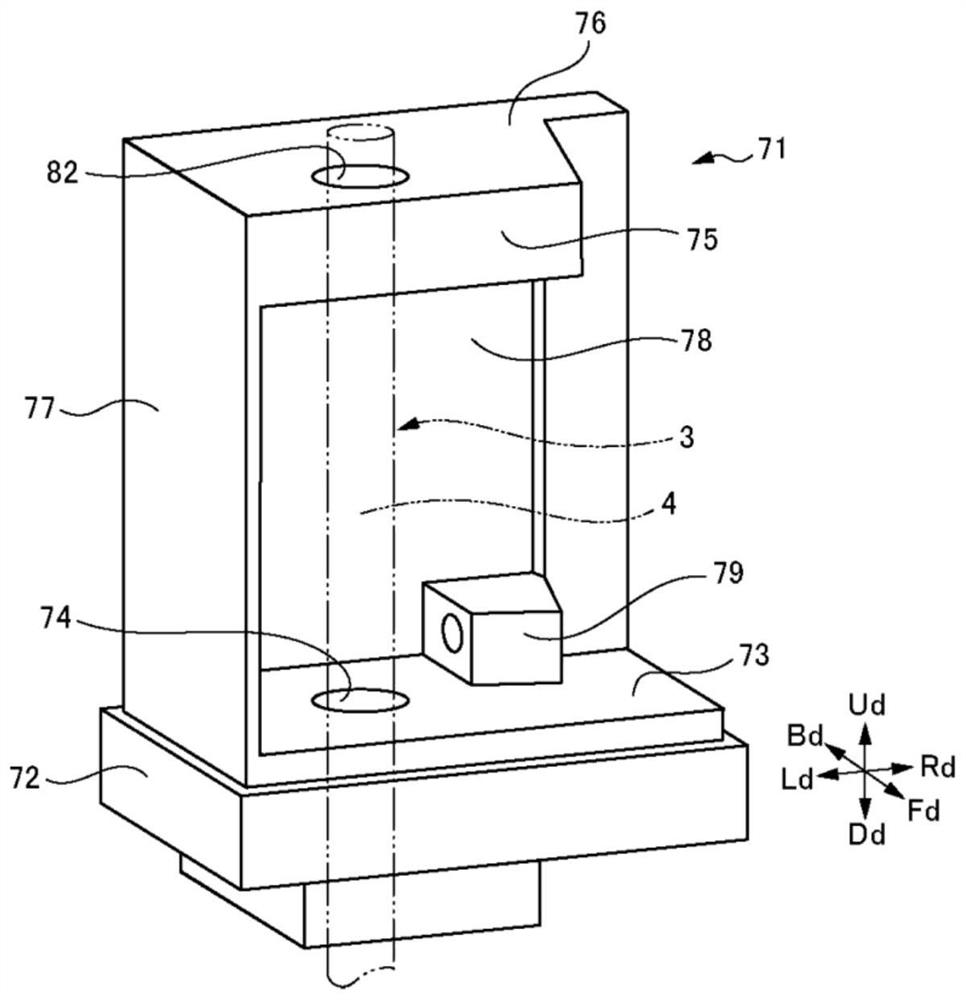

Defect and stress non-destructive testing system and non-destructive testing method based on pulsed eddy current and Barkhausen

ActiveCN104977352AMixed Signal Simple and EffectiveReliable detection methodMaterial magnetic variablesData acquisitionFerromagnetism

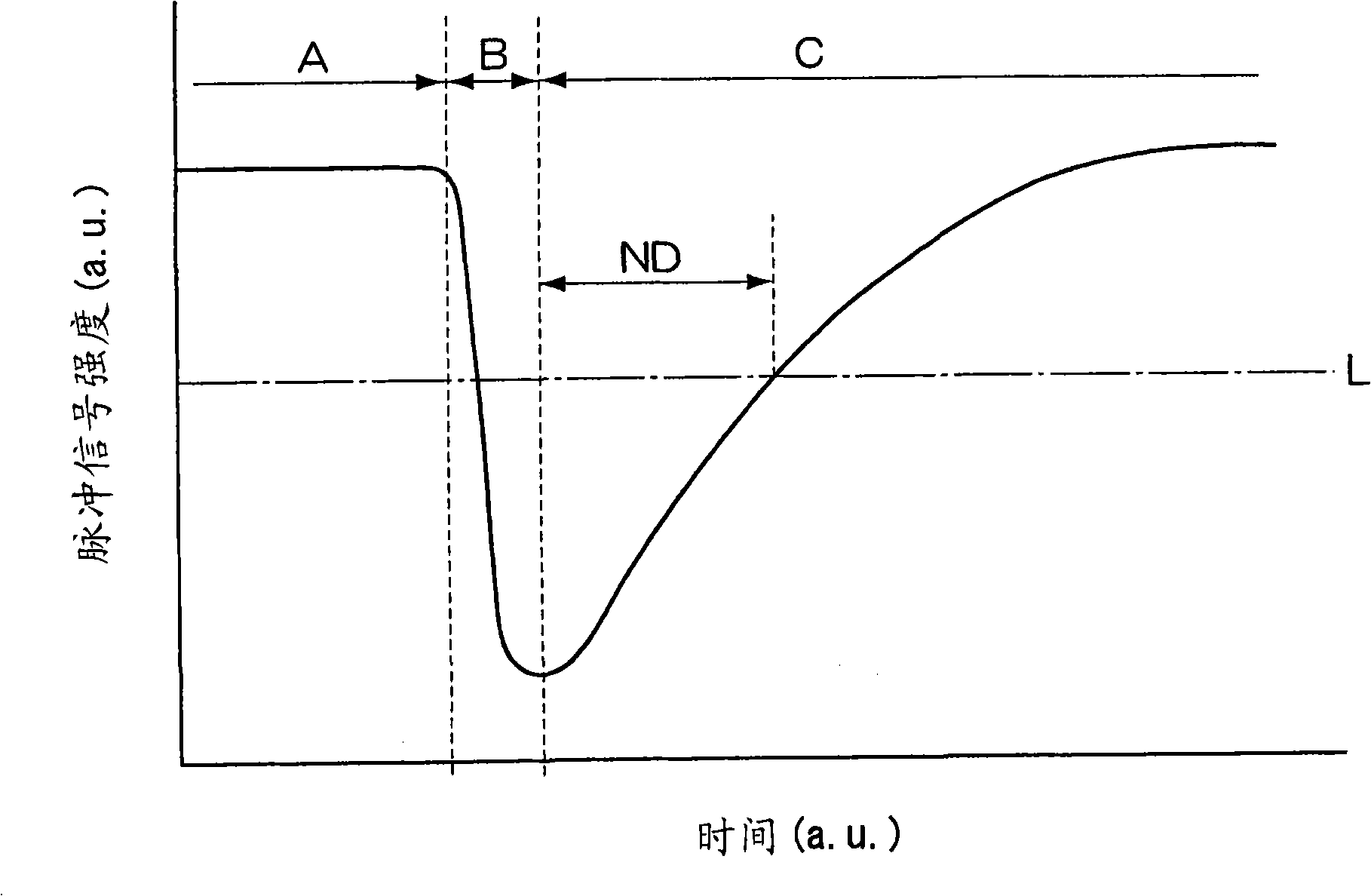

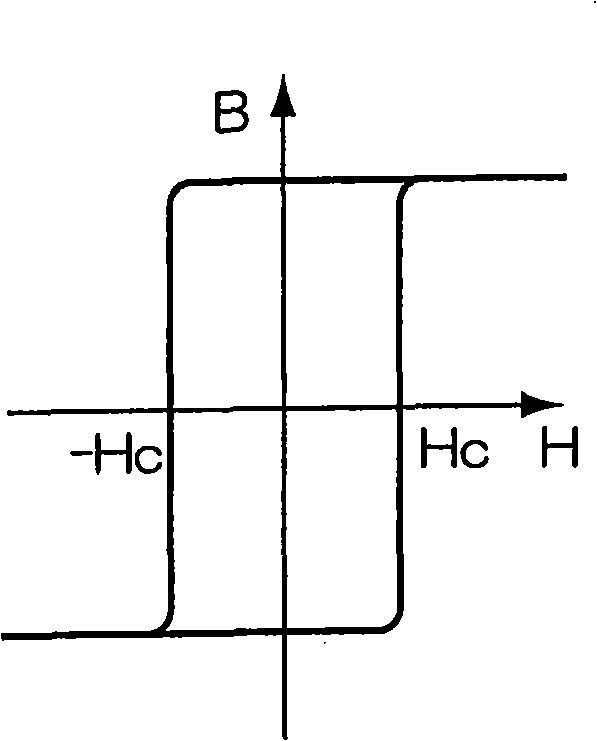

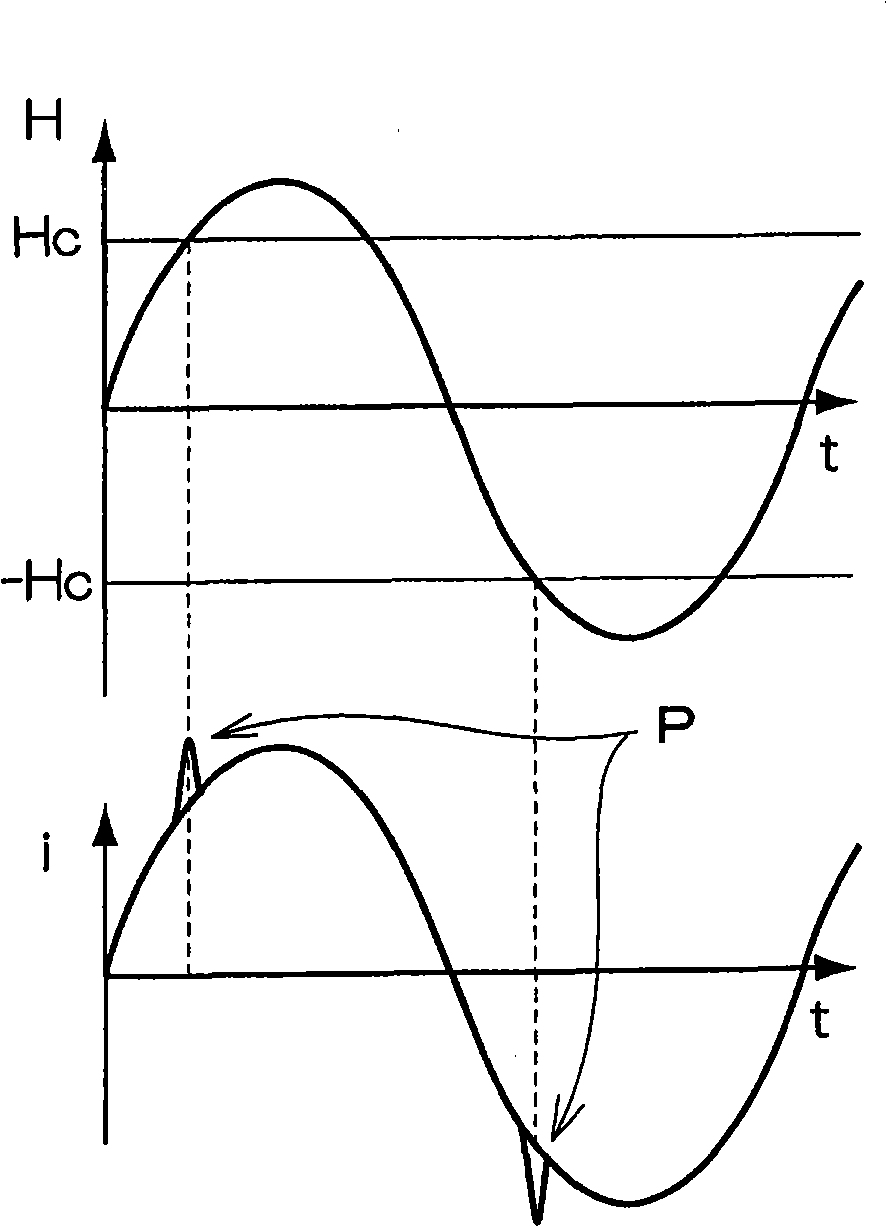

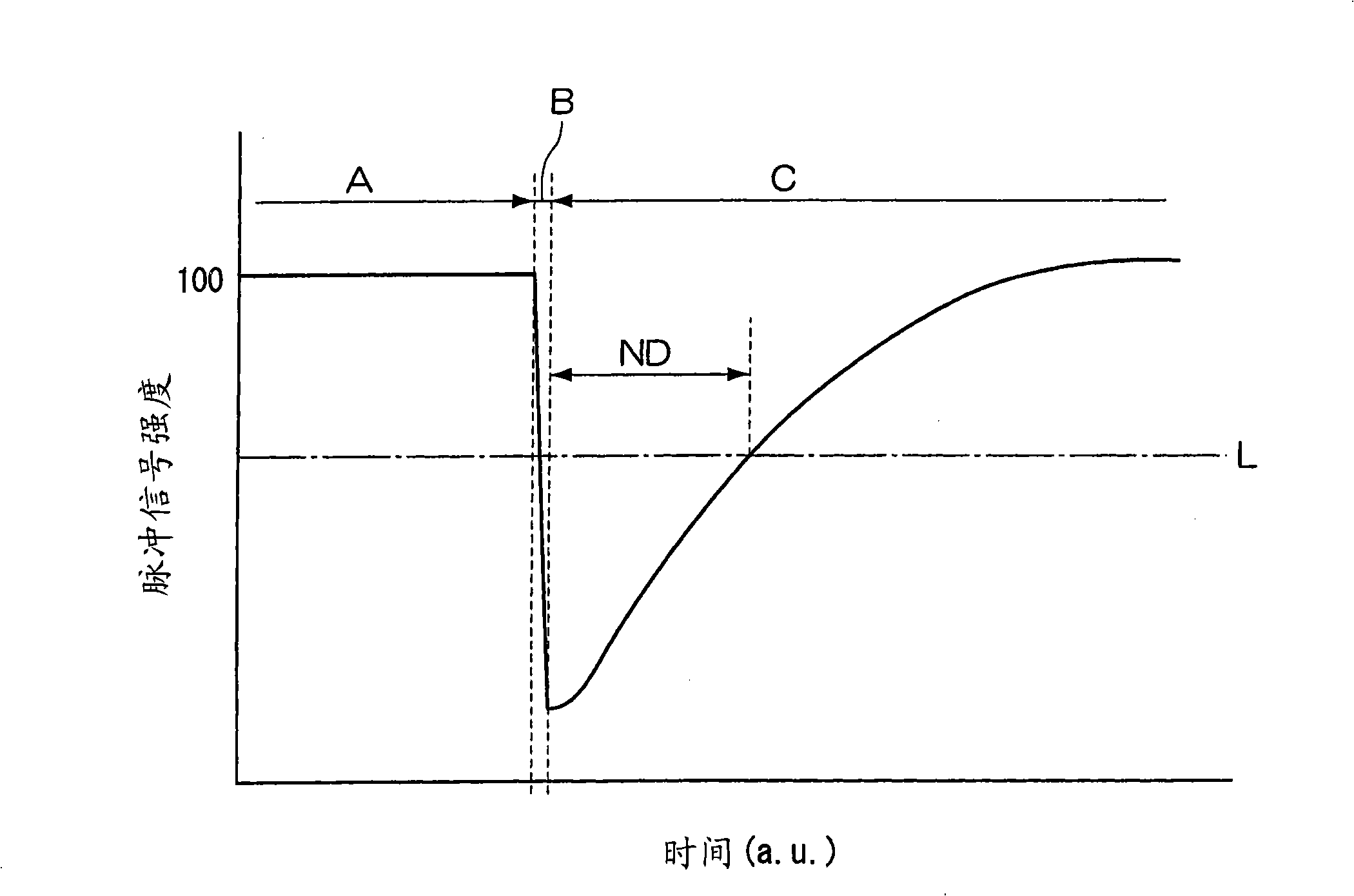

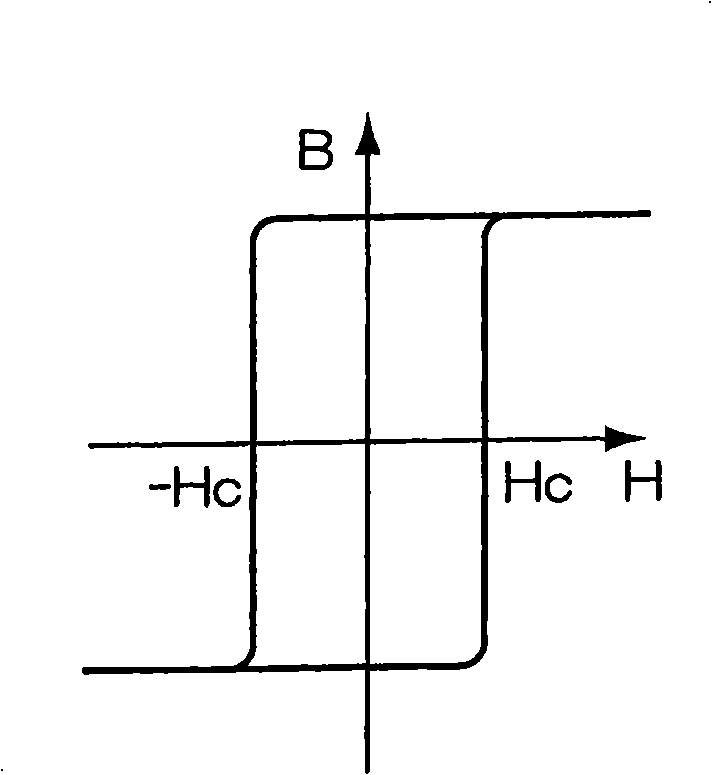

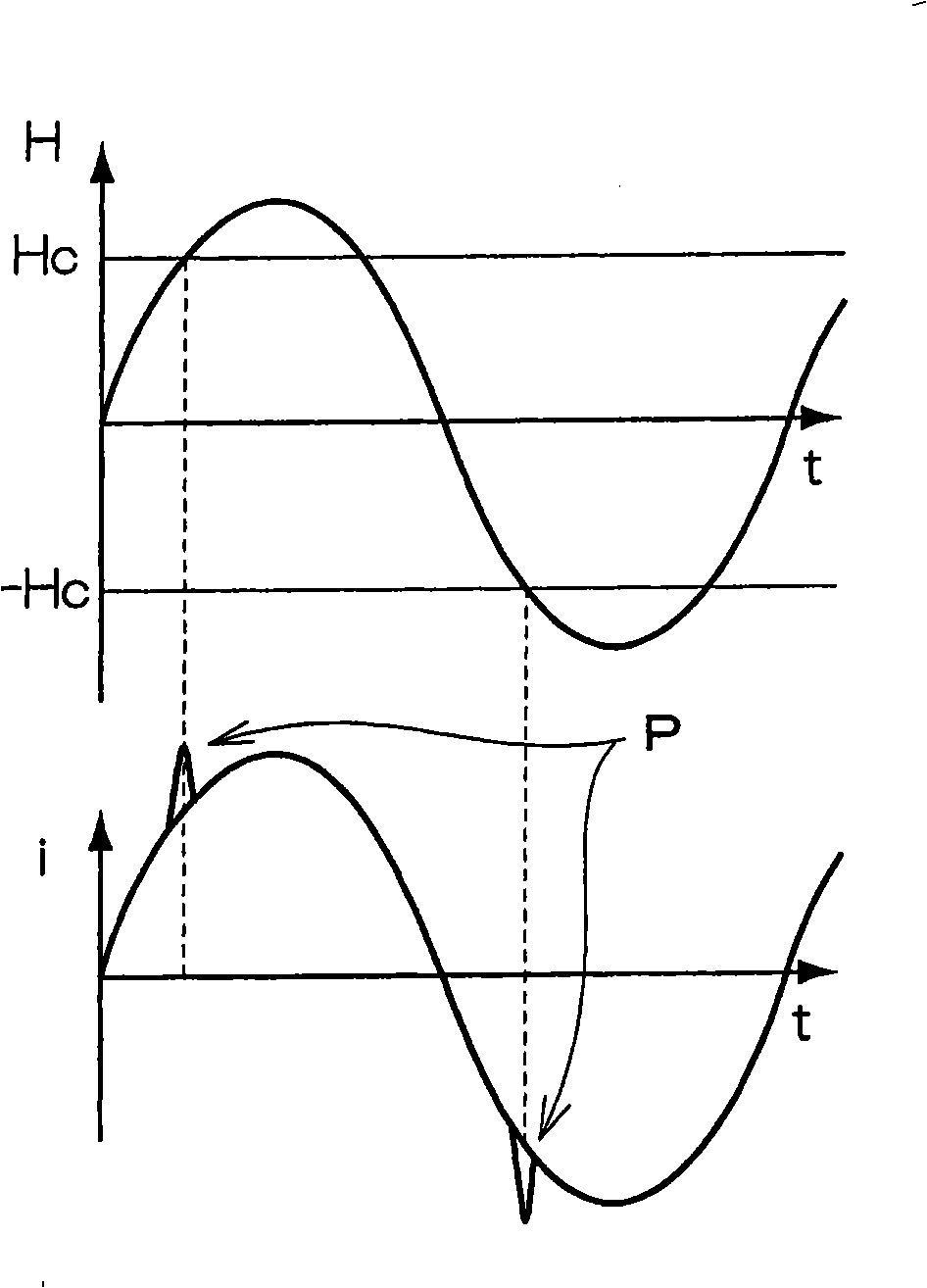

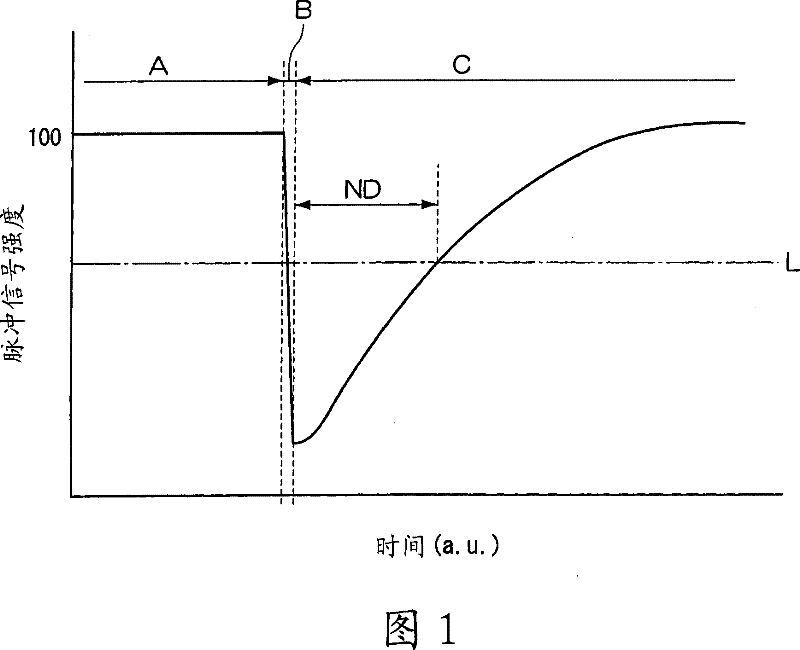

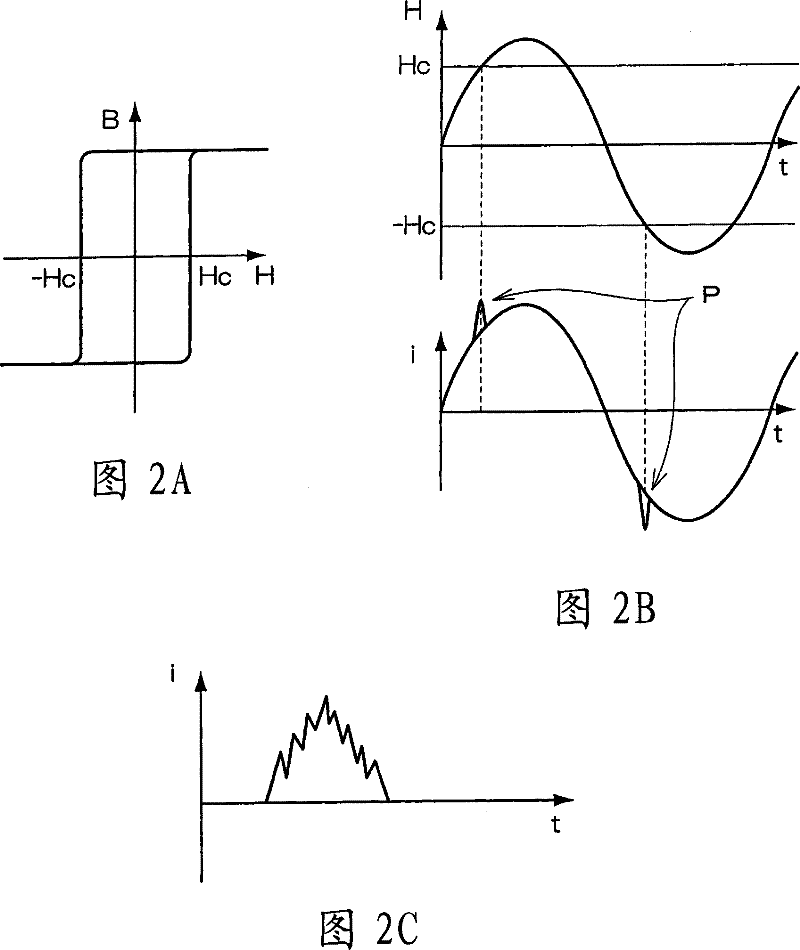

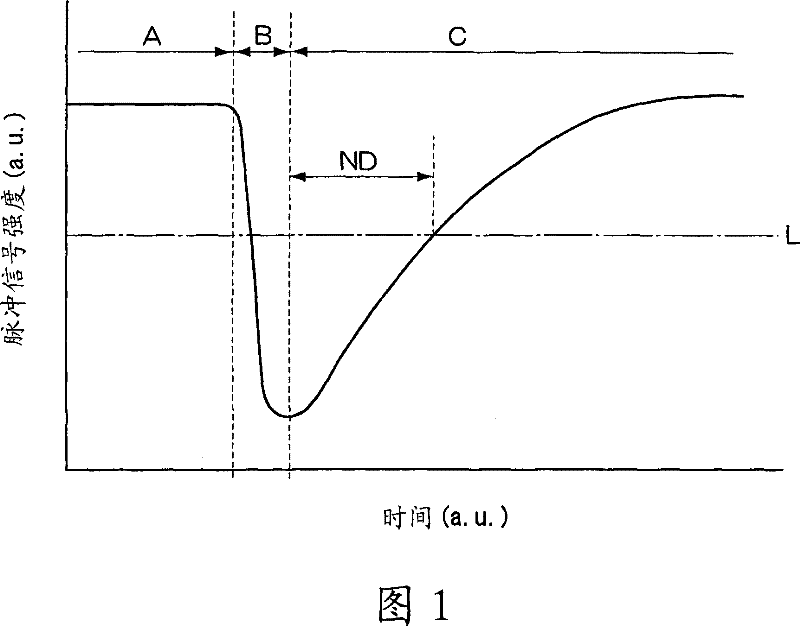

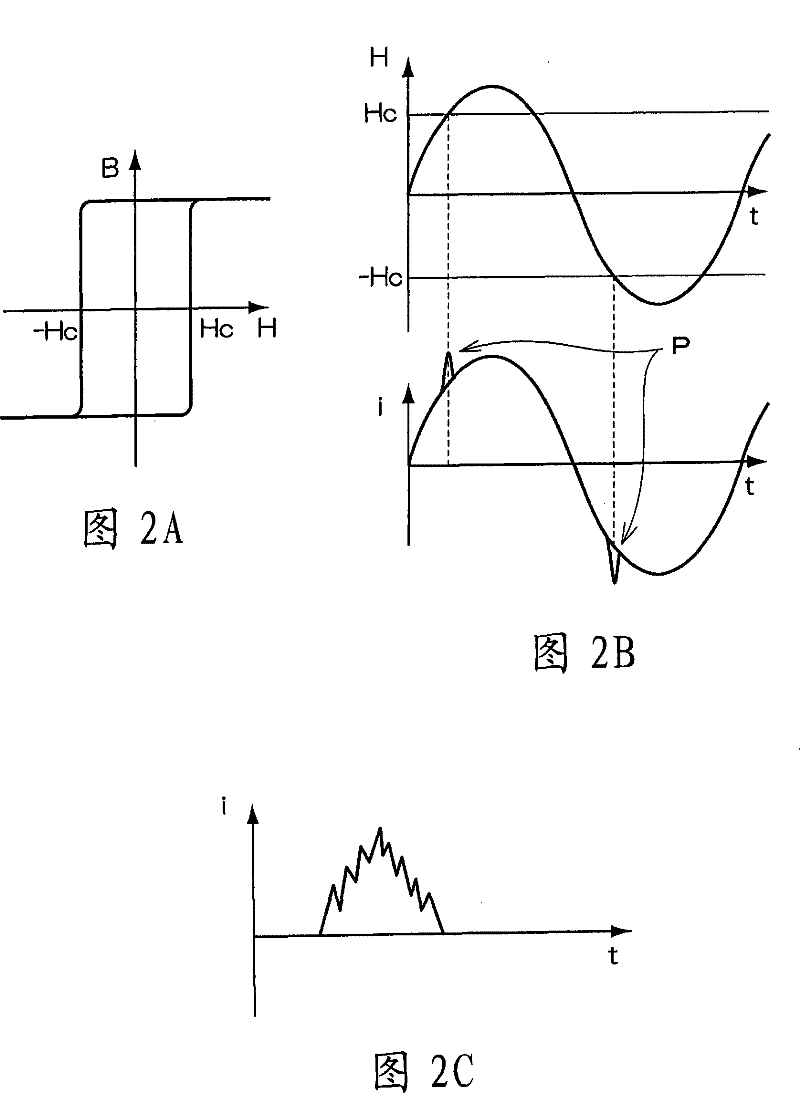

The present invention provides a defect and stress non-destructive testing system and non-destructive testing method based on pulsed eddy current and Barkhausen, and belongs to the field of non-destructive testing. According to the present invention, the system comprises an excitation signal generator, a digital-to-analog converter, a power amplifier, an excitation coil, a Hall sensor, a signal amplification circuit, a data acquisition card and a computer; on the basis of eddy current testing, based on the ferromagnetic material, the mixed wave of the rectangular wave and the triangular wave is adopted as the excitation signal, the rectangular wave band at the first half section in the mixed signal produces the pulsed eddy current phenomenon, the triangular wave band at the later half section in the mixed wave produces the barkhausen effect, the sectional treatment is performed on the signal by using a signal time domain average method to achieve the separation of the eddy current signal and the Barkhausen noise signal, and the signal is respectively subjected to feature extraction and data processing so as to concurrently achieve online detection of the surface defect, the stress and the microstructure state of the ferromagnetic material and achieve the discrimination of the ferromagnetic material recessive defect, the prediction of the defect being not yet formed, and the prediction of the service life; and the method has characteristics of long-term and reliable work, high sensitivity, simpleness, intuitive display, high efficiency, feasibility, and the like.

Owner:江苏高特高金属科技有限公司

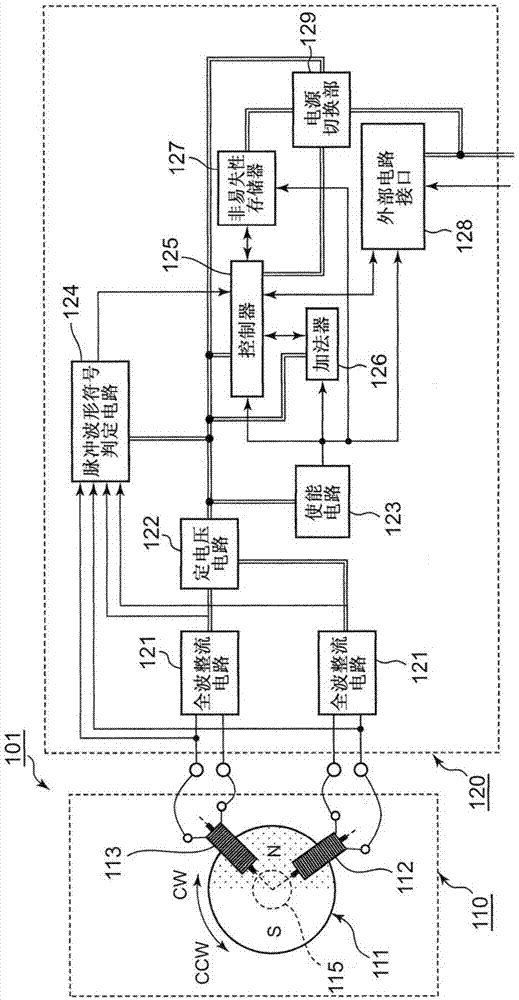

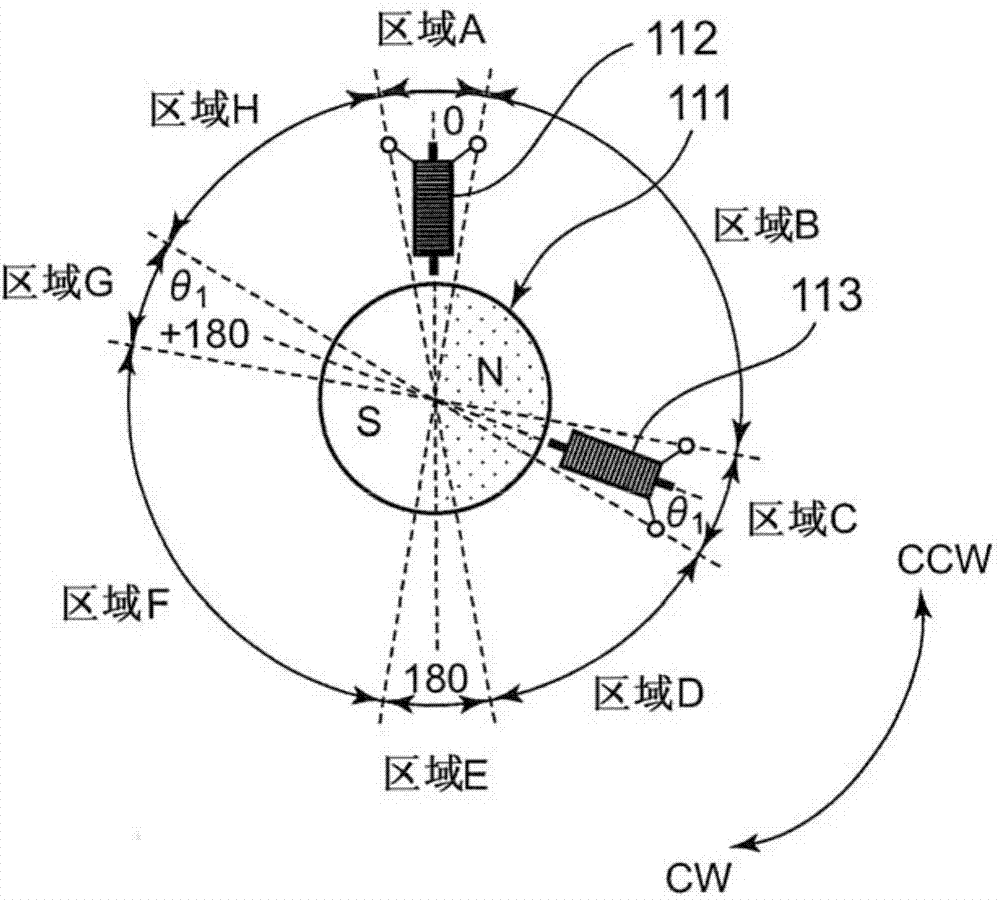

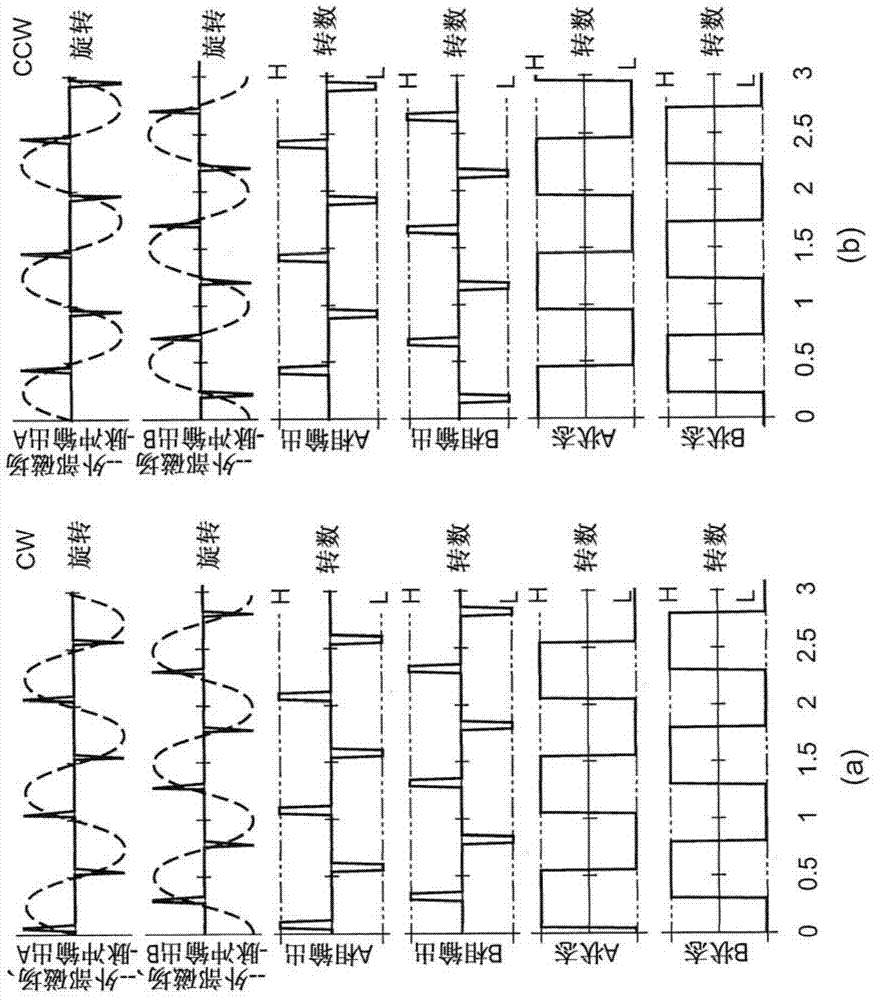

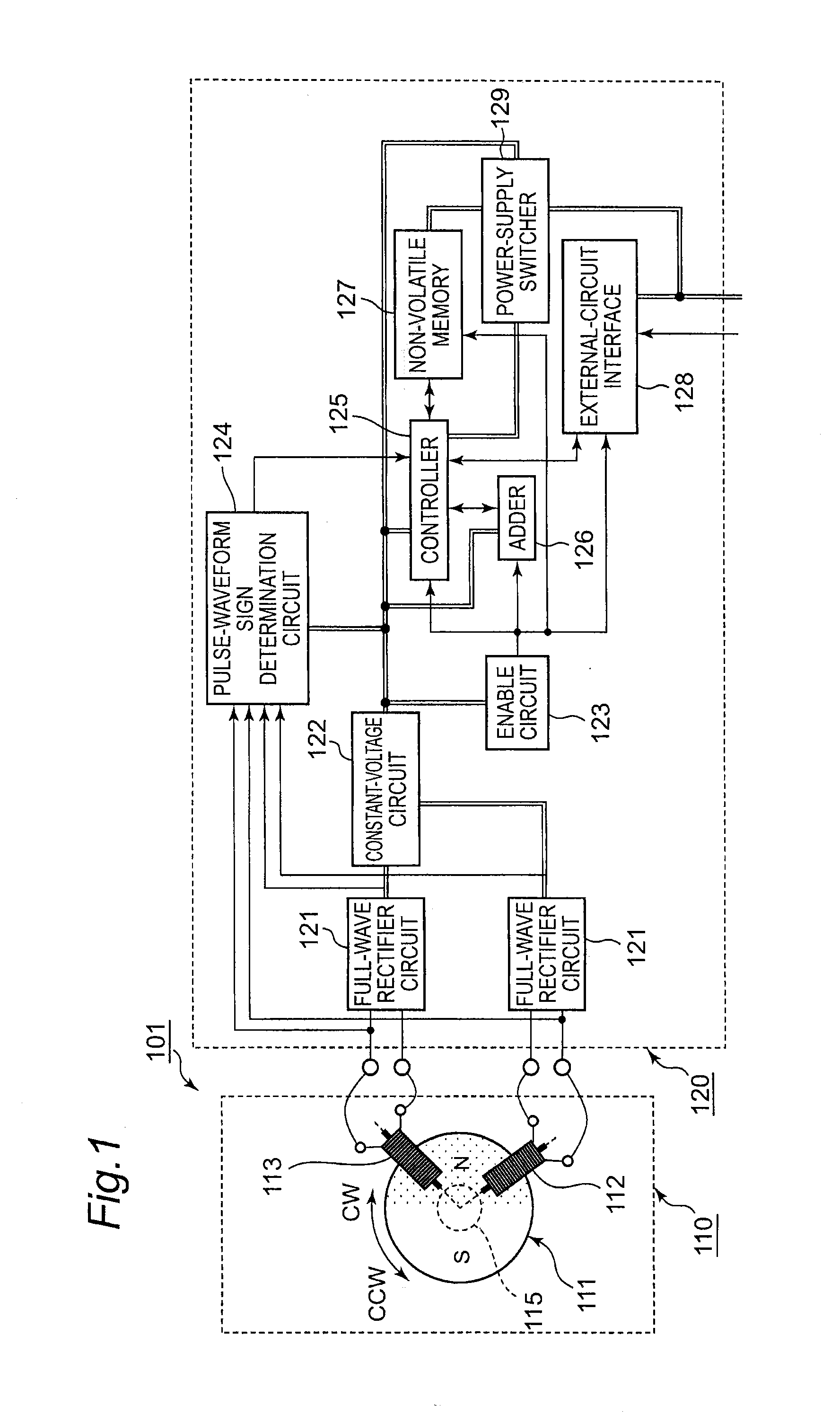

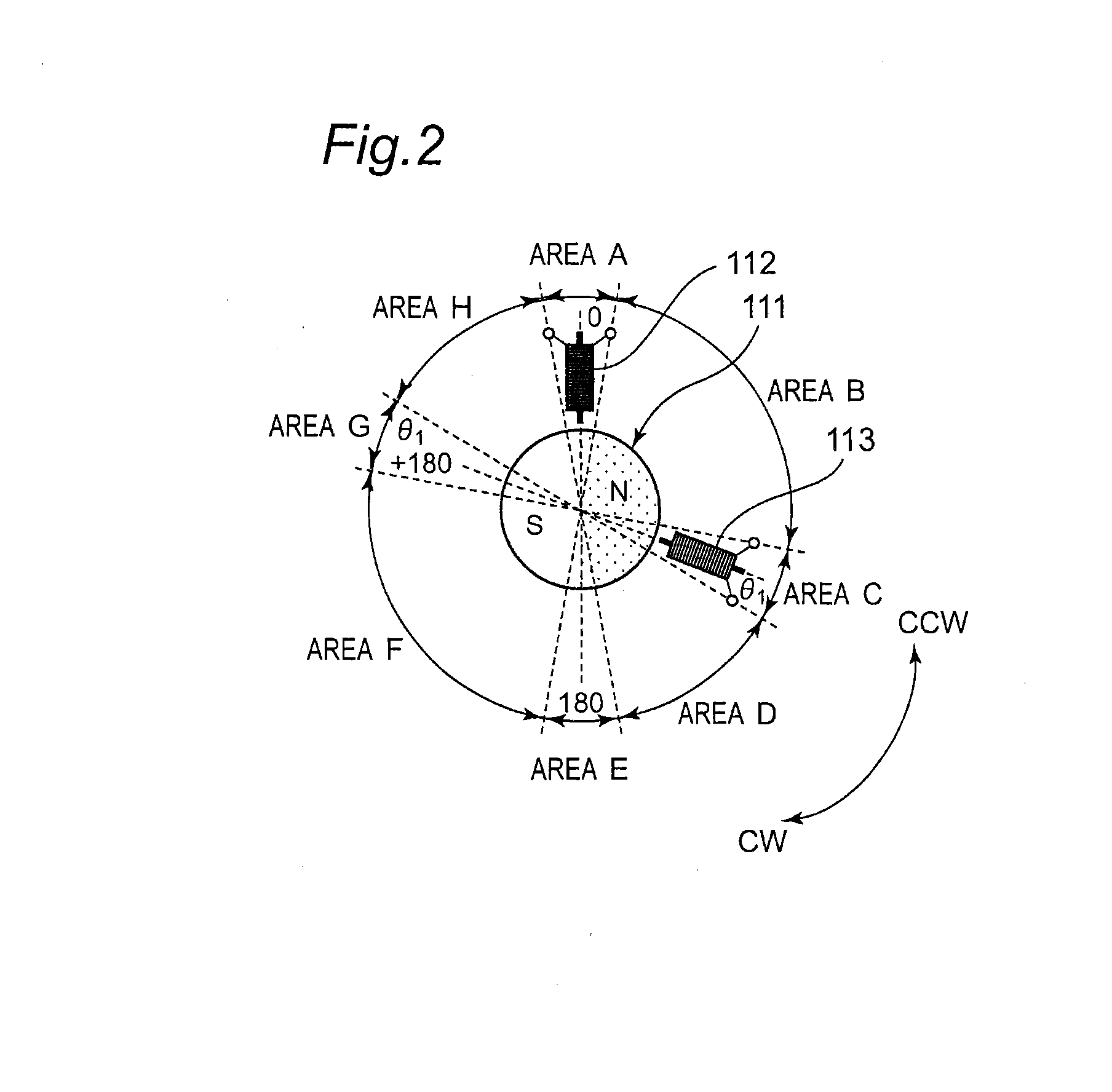

Multi-rotation encoder

InactiveCN104246444AAccurate detectionUsing electrical meansConverting sensor output electrically/magneticallyState variationVoltage pulse

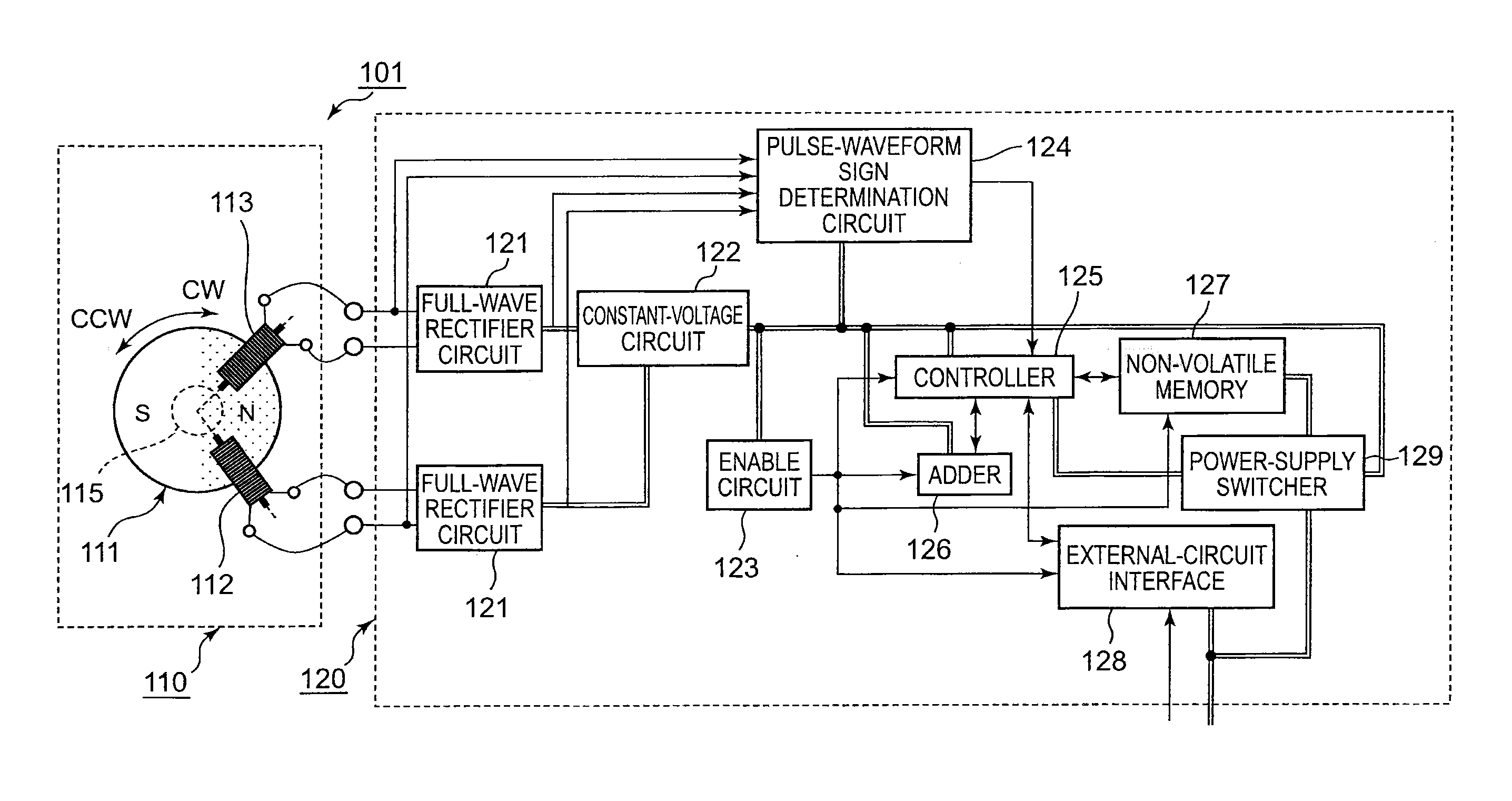

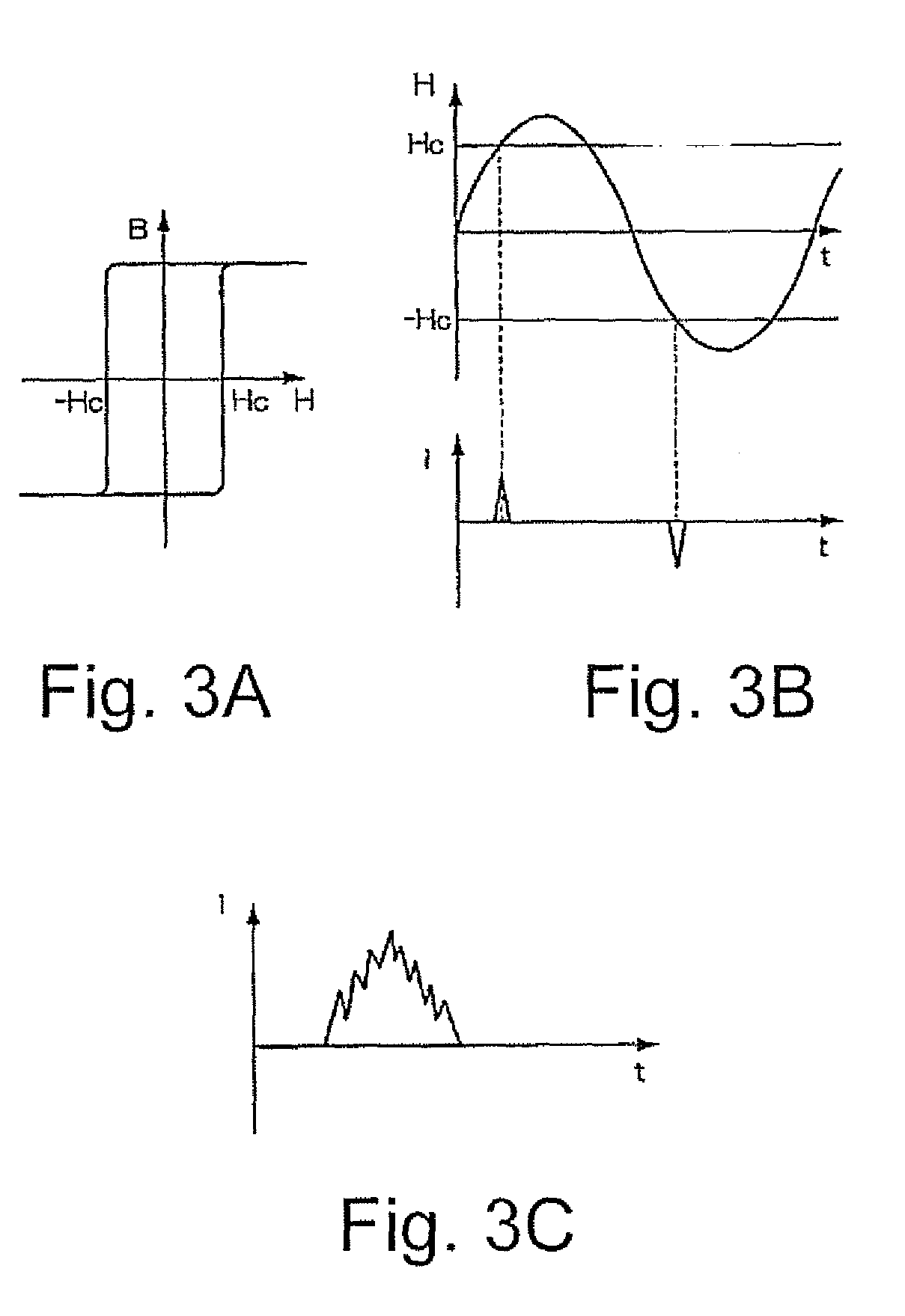

A multi-rotation encoder having detection coils (112, 113) having a Barkhausen effect, wherein a rotation detection mechanism (110) and a signal processing circuit (120) are provided, the detection coils generate positive / negative opposite-sign voltage pulses and transmit the voltage pulses to the signal processing circuit, the signal processing circuit has a controller (125) for storing the state of the detection coils as high or low in a memory (127) and maintaining the high or low state on the basis of the positive or negative sign of the voltage pulses and whether a voltage pulse is not being generated, and an adder (126) for updating a number of rotations in accordance with changes in the state of the detection coils, and the rotation angle of a rotary shaft is determined to within approximately 1 / 4 rotation units.

Owner:MITSUBISHI ELECTRIC CORP

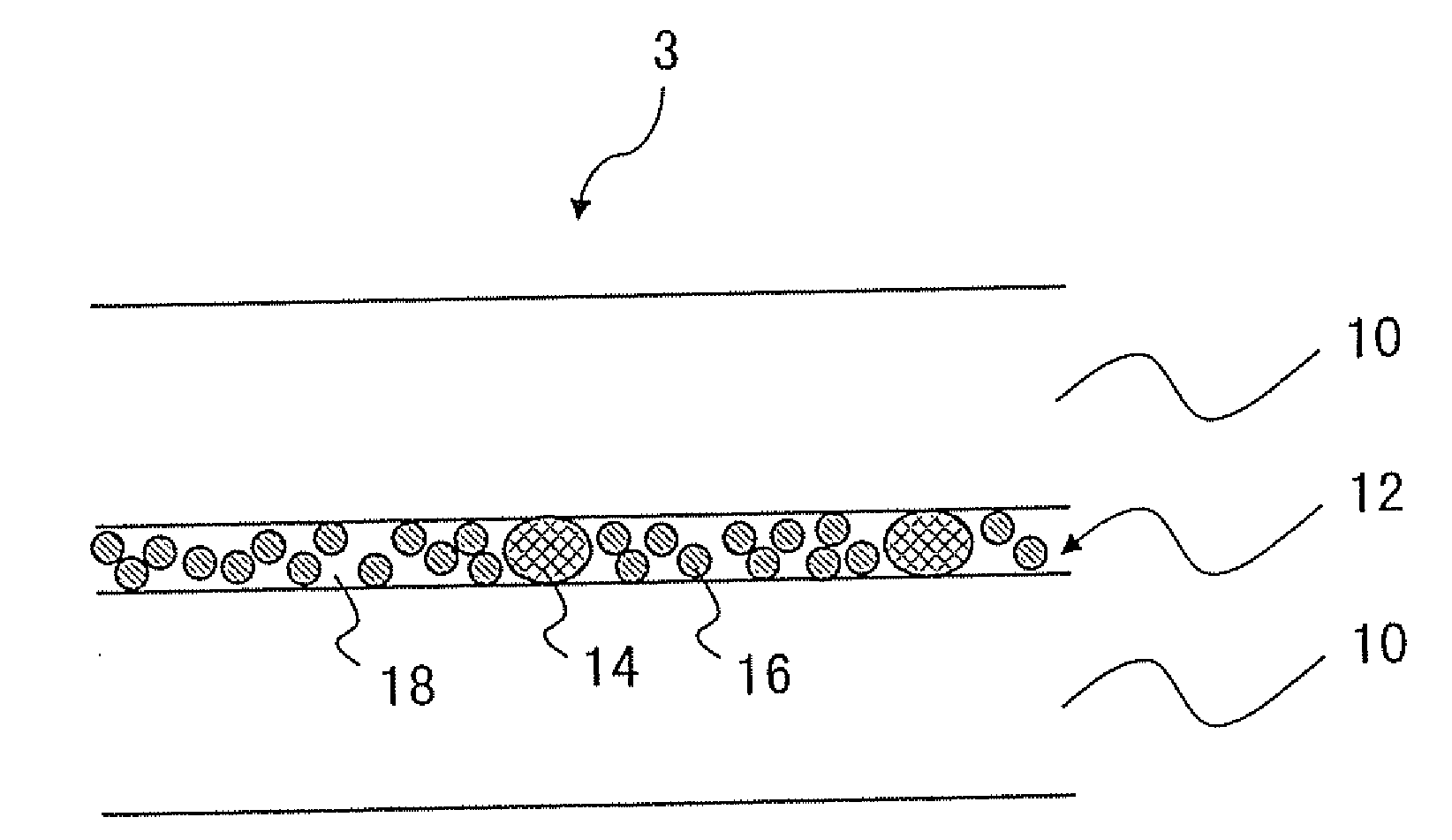

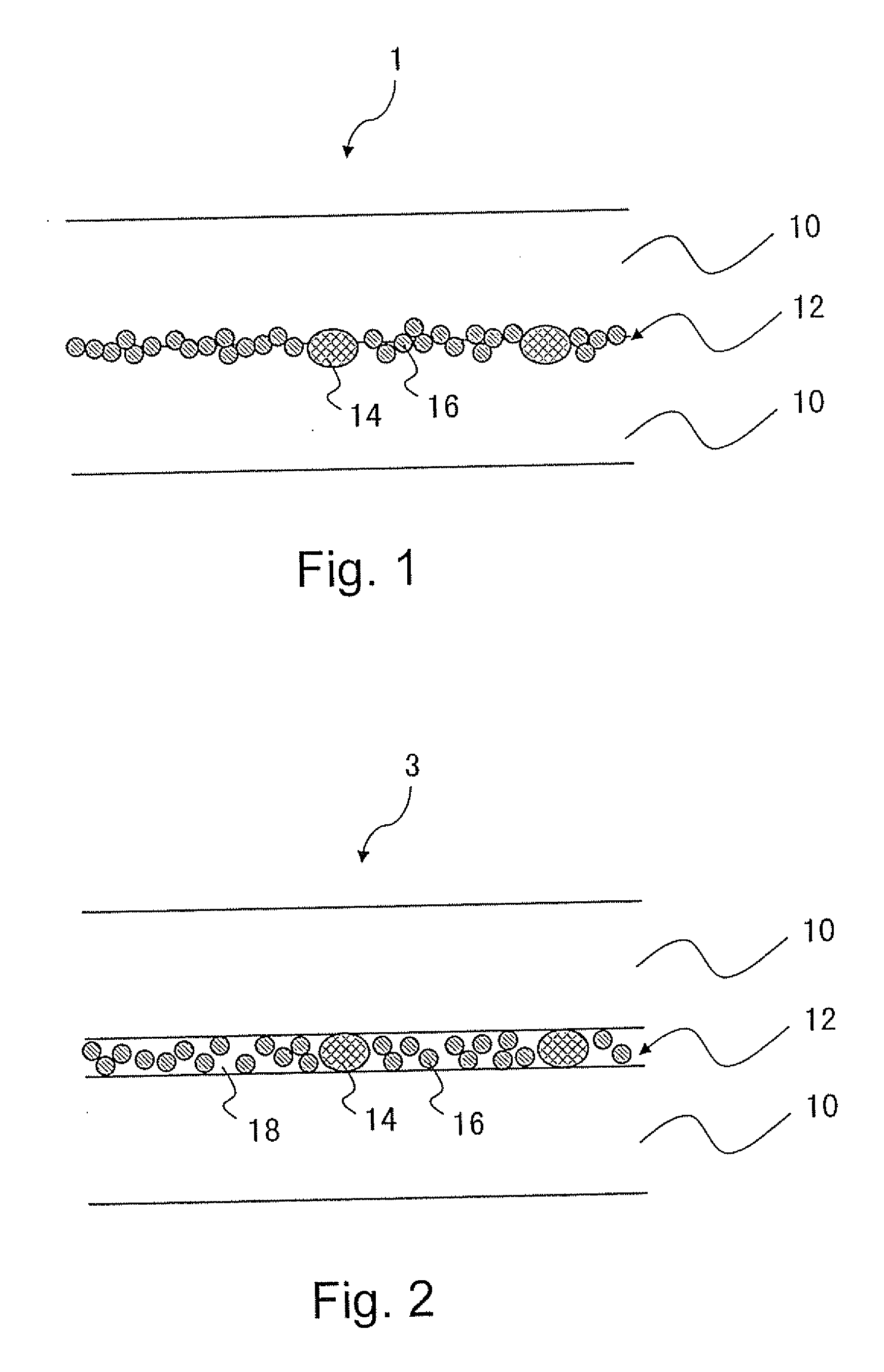

Recording paper

ActiveUS20090017334A1Non-fibrous pulp additionSpecial paperBarkhausen effectElectrical and Electronics engineering

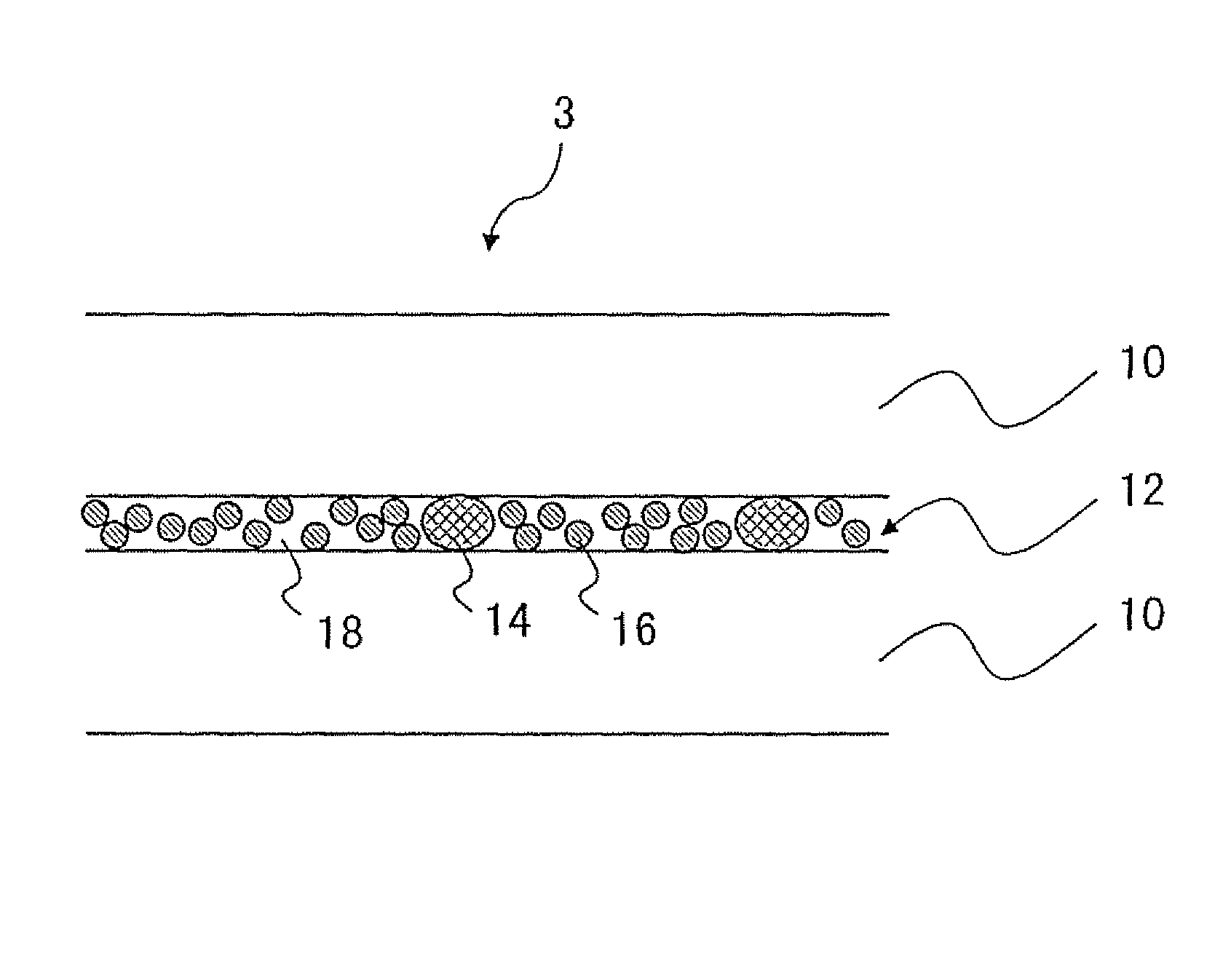

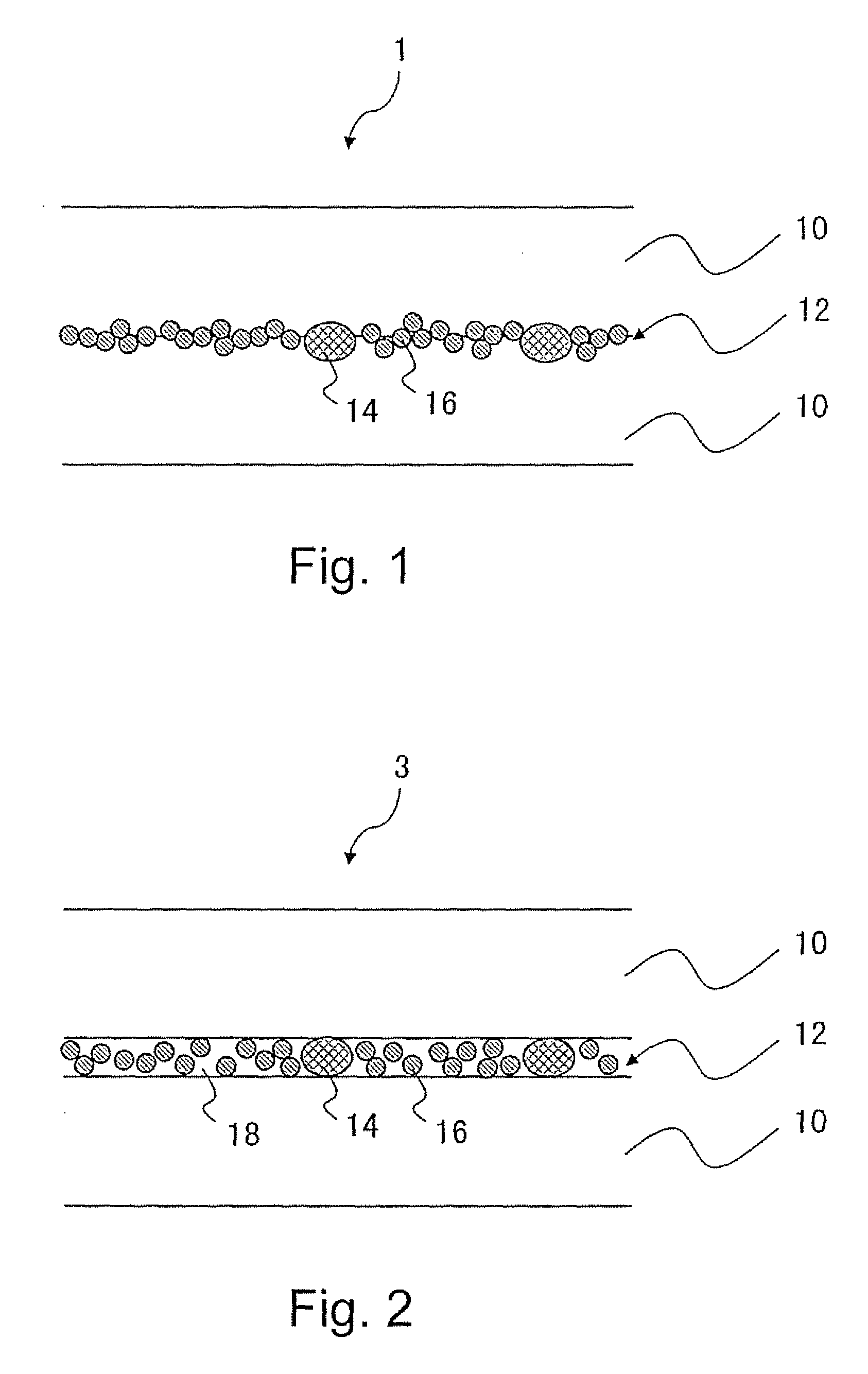

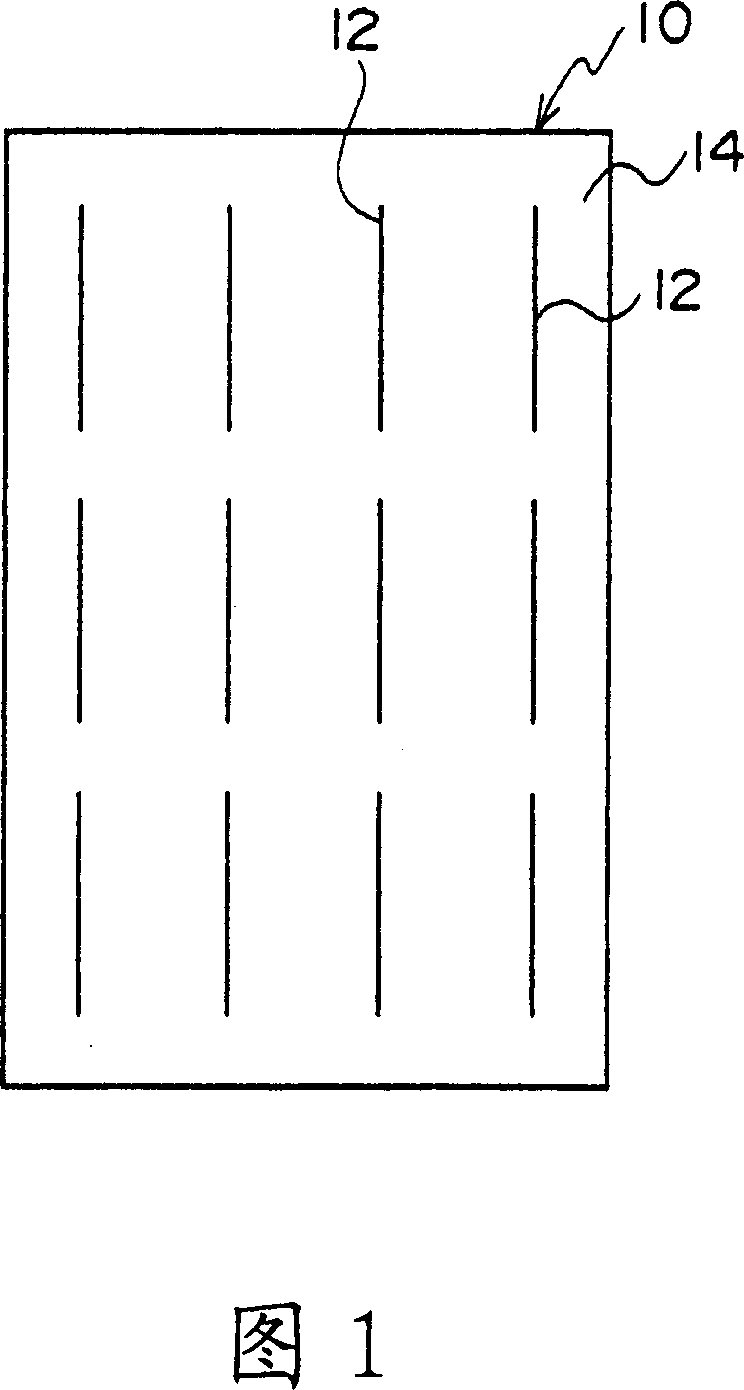

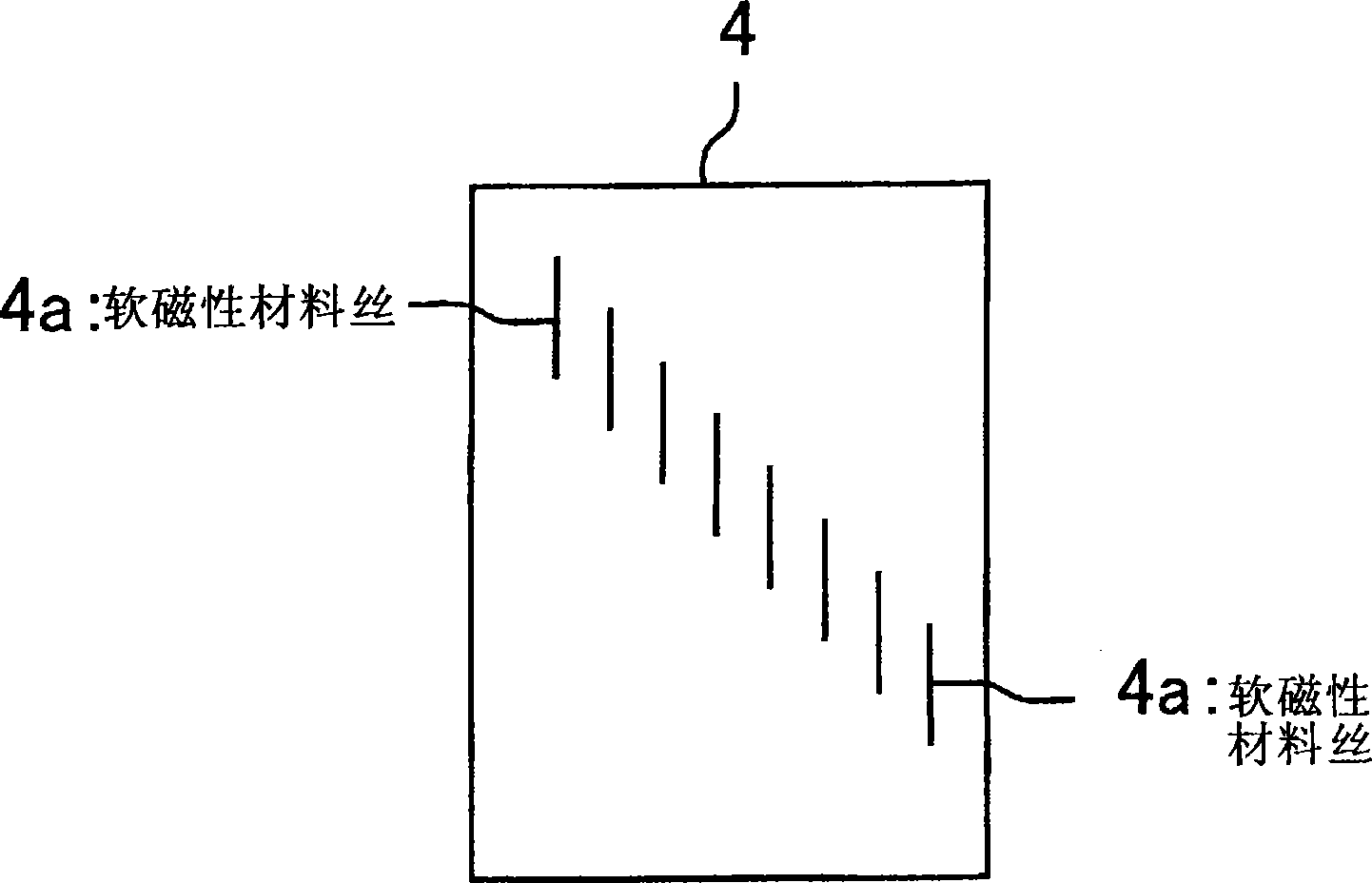

A recording paper having a magnetic material-containing layer, that includes a magnetic material that generates a large Barkhausen effect and a filler, and is disposed between pulp layers containing a pulp.

Owner:FUJIFILM BUSINESS INNOVATION CORP

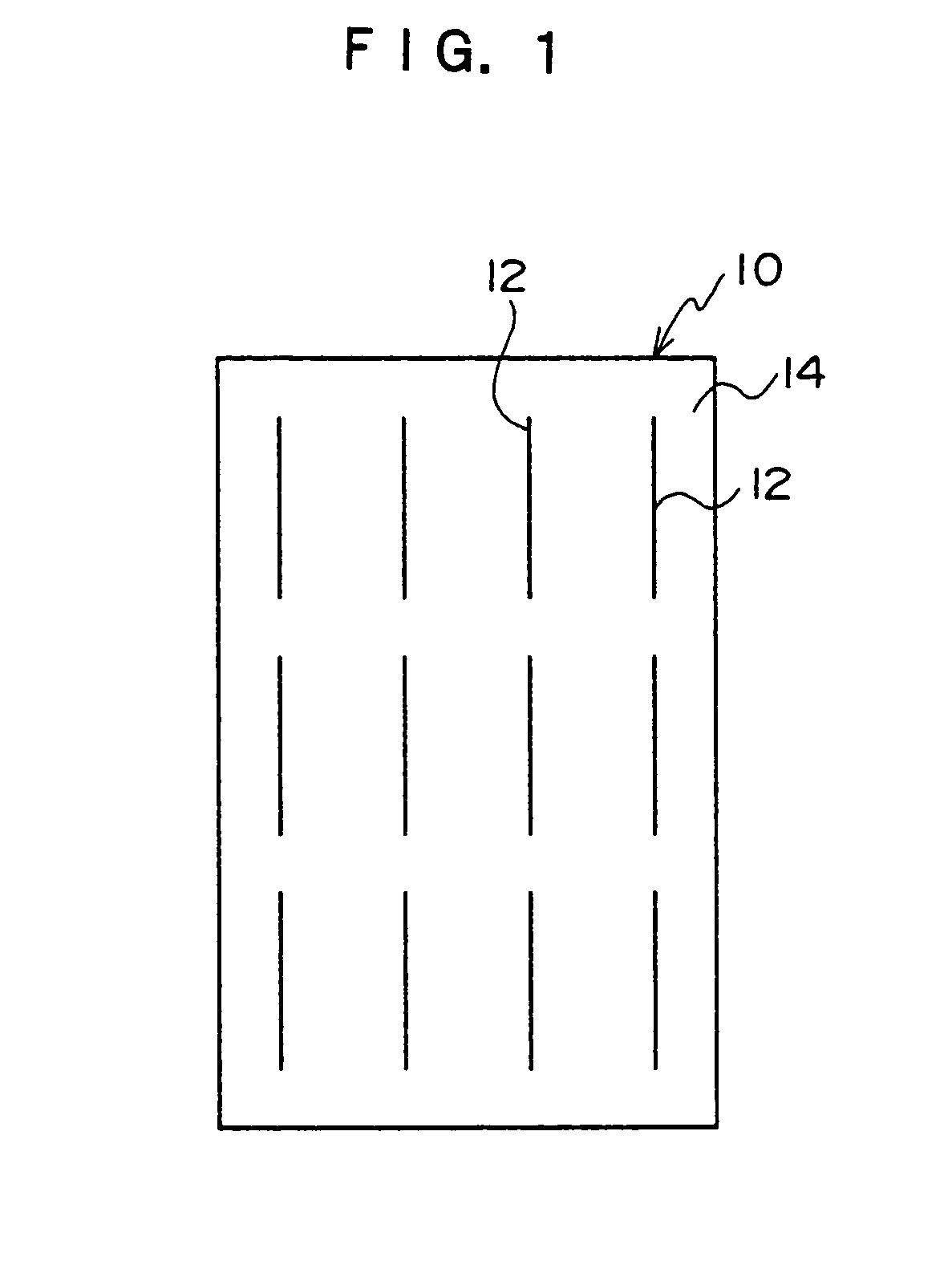

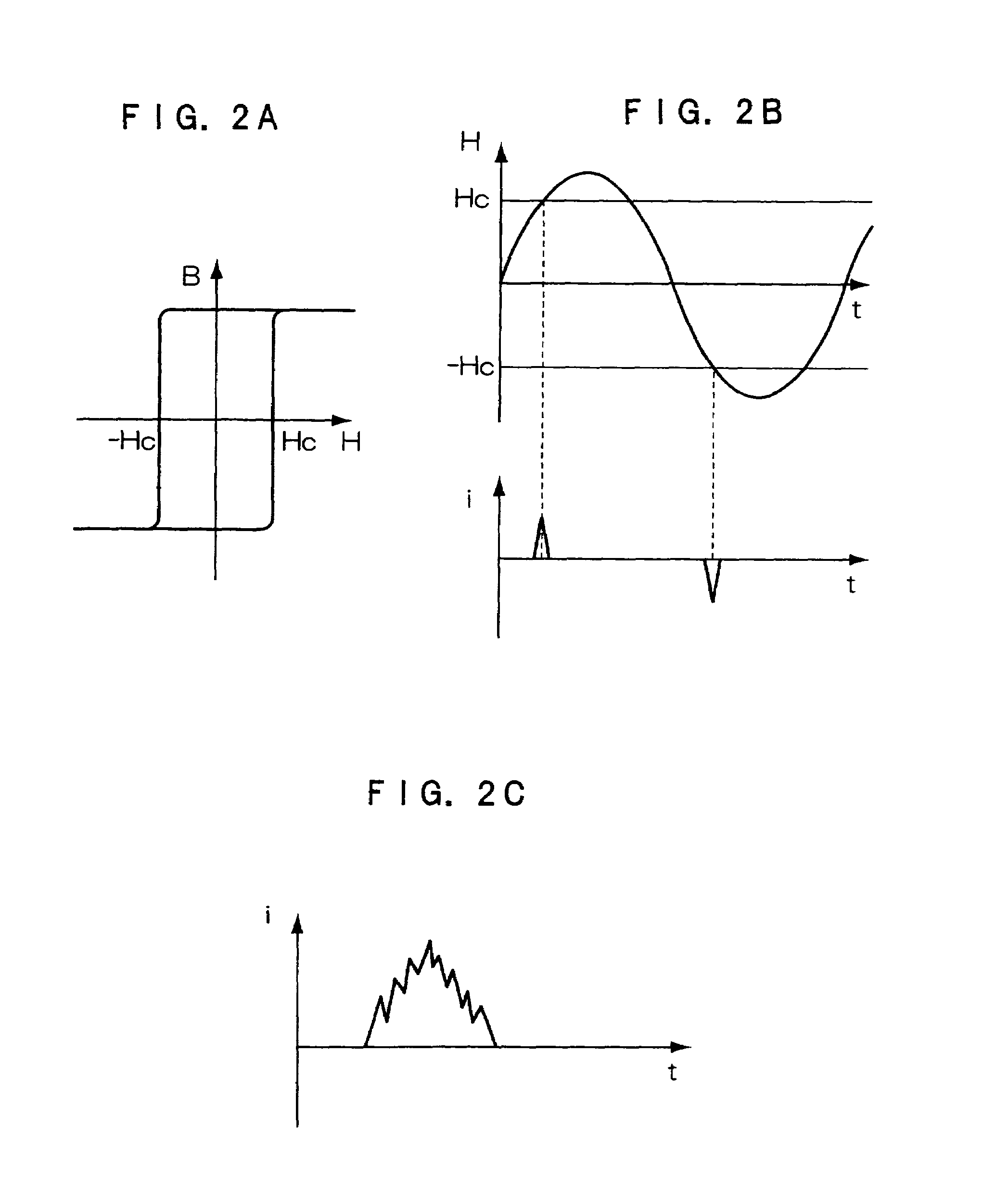

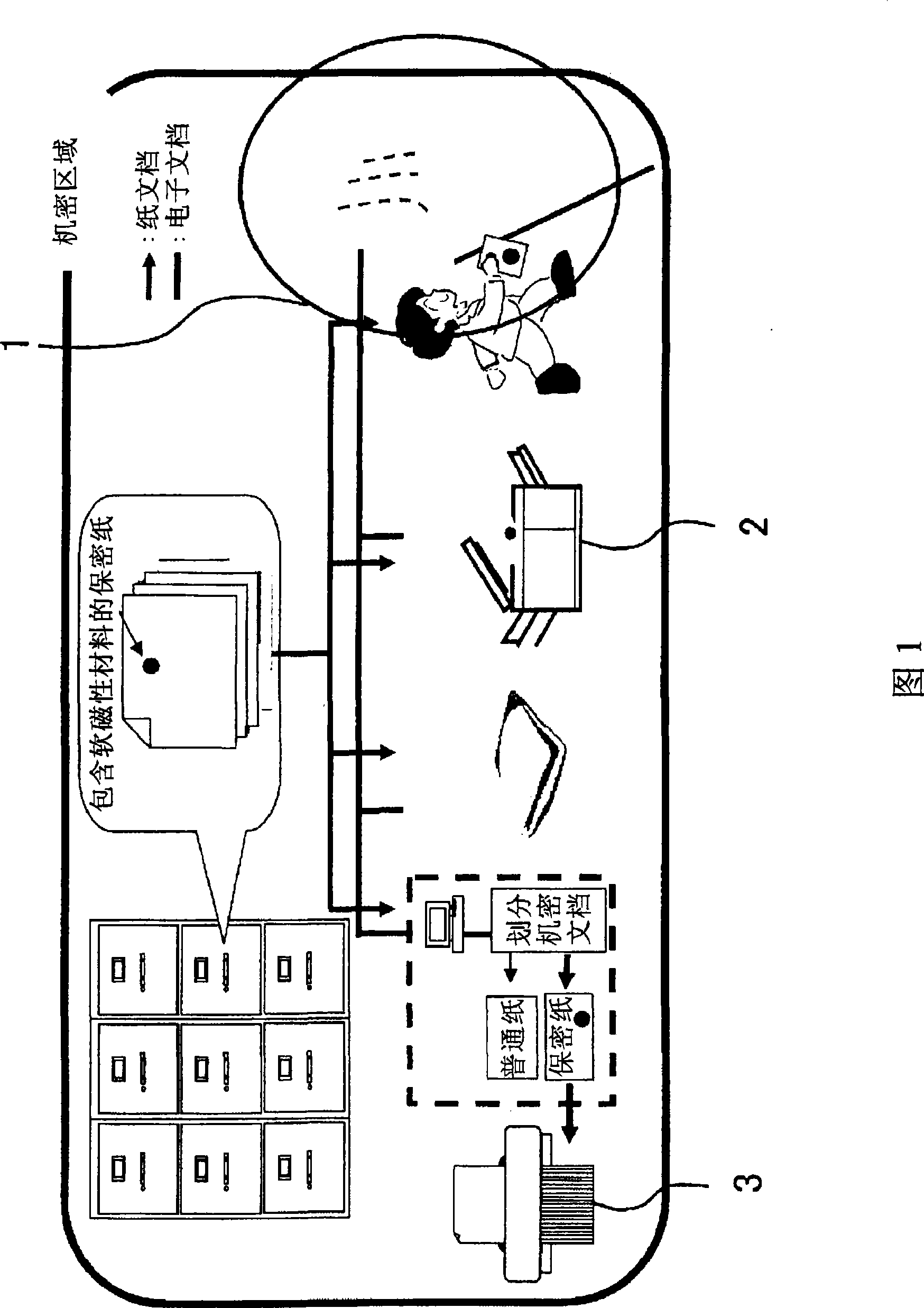

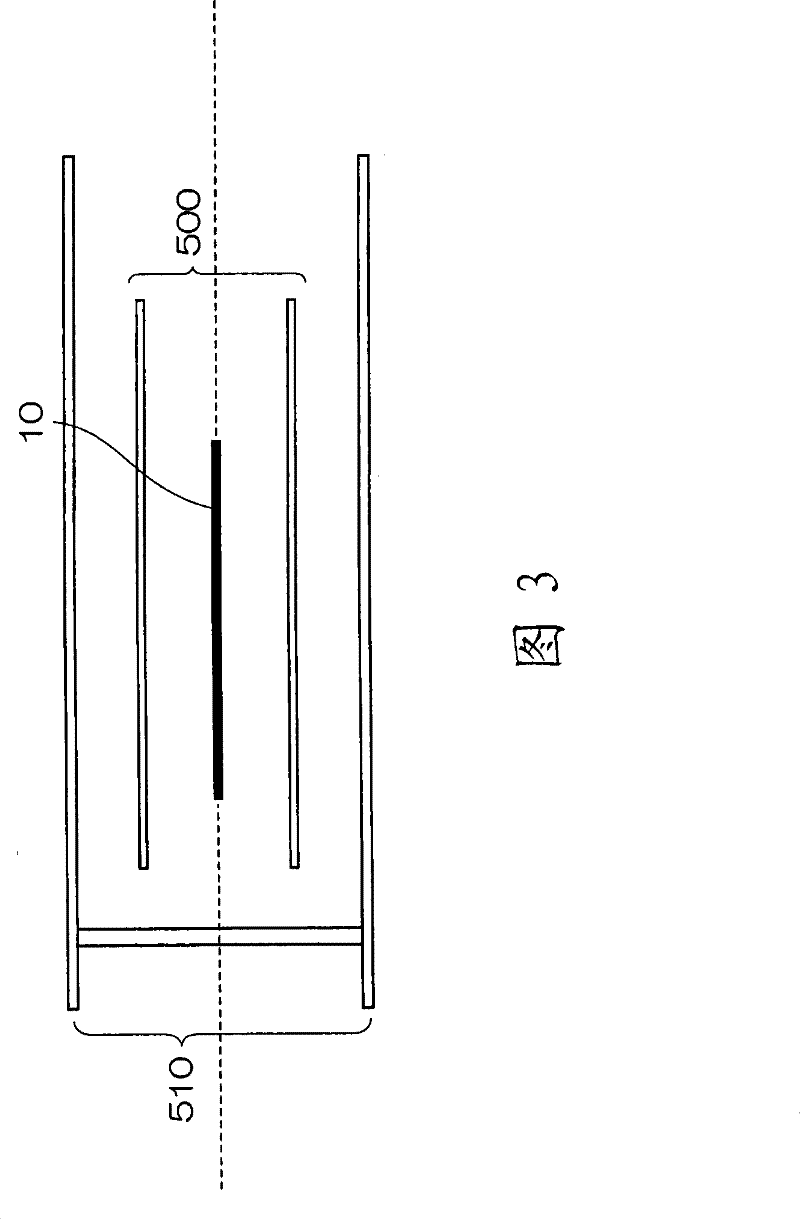

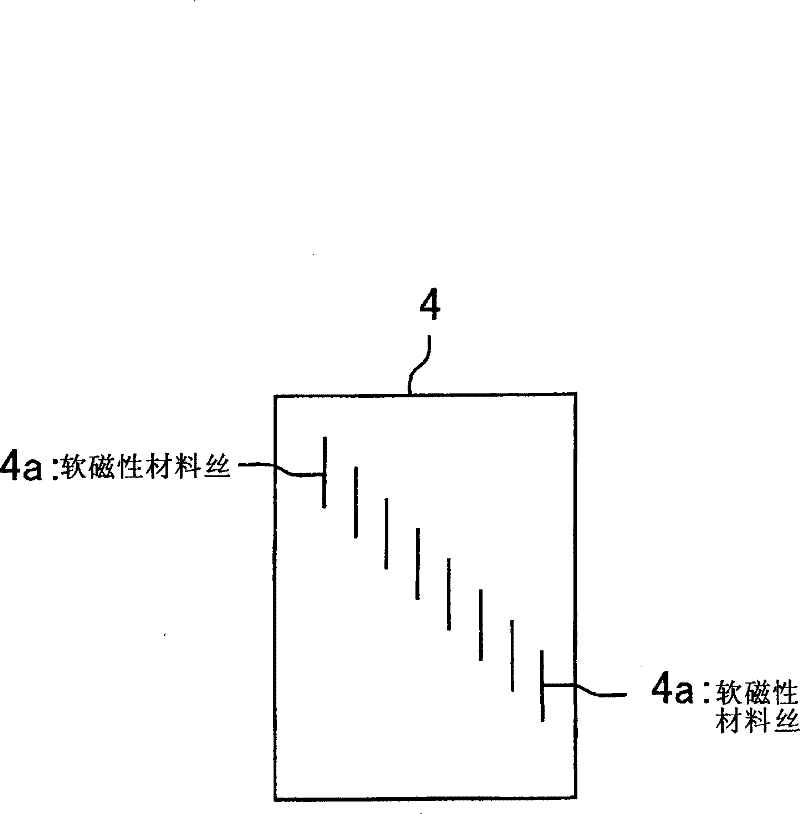

Recording medium detecting system

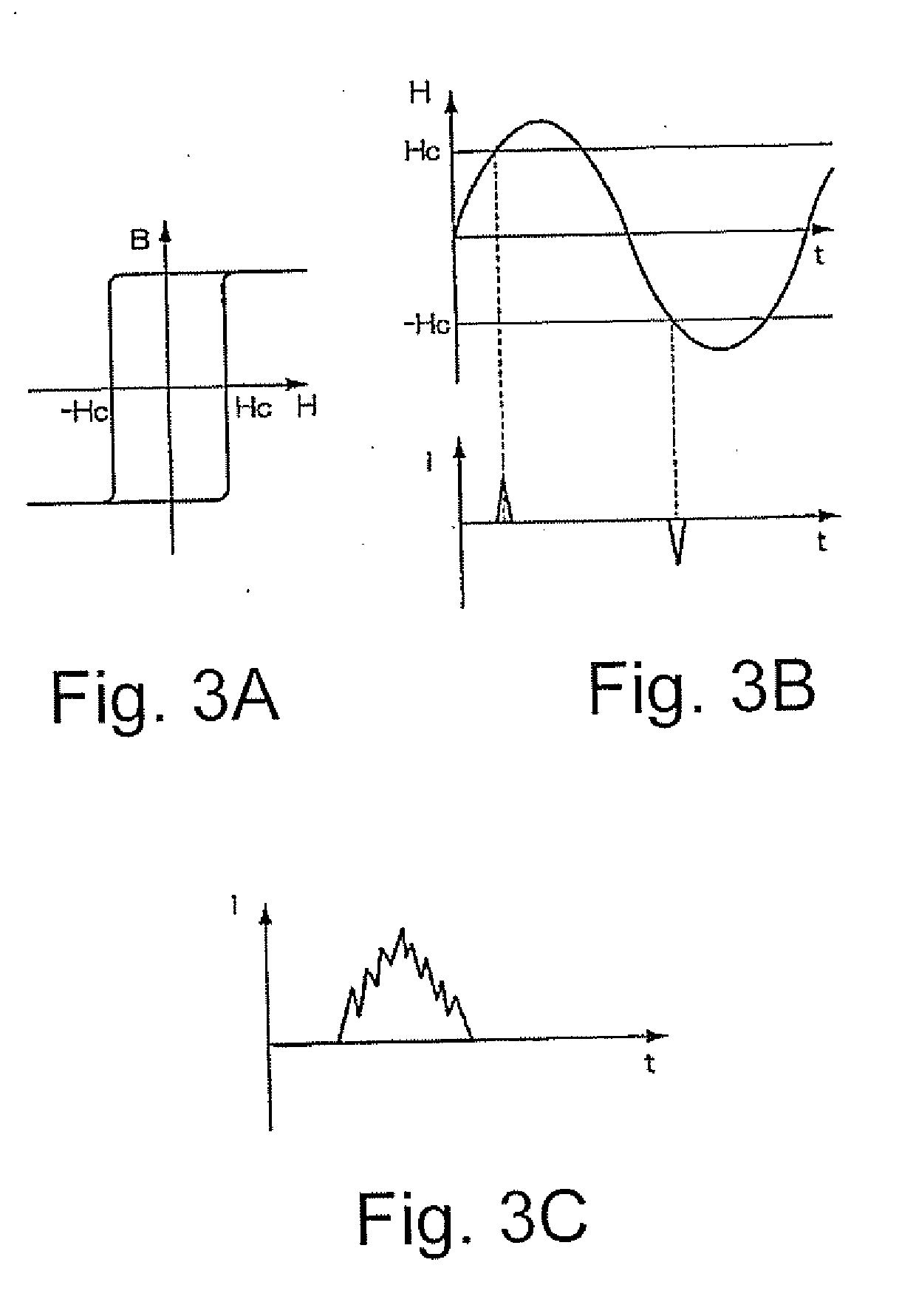

InactiveUS7301324B2Resistance/reactance/impedenceCurrent/voltage measurementEngineeringDensity difference

A recording medium detecting system includes a magnetic field-generating unit that generates an alternating magnetic field in a predetermined particular region, a detecting unit provided close to the particular region, that detects a change in magnetic flux density not smaller than a predetermined magnetic-flux-density difference B2, and a recording medium, containing multiple magnetic wires made of a magnetic material and formed in a wire shape having a predetermined length, that causes a large Barkhausen effect when the alternating magnetic field is applied. A magnetic-flux-density difference B1 detected by the detecting unit at an installation position thereof when the recording medium is placed in the particular region is not smaller than the magnetic-flux-density difference B2.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Recording paper

ActiveCN101265680ASuppresses temporary degradation of signal strengthShrinkage adjustmentNon-fibrous pulp additionSpecial paperEngineeringFiber orientation

A recording paper contains a pulp fiber and a magnetic fiber having a large Barkhausen effect. The fiber orientation ratio of this recording paper by an ultrasonic propagation velocity method is in a range of more than 1.3 to less than 1.8, and the degree of shrinkage in an MD thereof is 0.25% or less.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Multi-rotation encoder

InactiveUS20150015245A1Improve accuracyUsing electrical meansConverting sensor output electrically/magneticallyVoltage pulseSignal processing circuits

A battery-less multi-rotation encoder including detection coils with the Barkhausen effect includes a rotation detection mechanism and a signal processing circuit. The detection coils generate voltage pulses with different positive and negative signs, and transmit them to the signal processing circuit, and the signal processing circuit includes a controller and an adder. The controller can set states of the detection coils to be High or Low and to maintain them at High or Low, based on the positive and negative signs of the respective voltage pulses and no voltage pulse being generated therefrom. The controller is configured to store the states of the respective detection coils in a memory. The adder can update a number of rotations according to the changes in the states of the respective detection coils. The signal processing circuit can determine the rotational angle of a rotational shaft within about 1 / 4 rotation unit.

Owner:MITSUBISHI ELECTRIC CORP

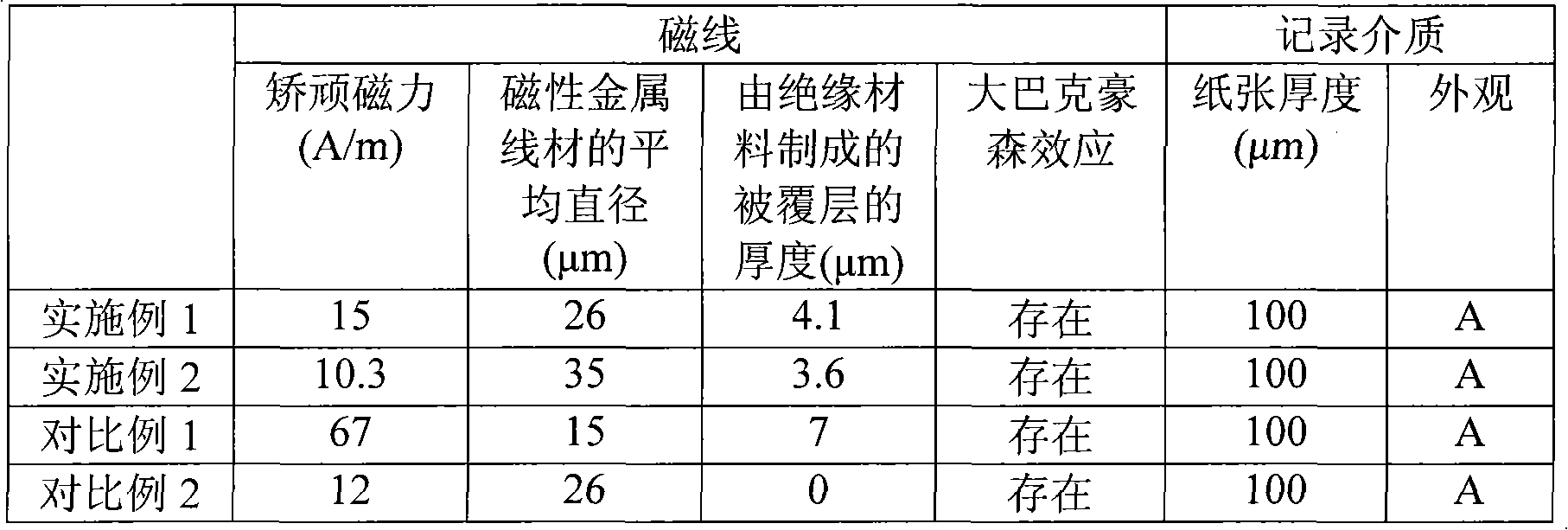

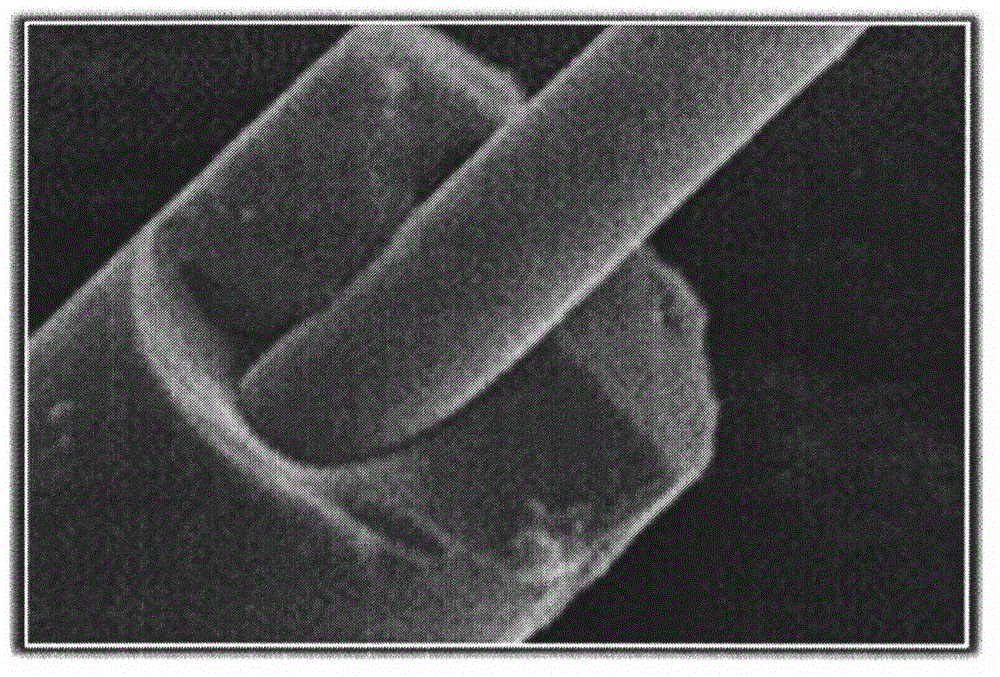

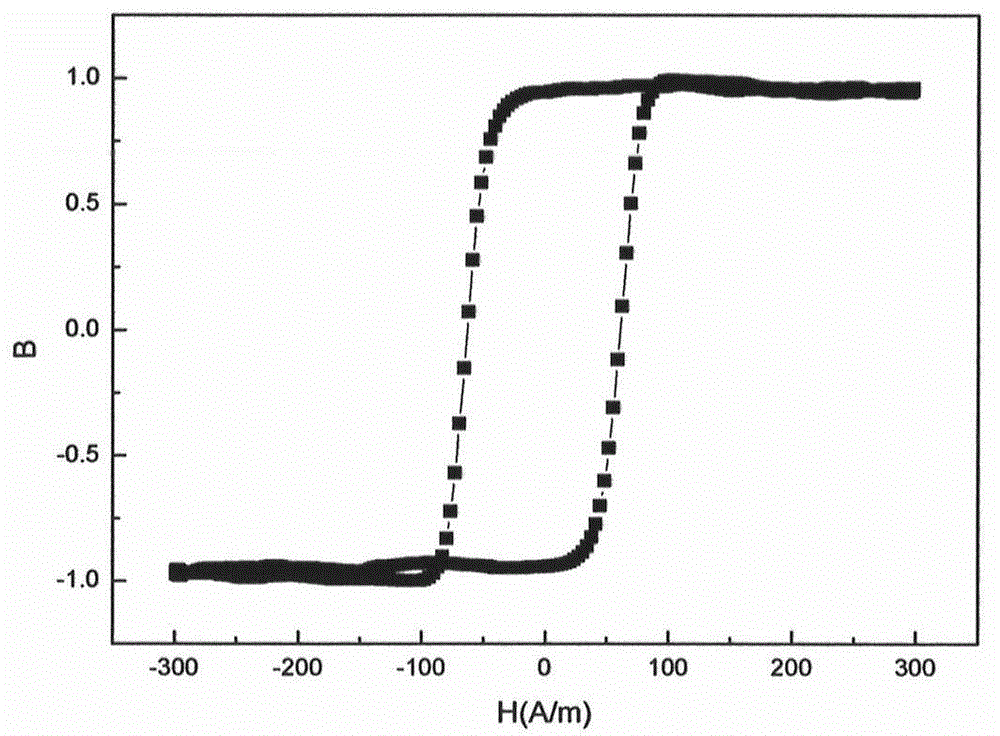

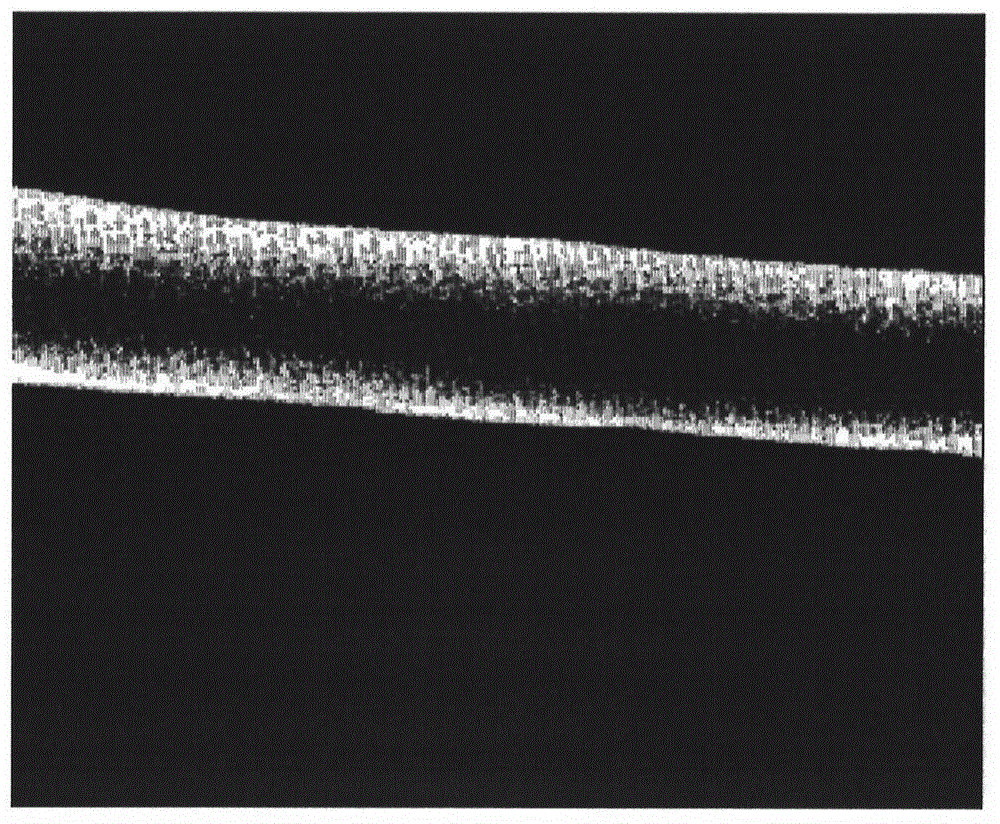

Magnetic wire and recording medium

The invention provides a magnetic wire and a recording medium. The magnetic wire includes a magnetic metal wire material having a surface coated with a layer of an insulating material. The magnetic wire has a magnetic coercive force of 30 A / m or less and has a Barkhausen effect.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Pulse signal generator

Owner:HIROSE ELECTRIC GROUP +1

Transfer paper for electrophotography

ActiveCN101265679ADetection accuracy dropsInhibition of prominenceSpecial paperDryer sectionFiberPulp and paper industry

A transfer paper for electrophotography contains a pulp fiber and a magnetic material for generating a large Barkhausen effect. An average dehydration speed S 1 a (an average value (% by mass / second) of dehydration speeds S 1 of 5 sheets of paper) is 0.15 or less. The dehydration speed S 1 is represented by (W 1 a-W 1 b) / 30. Here, W 1 a represents a moisture content ratio (% by mass) of the paper after moisture conditioning, and W 1 b represents a moisture content ratio (% by mass) of the paper after a dehydration process including leaving the paper in a 80 DEG C. environment for 30 seconds after moisture conditioning.

Owner:FUJIFILM BUSINESS INNOVATION CORP

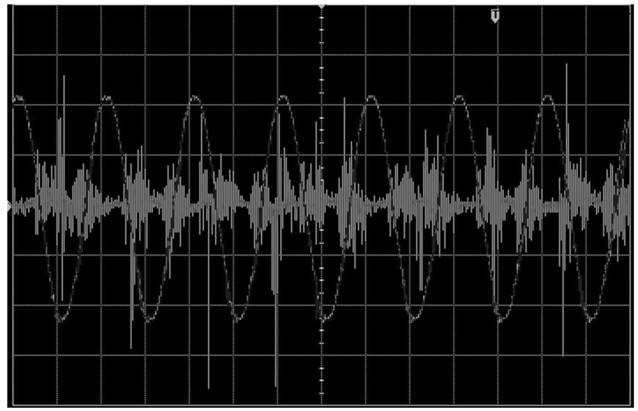

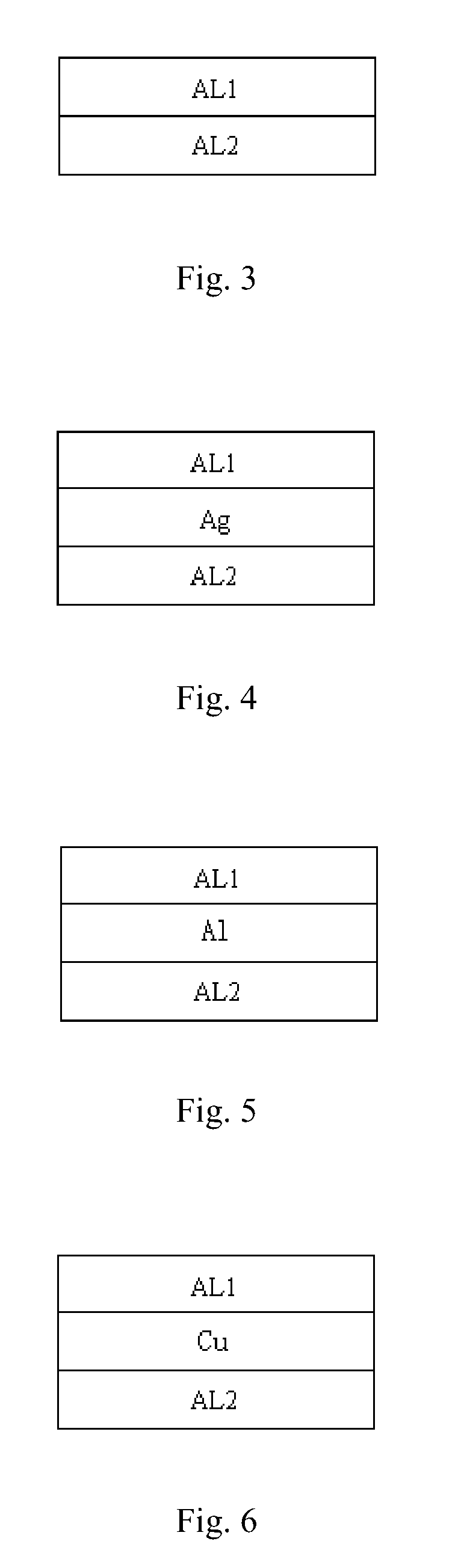

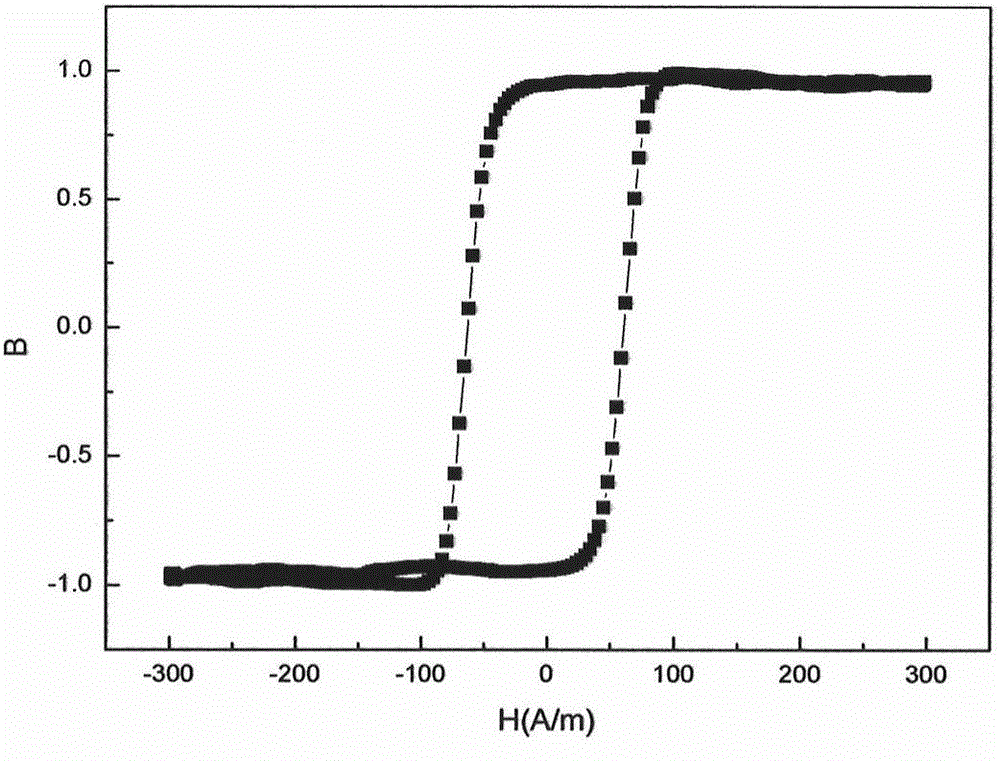

Security Functional Thin Film and Security Product Containing the Functional Thin Film

ActiveUS20100220371A1Improve security featuresNon-fibrous pulp additionNatural cellulose pulp/paperIn planeOptoelectronics

The present invention provides a security functional thin film and a security product containing such a thin film. The security functional thin film is of an amorphous structure, and possesses soft magnetic characteristics. Large Barkhausen effect can be detected along the in-plane preferred direction of magnetization; and the Large Barkhausen effect significantly attenuates, or no such signal can be detected, in a direction perpendicular to the in-plane preferred direction of magnetization. The thin film has a thickness of 20-300 nm, and the thin film also possesses element encoding characteristics that can be authenticated by experts. The security functional thin film of the present invention can be fabricated by magnetron sputtering web coating process. The security product provided by the present invention has a security information layer formed of the security functional thin film, and can be combined with other security characteristics for use in fabricating security materials such as security threads, security tapes, paper security strip-like inserts, or security labels, and others. Compared with conventional anti-counterfeiting technologies, the instant security functional thin film has more hidden security information, and facilitates enhancement of safety performance of security products.

Owner:CHINA BANKNOTE PRINTING & MINTING

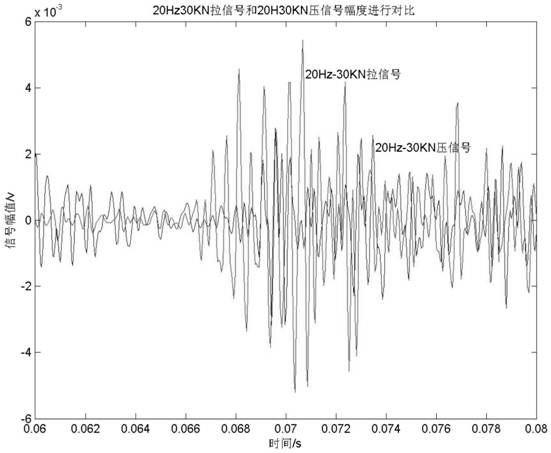

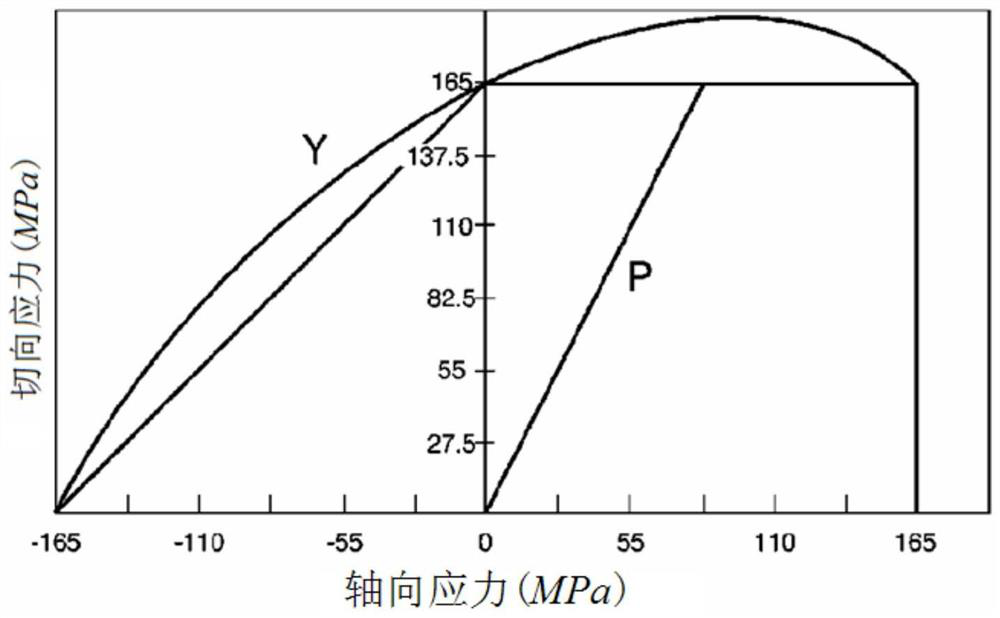

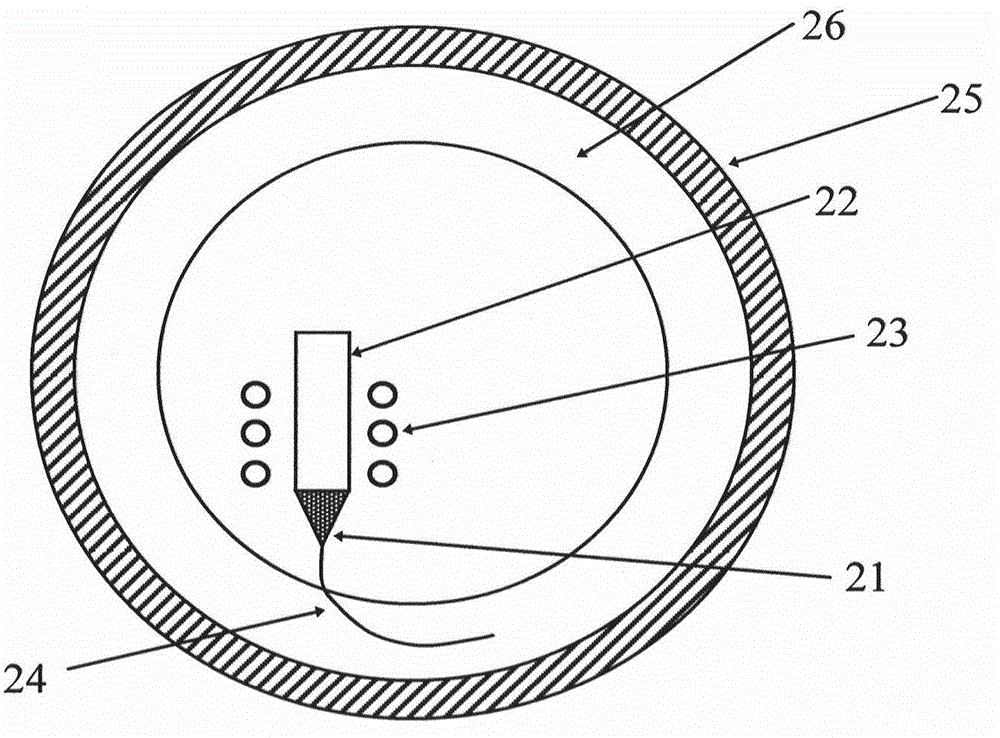

Method for measuring two-dimensional stress at weld joint by using Barkhausen effect and detection instrument

InactiveCN112945427AAchieve bi-directional stress detectionForce measurement by measuring magnetic property varationApparatus for force/torque/work measurementTangential stressNoise

The invention discloses a method for measuring two-dimensional stress at a weld joint by using a Barkhausen effect and a detection instrument. A ferrite magnetic core and a magnetic core of a Barkhausen measuring probe are directly contacted with the surface of the weld joint of the test piece, so that the X-direction tangential stress and the Y-direction axial stress of the weld joint of the test piece are calibrated; the Barkhausen measuring probe is used for collecting excitation signals and detecting Barkhausen signals, stress signal amplitude waveforms are obtained, and signal amplitude noise is obtained according to the waveforms; a Barkhausen noise signal amplitude is extracted from a signal detected by the Barkhausen measuring probe, the Barkhausen noise signal amplitude continuously changes along with the tension and pressure stress values to form a tension and pressure fitting curve, and the tension and pressure fitting curve serves as a calibration result of the relation between the Barkhausen noise signal amplitude and the continuous tension and pressure stress; and finally, a Barkhausen noise signal, the residual stress sigma1 in the vertical direction, the residual stress sigma2 in the parallel direction and the quantitative relation of the included angle theta between the main stress direction and the magnetic field direction are obtained, and the two-dimensional residual stress of the welding area is directly detected.

Owner:思特尔智能检测系统(苏州)有限公司

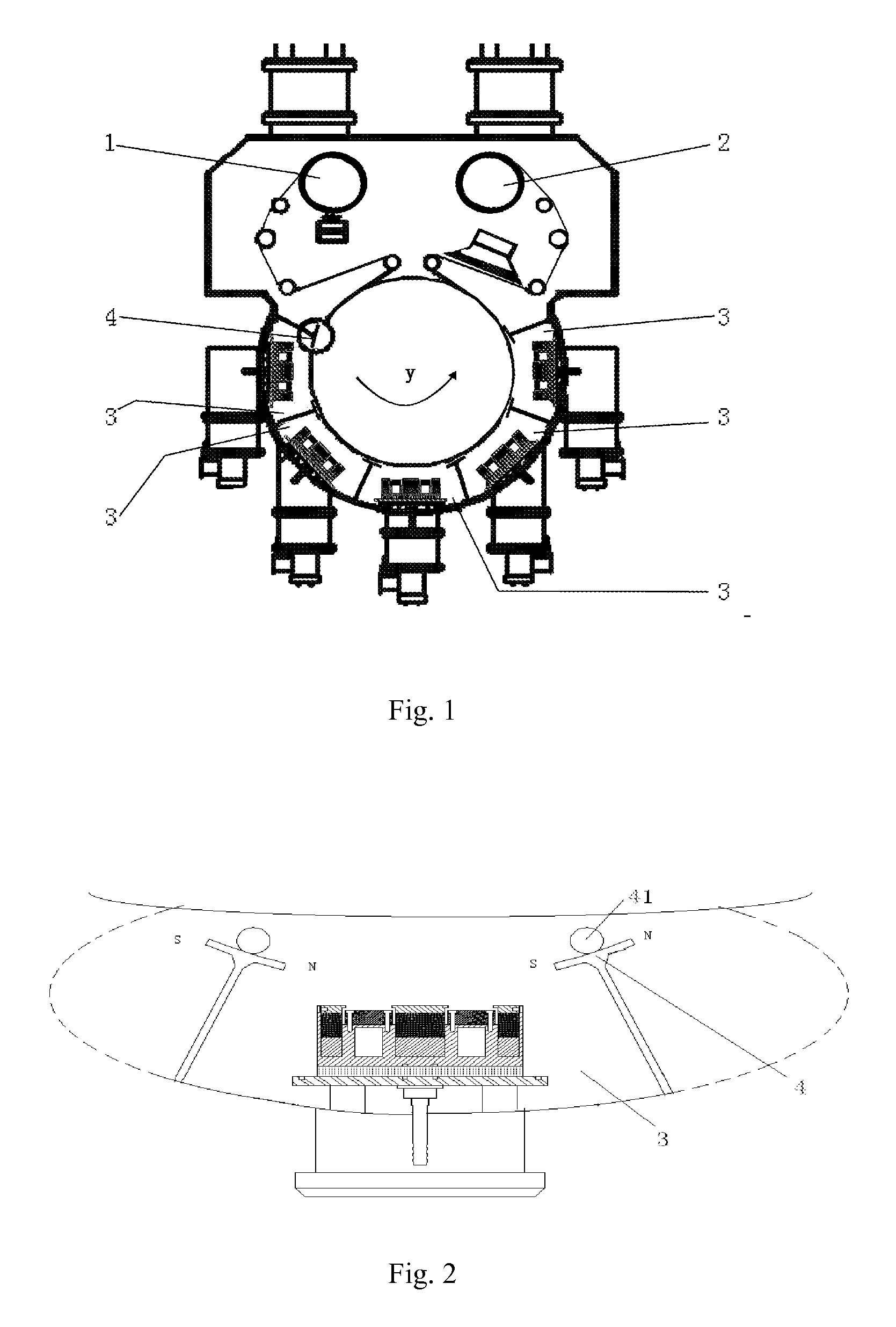

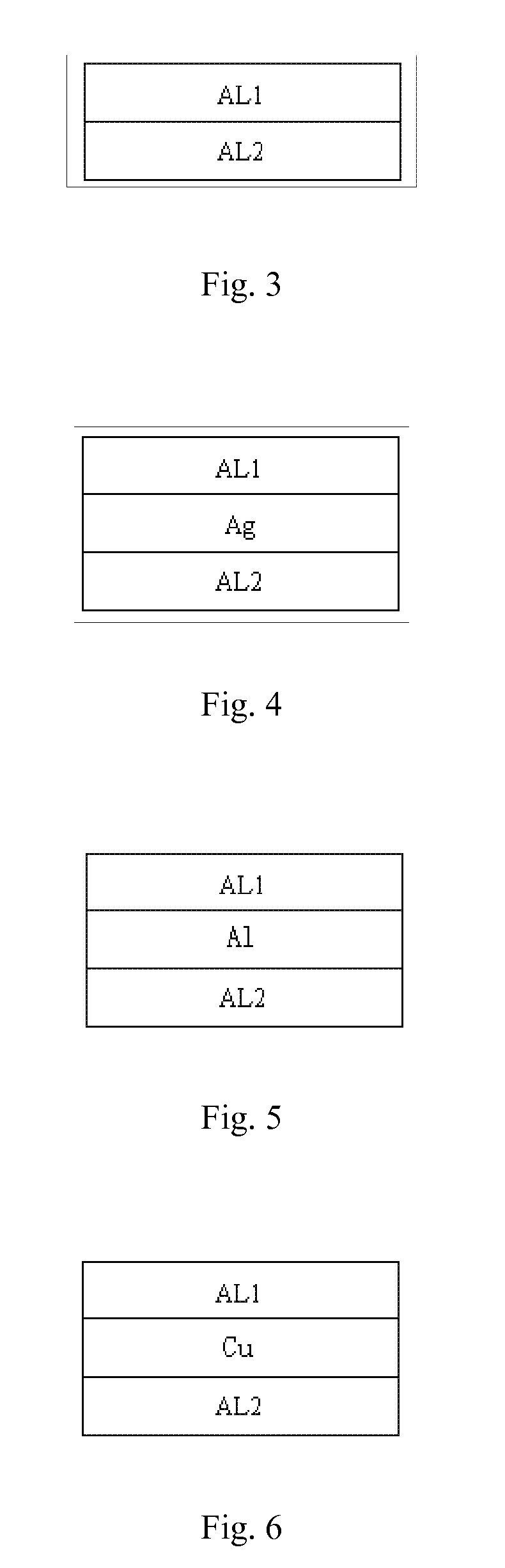

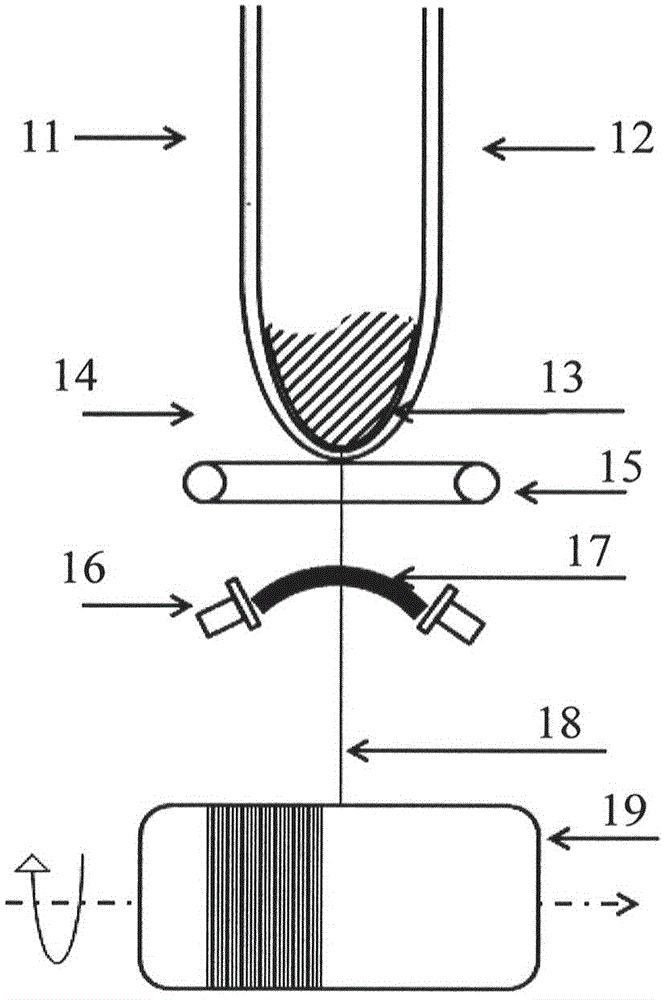

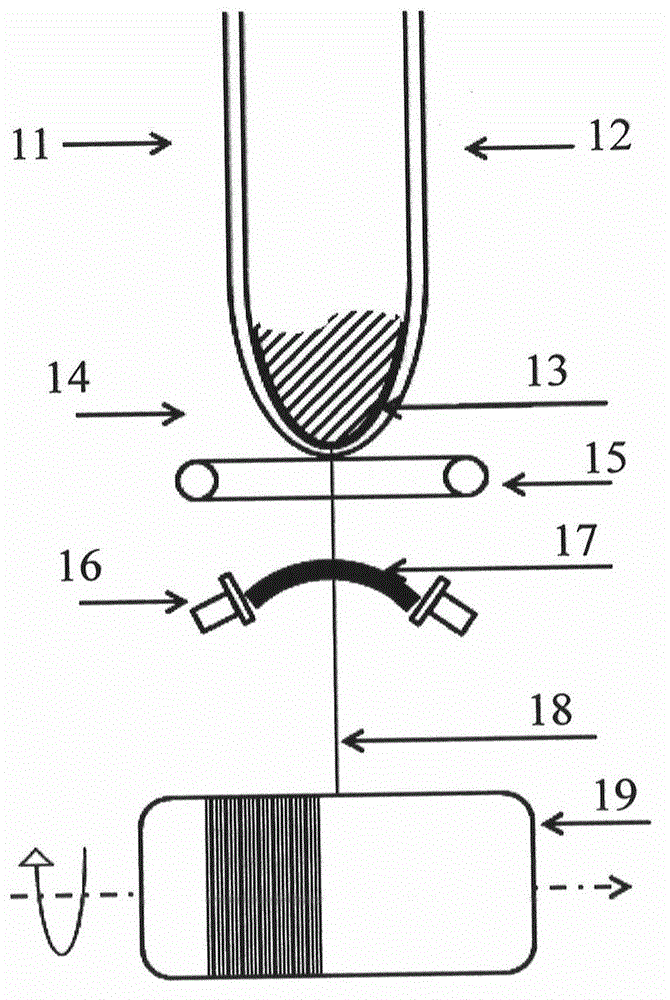

Micro-thrust measurement system based on Barkhausen effect

InactiveCN109632156ASimple structureEasy to operateForce measurement by measuring magnetic property varationElectricityInverse magnetostrictive effect

The invention provides a micro-thrust measurement system based on the Barkhausen effect. According to characteristics of the electric propulsion thrust as well as the inverse magnetostrictive effect (magnetism principle) and the Barkhausen effect, a thruster applies the thrust to a magnetoelastic element and then the change of Barkhausen noises is measured to obtain the change of the internal stress of the magnetoelastic element, so that the magnitude and variation of the thrust are obtained. The a micro-thrust measurement system has advantages of simple structure, great convenience in operation, high reliability, and high detection sensitivity and accuracy; the change of stress is measured in real time; and the small transient thrust of the electric thruster is measured precisely.

Owner:NAT UNIV OF DEFENSE TECH

Recording paper

A recording paper having a magnetic material-containing layer, that includes a magnetic material that generates a large Barkhausen effect and a filler, and is disposed between pulp layers containing a pulp.

Owner:FUJIFILM BUSINESS INNOVATION CORP

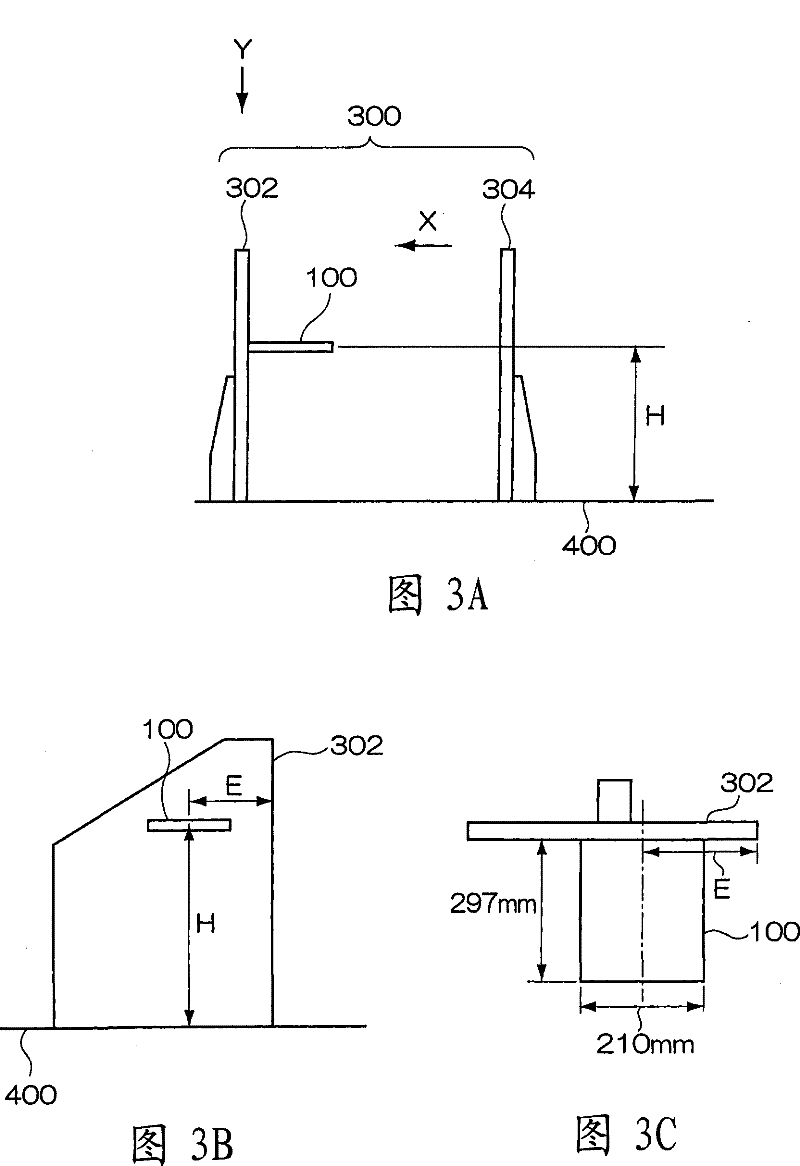

Recording medium detecting system

ActiveCN1991402ANon-fibrous pulp additionMagnetic property measurementsDensity differenceMagnetic flux

A recording medium detecting system includes a magnetic field-generating unit that generates an alternating magnetic field in a predetermined particular region, a detecting unit provided close to the particular region, that detects a change in magnetic flux density not smaller than a predetermined magnetic-flux-density difference B 2 , and a recording medium, containing multiple magnetic wires made of a magnetic material and formed in a wire shape having a predetermined length, that causes a large Barkhausen effect when the alternating magnetic field is applied. A magnetic-flux-density difference B 1 detected by the detecting unit at an installation position thereof when the recording medium is placed in the particular region is not smaller than the magnetic-flux-density difference B 2 .

Owner:FUJIFILM BUSINESS INNOVATION CORP

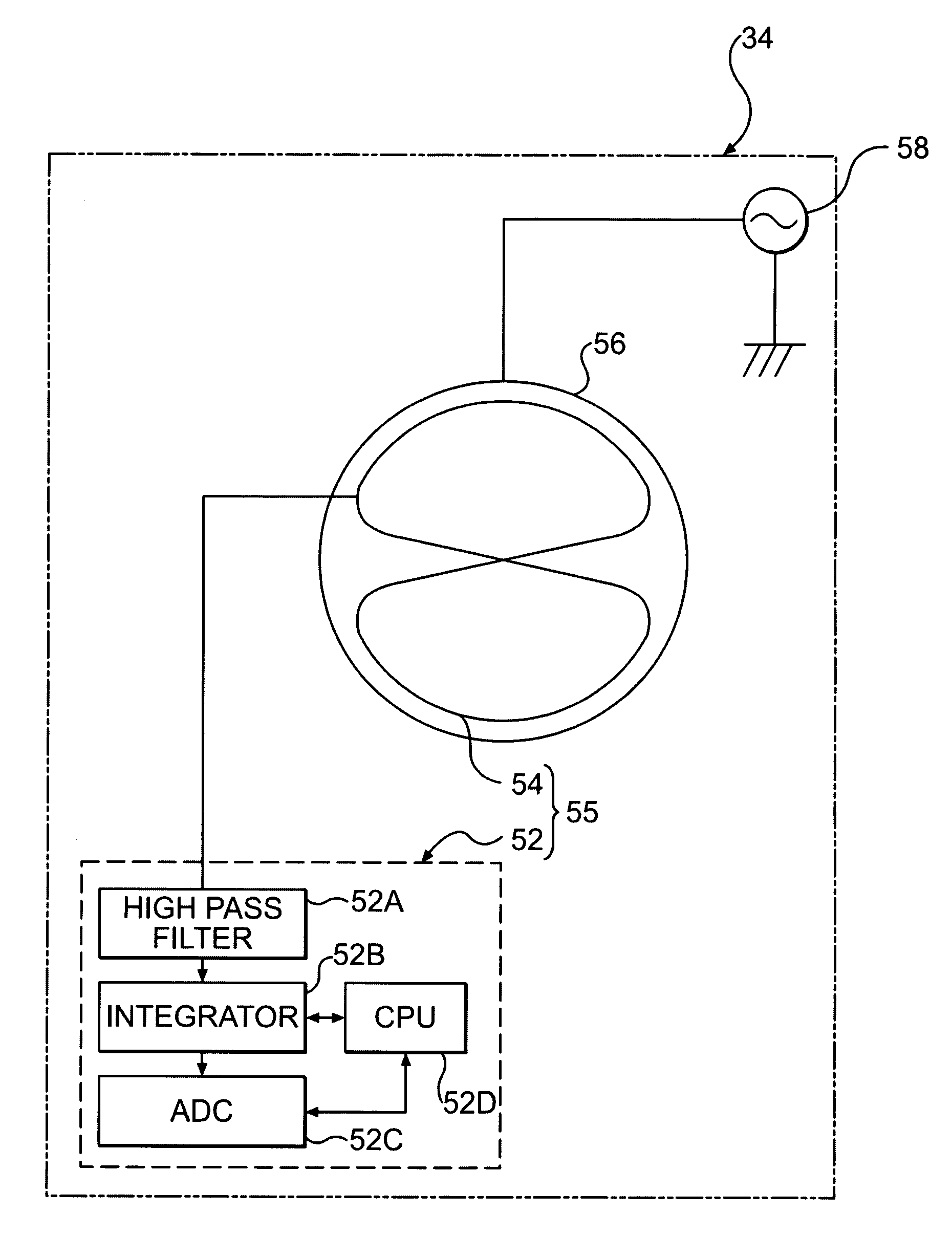

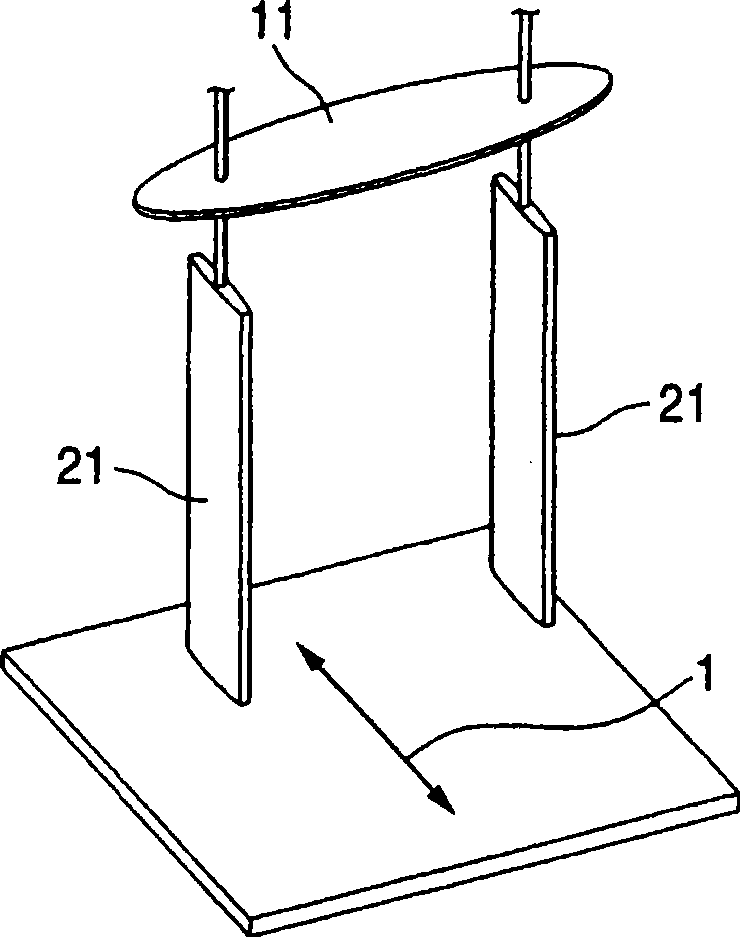

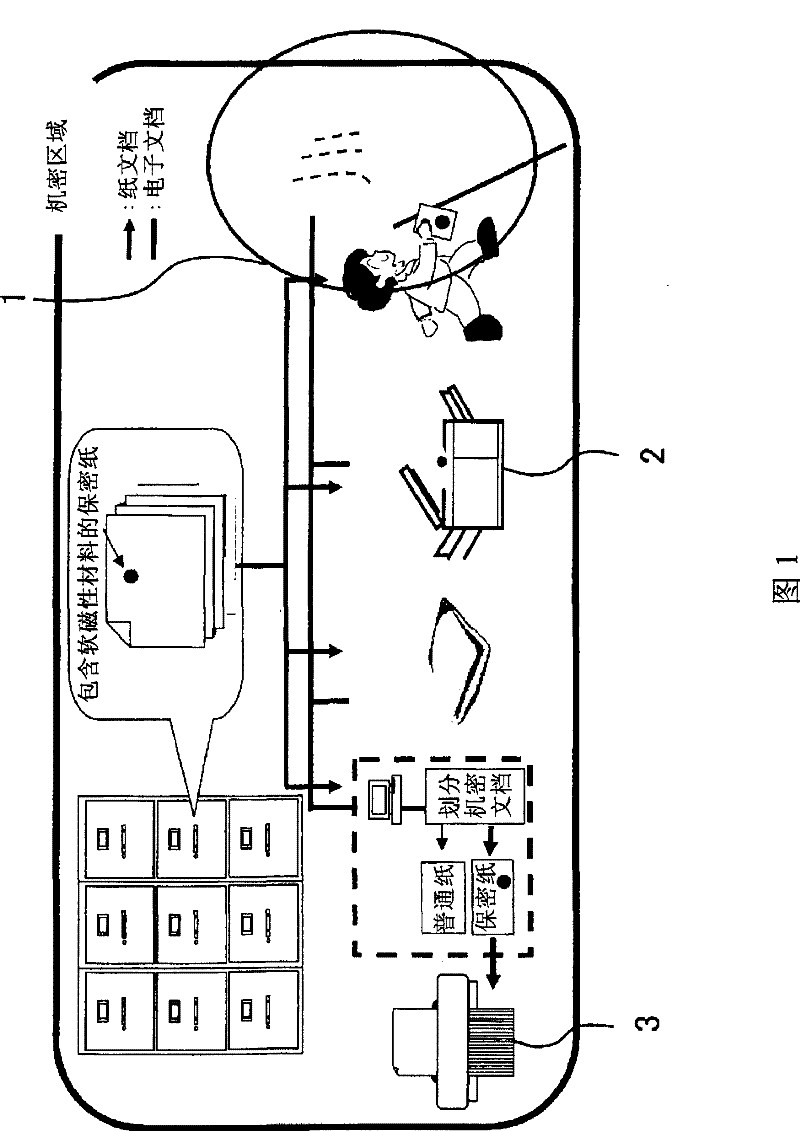

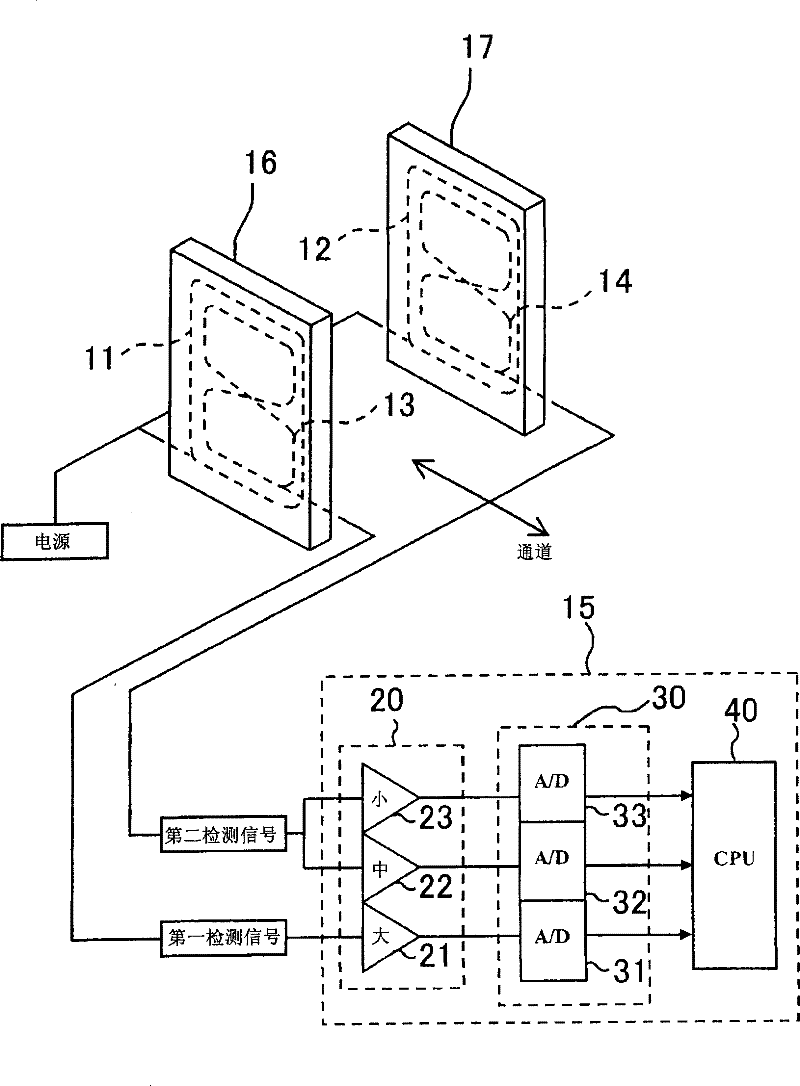

Baggage management gate

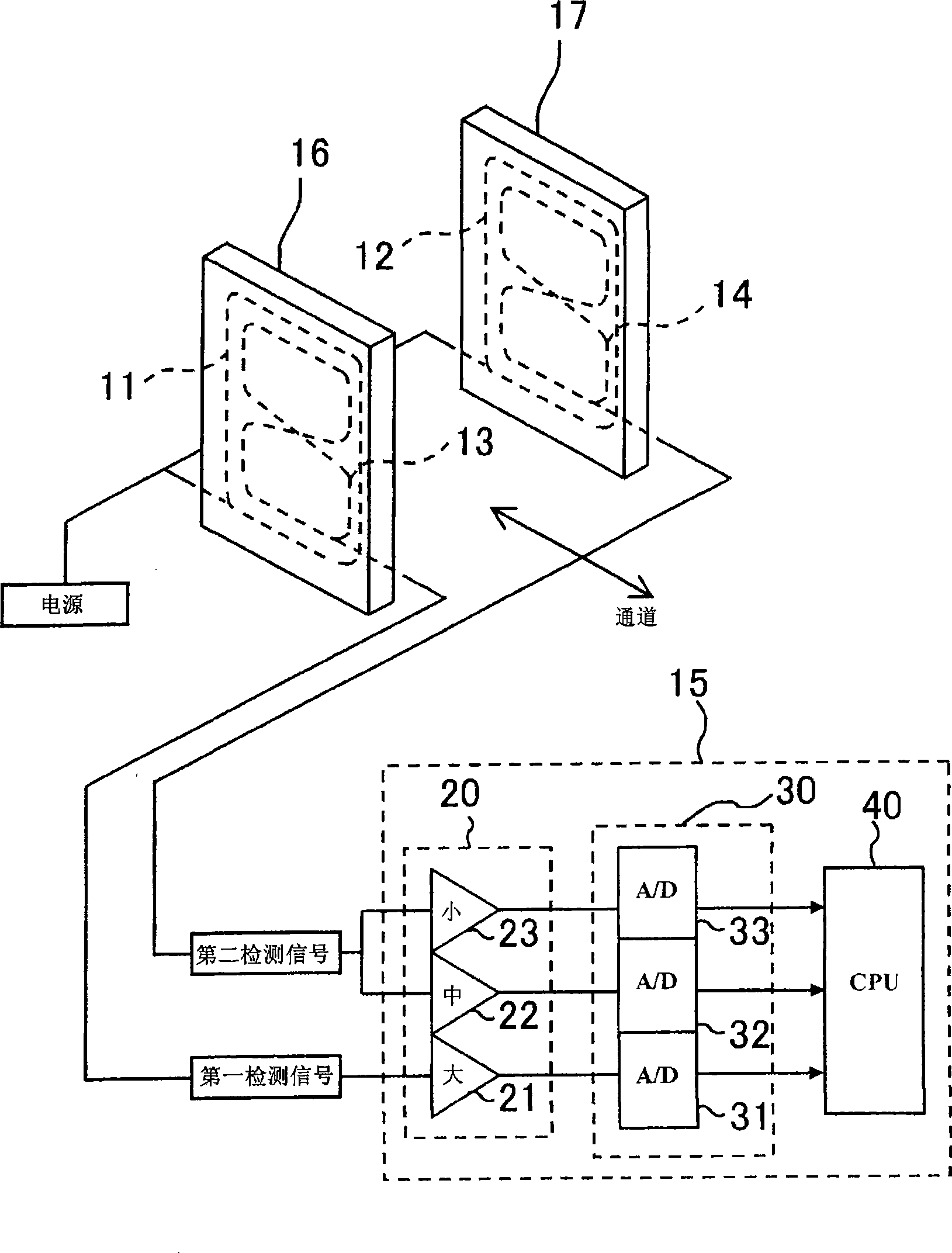

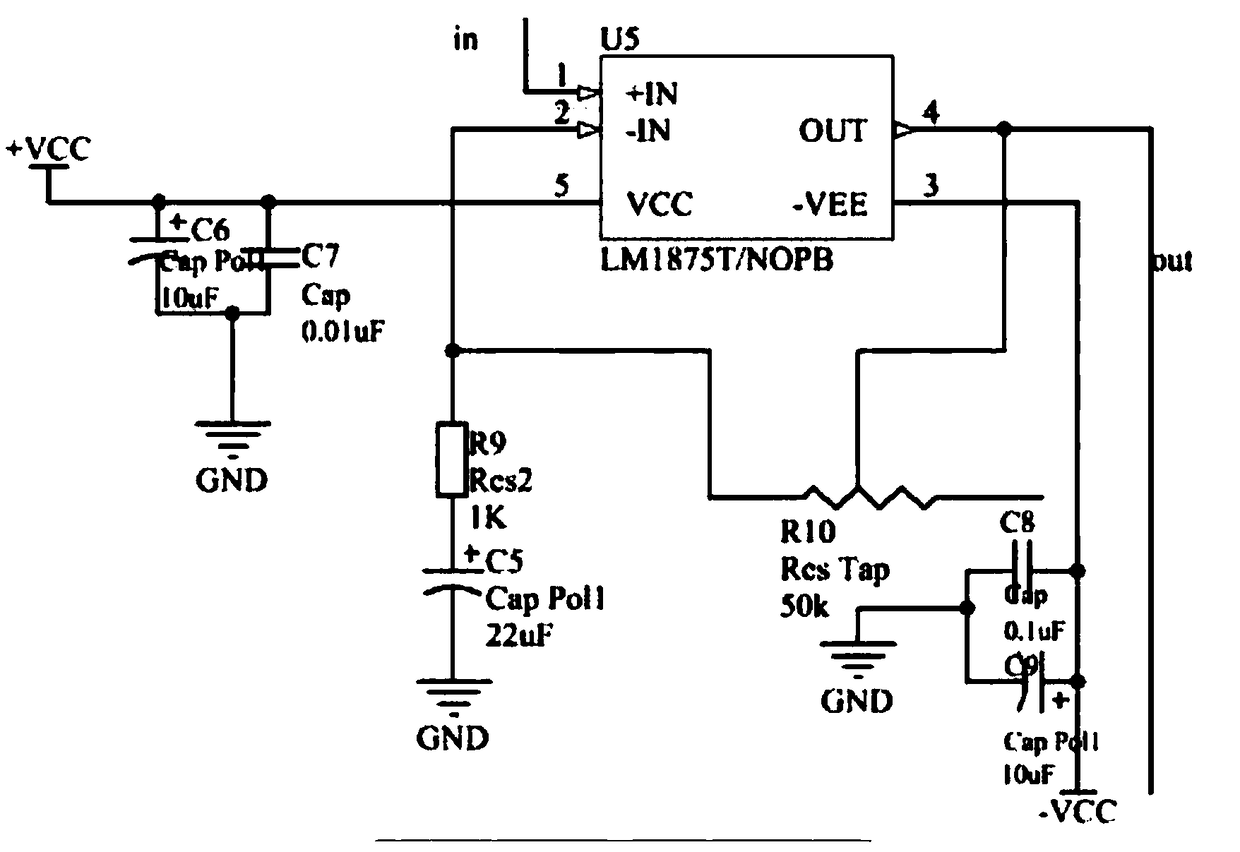

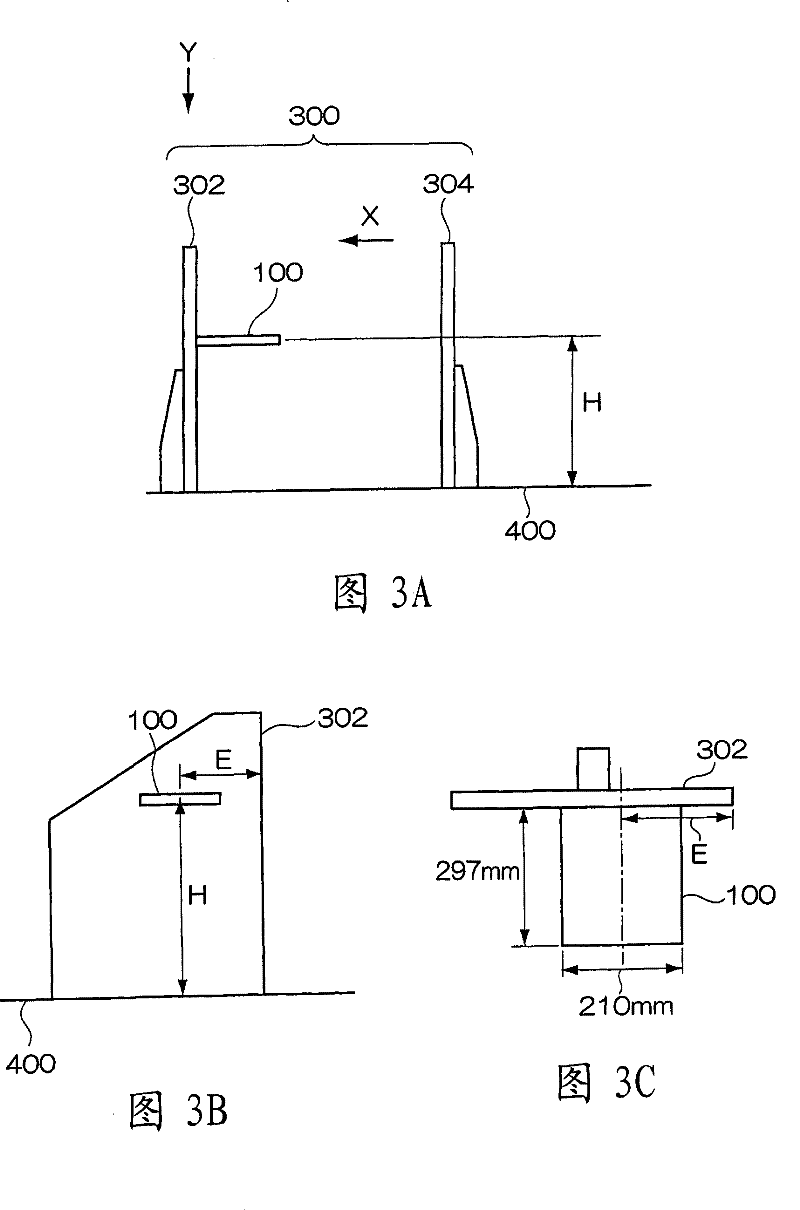

ActiveCN101393253AImprove detection accuracyImprove S/N ratioMagnetic field measurement using flux-gate principleBurglar alarm electric actuationAudio power amplifierManaged object

A baggage management gate including an exciting coil, a detecting coil and signal processing unit. The exciting coil forms an alternating magnetic field in a passage to an area from which manages objects to be carried in or carried out. The detecting coil detects a variation in the alternating magnetic field when magnetization of a magnetic material showing a large Barkhausen effect is reversed in the alternating magnetic field. The signal processing unit determines as to whether the magnetization reversal occurs in the alternating magnetic field due to the large Barkhausen effect or not, based on a signal detected by the detecting coil. The signal processing unit includes amplifier that amplifies the signal detected by the detecting coil with plural different amplification factors and output the amplified signals with each of the plural different amplification factors.

Owner:FUJIFILM BUSINESS INNOVATION CORP

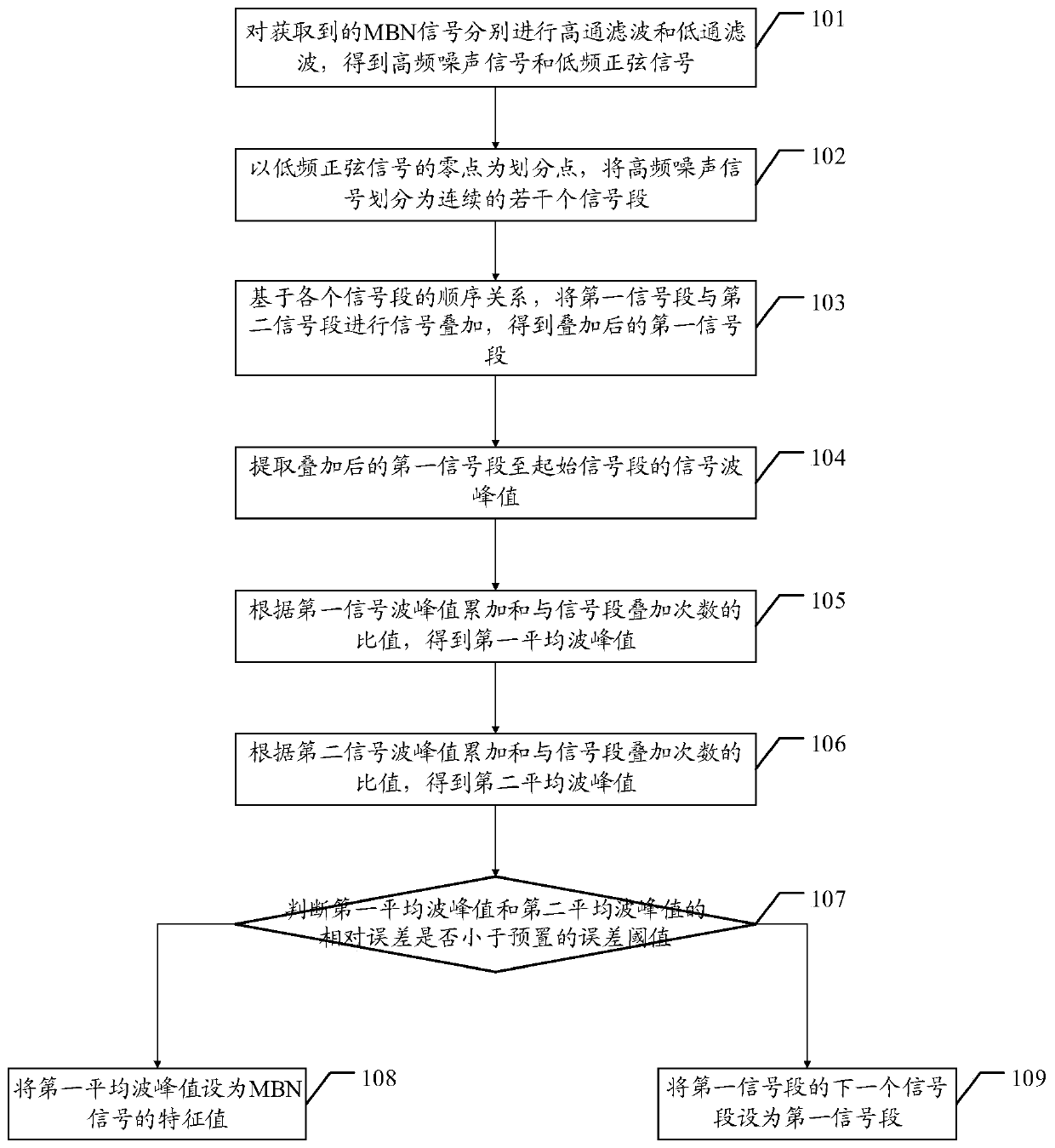

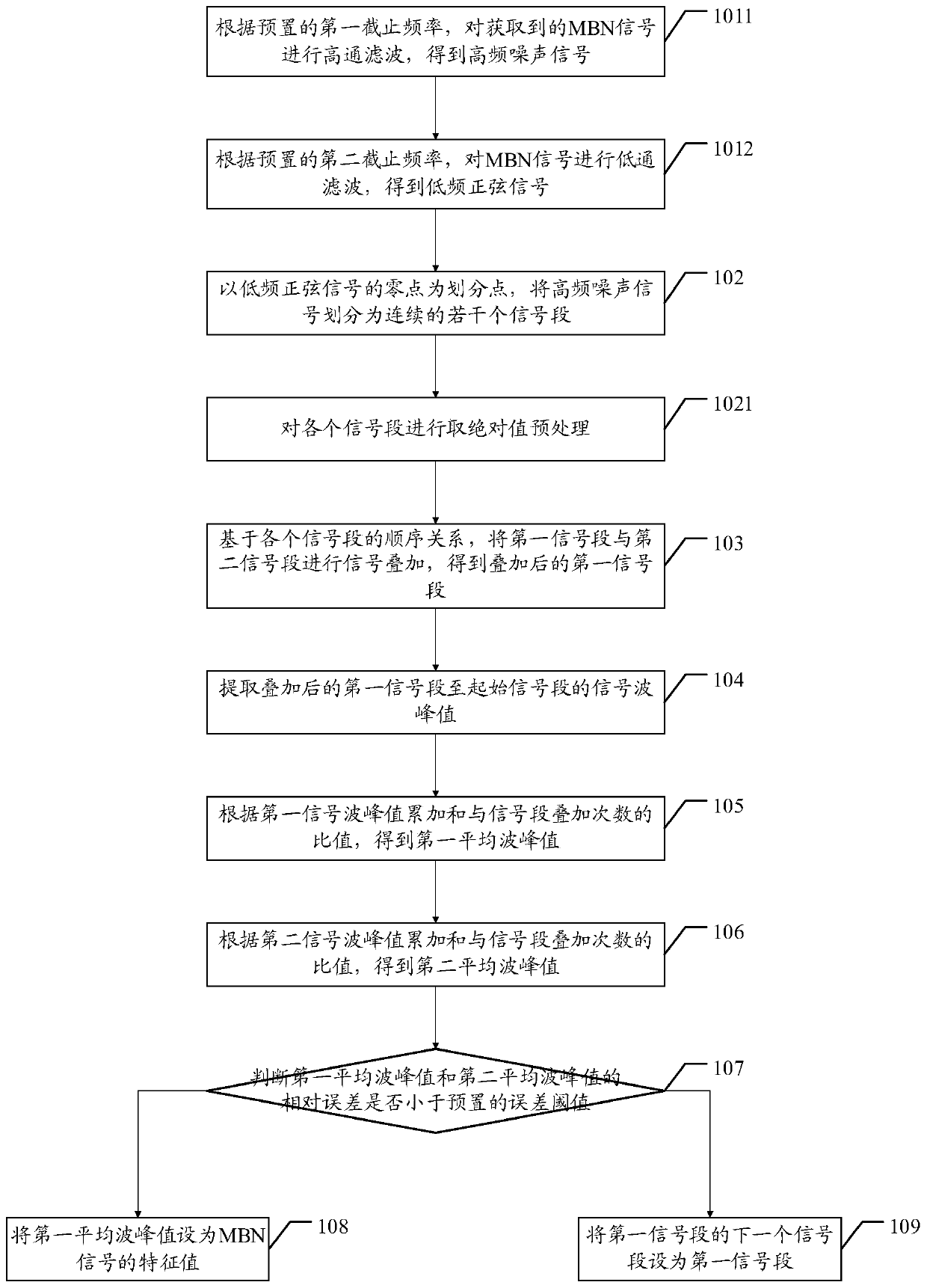

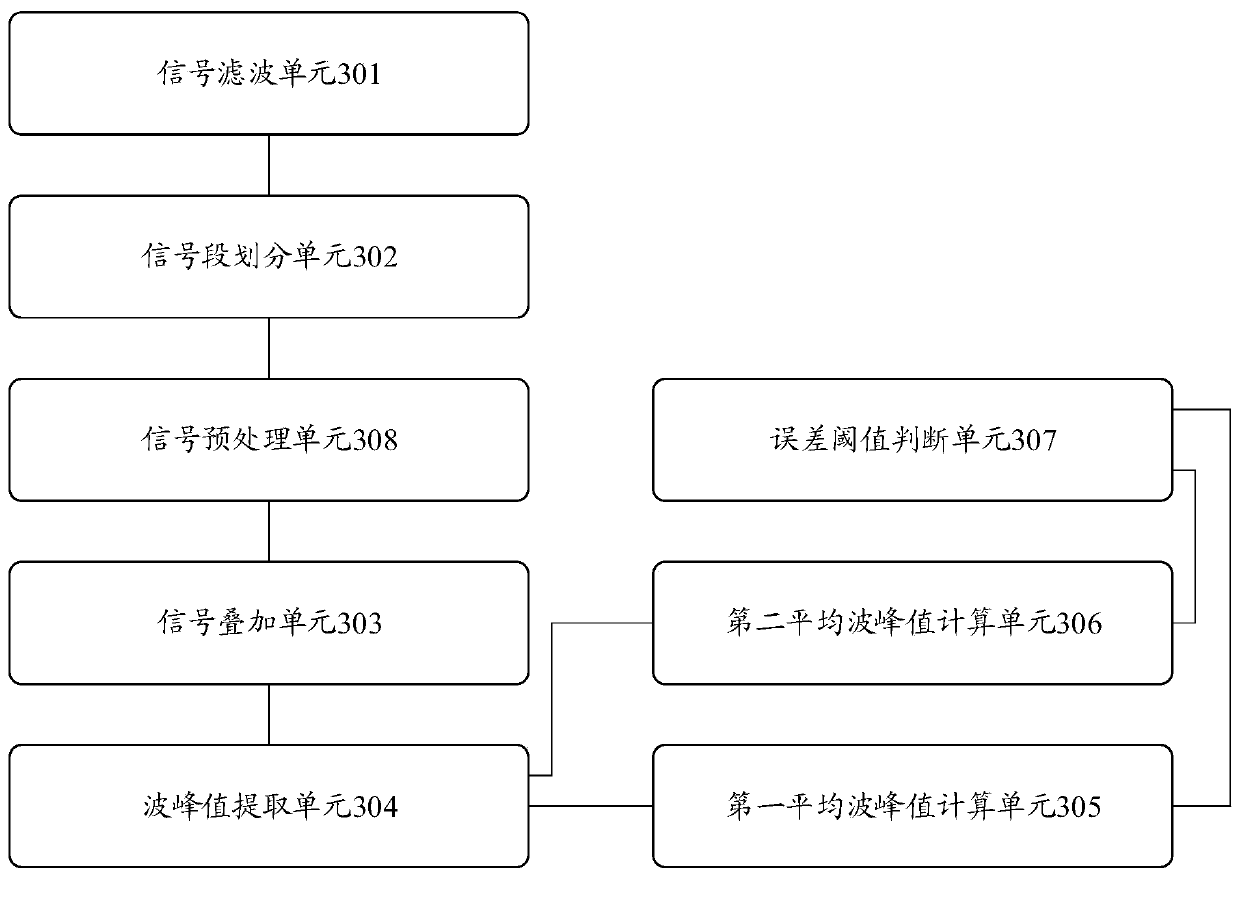

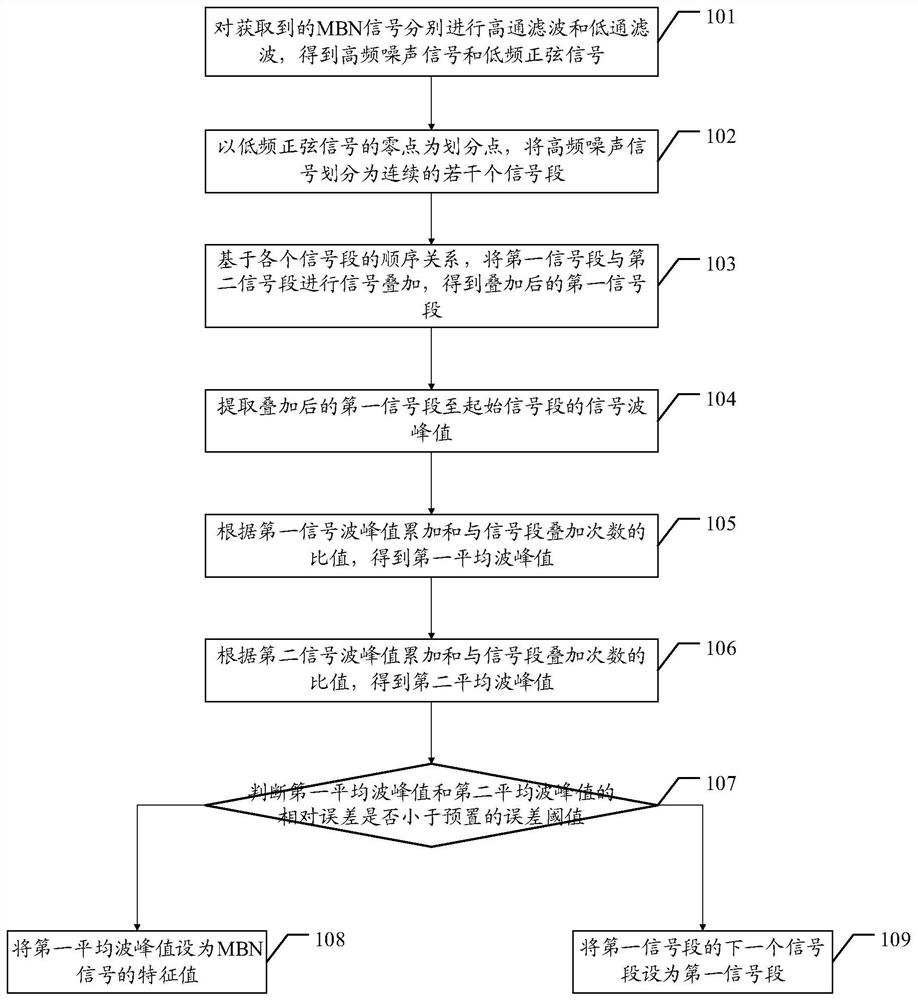

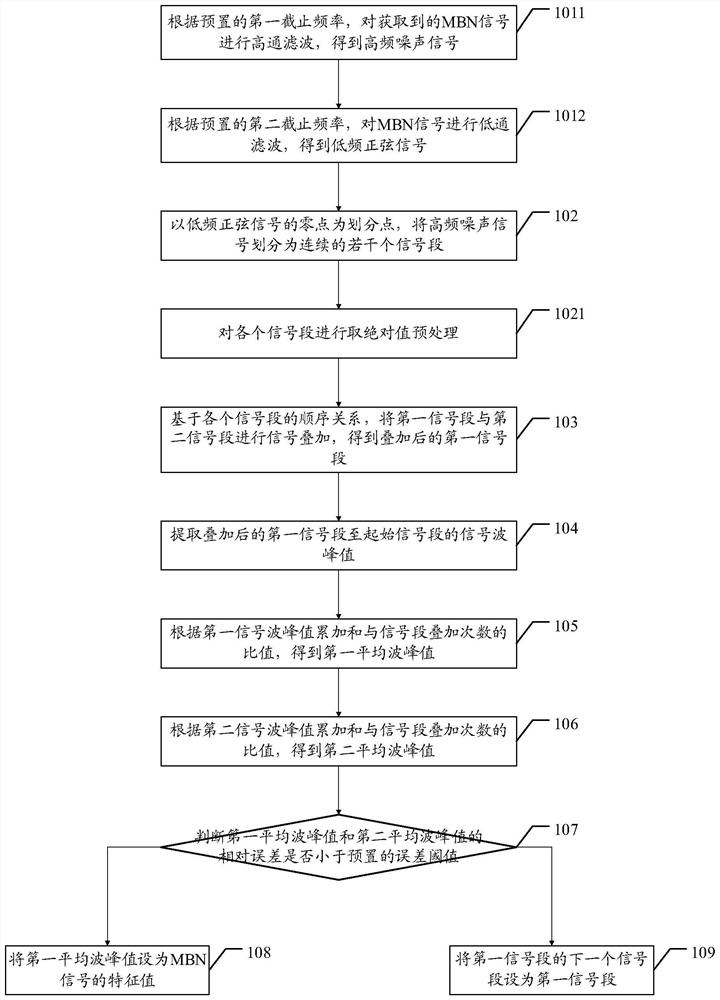

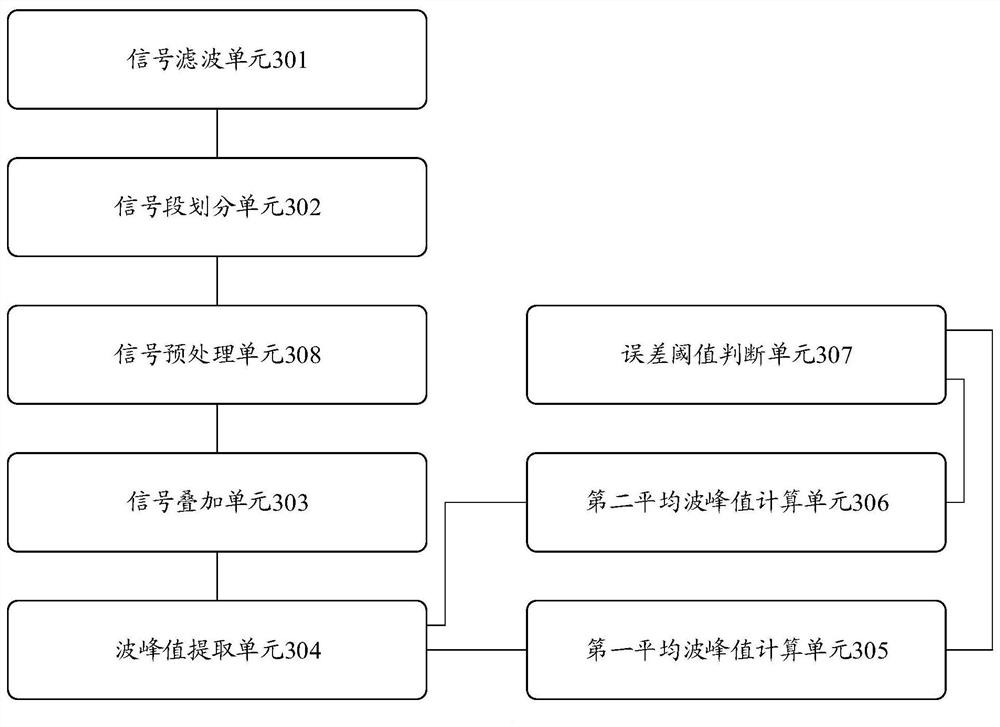

Barkhausen signal characteristic acquisition method and device, terminal and storage medium

ActiveCN110388996AImprove accuracySmooth peaks and sharp fluctuationsForce measurement by measuring magnetic property varationApparatus for force/torque/work measurementComputer terminalComputer science

The invention discloses a Barkhausen signal characteristic acquisition method and device, a terminal and a storage medium. The method comprises the following steps: dividing a high-frequency noise signal into multiple signal segments based on the zero point of a low-frequency sine signal, performing signal superposition on the adjacent signal segments and performing superposition meaning on a signal crest value, wherein the crest drastic fluctuation caused by the randomness of the noise signal is smoothened, thereby improving the accuracy of the characteristic value extraction, and then improving the accuracy of the stress test. And the technical problem that the existing Barkhausen effect is large in stress testing error is solved.

Owner:GUANGDONG POWER GRID CO LTD +1

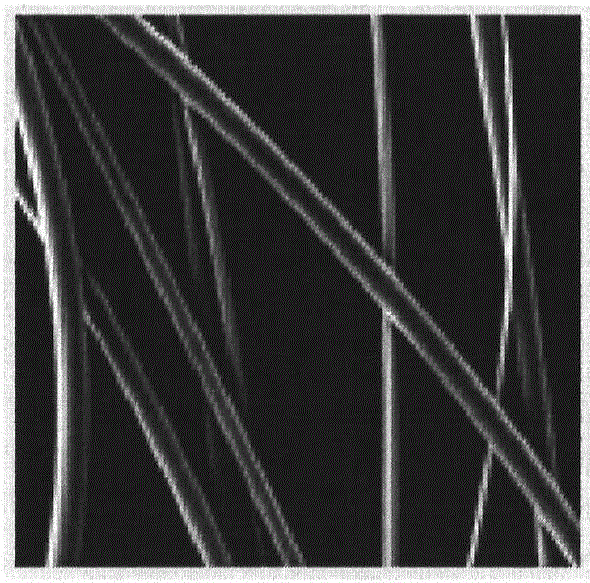

Memory with anti-theft function

InactiveCN106328180AImprove anti-theftImprove vandal resistanceDigital storageComputer hardwareFiber

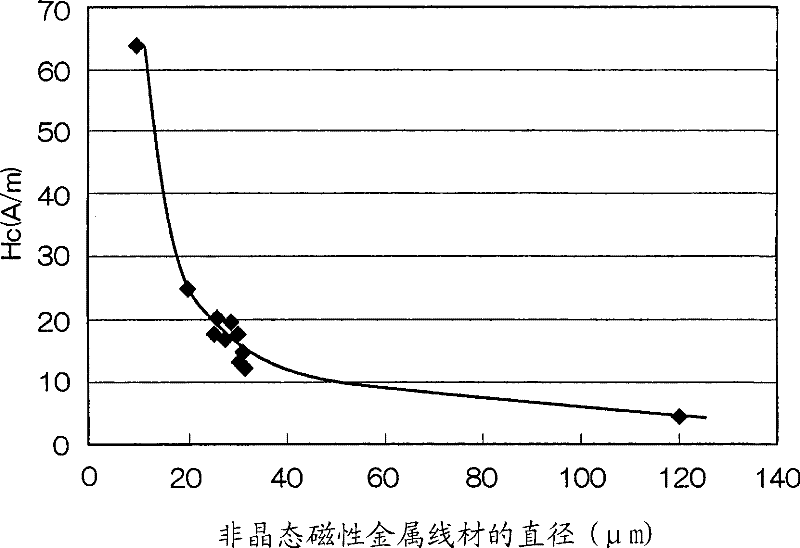

The present invention relates to a memory with an anti-theft function, and a method preparing the memory with the anti-theft function. An amorphous fiber with the Great Barkhausen effect is embedded in the memory with the anti-theft function, wherein the diameter of the amorphous fiber is 10-150 micron, preferably 20-30 micron, and the length of the amorphous fiber is 2-15mm, 3-8mm, or 3-5mm.

Owner:BEIJING HENGWEI TECH CO LTD +2

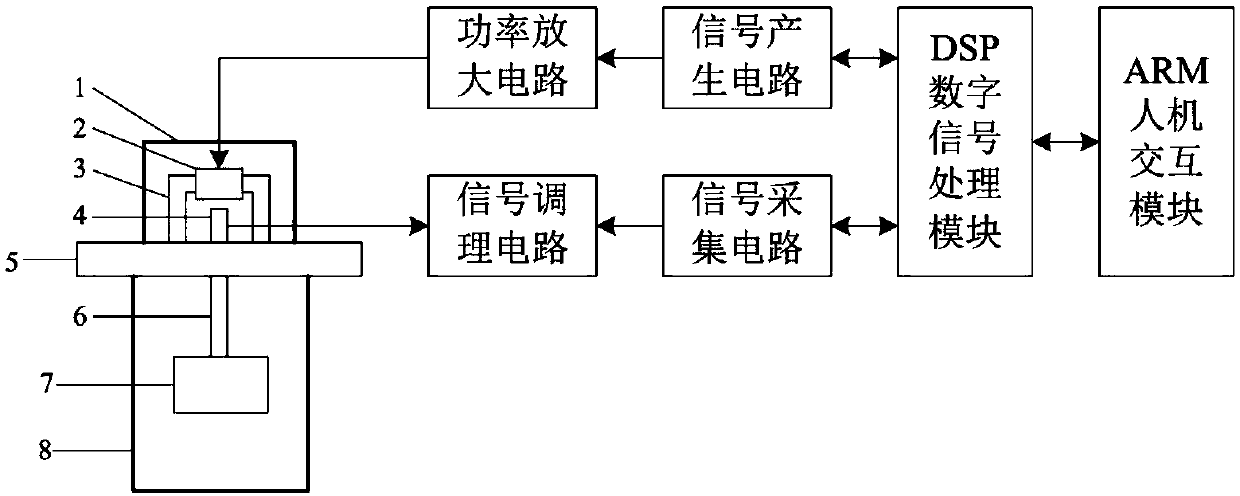

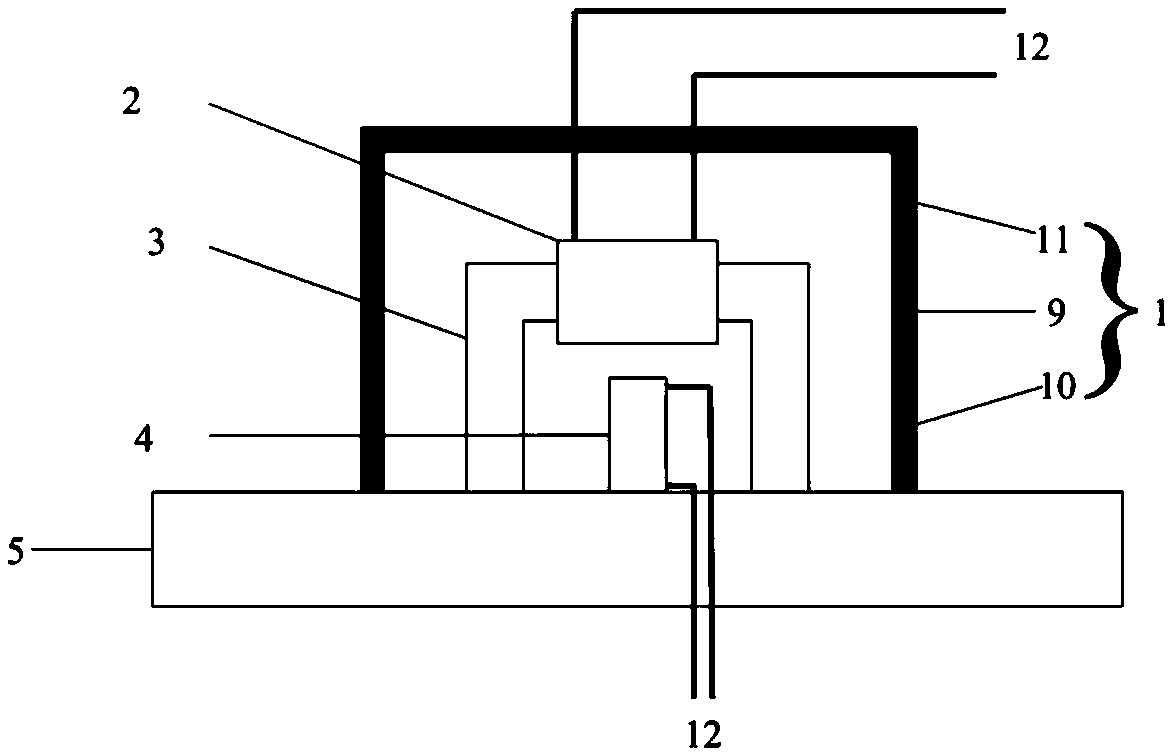

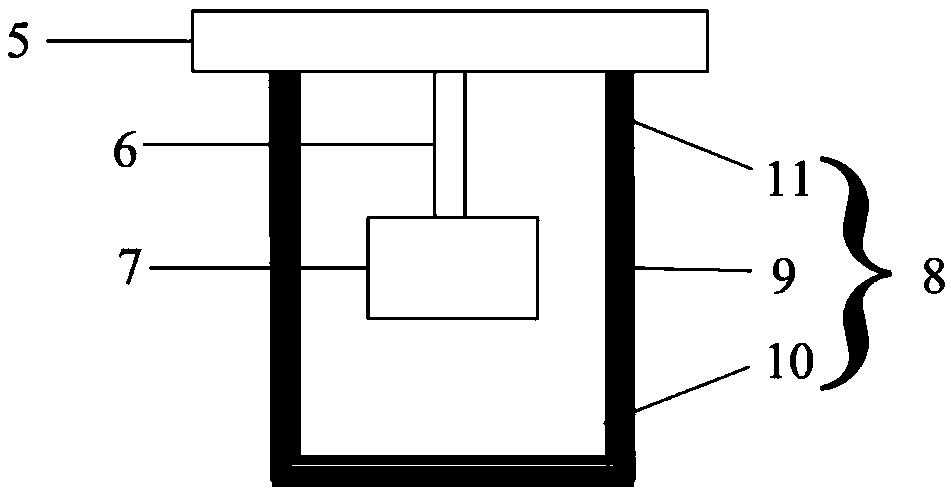

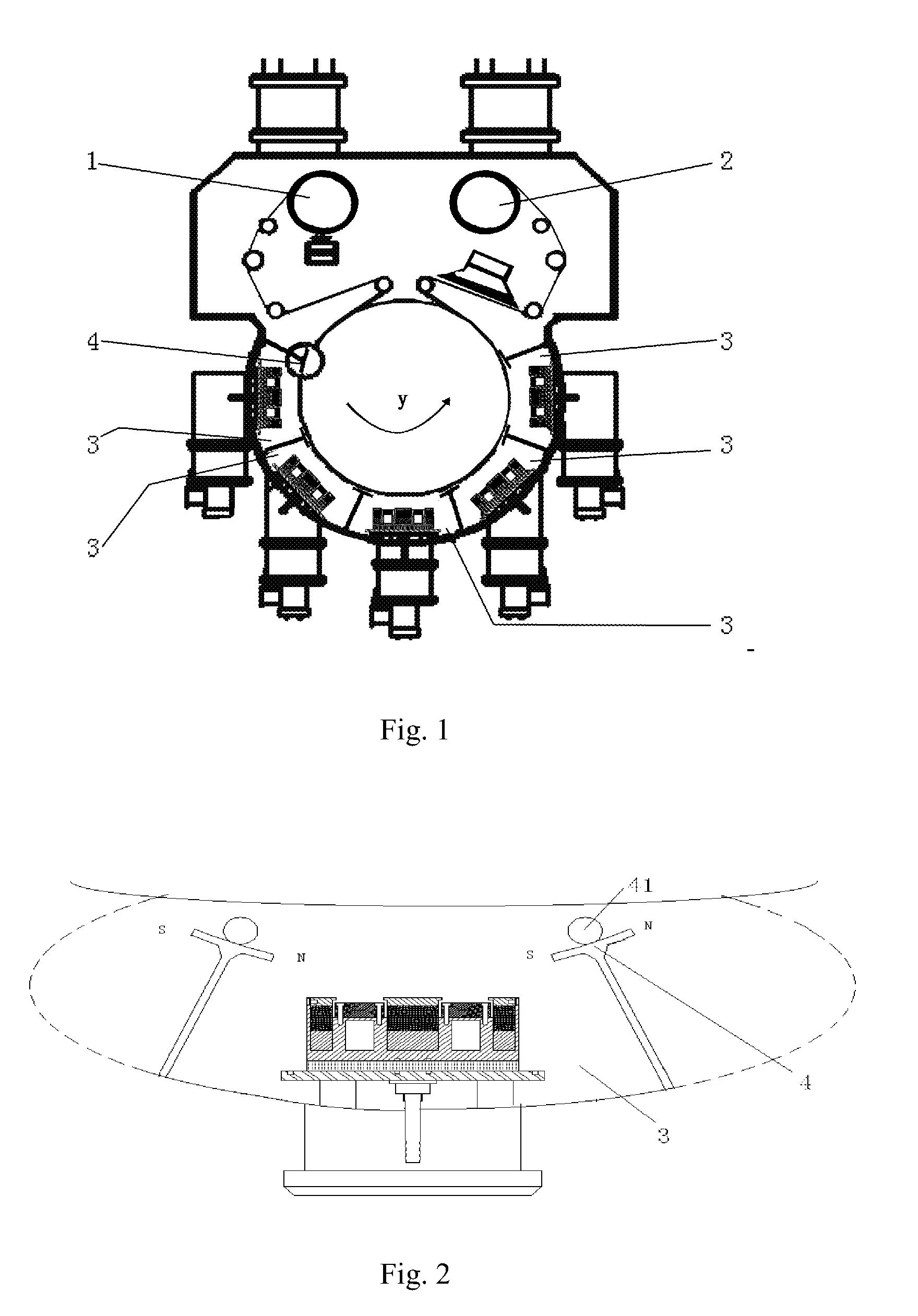

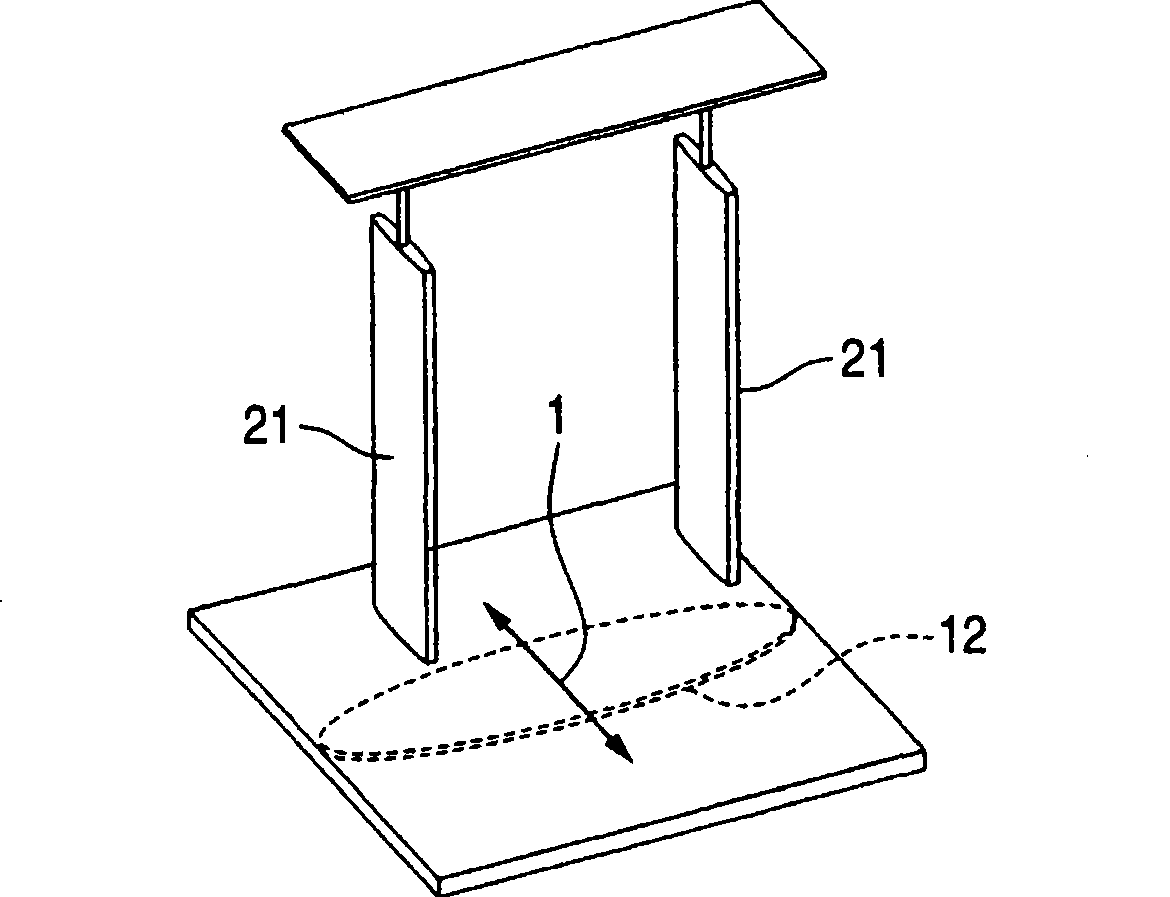

Barkhausen effect-based numerically controlled machine tool triangular track flaw detection system

InactiveCN109507279ARealize online detectionOvercoming lift-offMaterial magnetic variablesFatigue damageNumerical control

The invention discloses a Barkhausen effect-based numerically controlled machine tool triangular track flaw detection system, which utilizes a Barkhausen noise signal detection principle to detect a machine tool track on line. Two detection probes which are fixed at the end part of a center rest of a machine tool are utilized to respectively detect two tracks in real time, detection information istransmitted to an external upper computer by the way of wireless communication, and the upper computer can judge whether problems, such as internal cracks, plastic deformation and fatigue damage, exist in the tracks according to the detection information. The whole structure of each detection probe is V-shaped, one side of each detection probe is provided with a magnetizing coil and an iron coreconnected through a spring and wound by a detection coil, an iron core connected through the spring on the other side forms a V-shaped included angle with the iron core wound by the detection coil, the detection probes can clamp the two sides of the to-be-detected triangular tracks of a machine tool under the action of the springs, and therefore the situation that the detection probes are lifted off in a process of detection based on a Barkhausen effect can be overcome.

Owner:南京美克斯精密机械有限公司

Security functional thin film and security product containing the functional thin film

ActiveUS8257840B2Improve security featuresNon-fibrous pulp additionNatural cellulose pulp/paperIn planeOptoelectronics

Owner:CHINA BANKNOTE PRINTING & MINTING

Antitheft safety paper

The invention relates to antitheft safety paper and a preparation method thereof. Particularly, noncrystalline fiber with is implanted in the antitheft safety paper, and diameter of the noncrystalline fiber is 10-50 micronmeters and 20-30 micrometers preferably while length of the same is 2-10mm or 3-8mm or 3-5mm.

Owner:BEIJING HENGWEI TECH CO LTD

Anti-theft safety paper

The invention relates to anti-theft safety paper. Non-crystal naked fibers having a big barkhausen effect are planted in the anti-theft safety paper, wherein the diameter of the non-crystal naked fibers is 10-50 microns, preferably 20-30 microns; and the length of the non-crystal naked fibers is 2-10mm, or 3-8mm, or 3-5mm.

Owner:BEIJING HENGWEI TECH CO LTD

Magnetic wire and recording media

The present invention provides a magnetic wire and a recording medium. The magnetic wire includes a magnetic metal wire, and the surface of the magnetic metal wire is covered with an insulating material layer. The magnetic wire has a coercive force of 30 A / m or less and has a Barkhausen effect.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Control gate

InactiveCN101392618AReduce the impactLightweight and compactPower-operated mechanismBank protection deviceVertical planeAcoustics

A control gate, including an exciting coil and a detecting coil, is disclosed. The exciting coil forms an alternating magnetic field in a passageway at an entrance to or an exit from an area where taking out or bringing in of an object is controlled. The detecting coil detects a change of the magnetic field when magnetic substance contained in the object generating a large Barkhausen effect causes magnetic inversion in the alternating magnetic field. The exciting coil is provided above the passageway and has a winding wire wound along a horizontal plane. The detecting coil is provided in a side part of the passageway and has a winding wire wound along a vertical plane which is parallel to a passing direction of the passageway.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Anti-theft safety paper

The invention relates to anti-theft safety paper and a method for preparing the anti-theft safety paper, and provides the anti-theft safety paper. Non-crystal fibers having a big barkhausen effect are planted in the anti-theft safety paper, wherein the diameter of the non-crystal fibers is 80-200 microns, preferably 100-150 microns; and the length of the non-crystal fibers is 2-10mm.

Owner:BEIJING HENGWEI TECH CO LTD

A Barkhausen signal feature acquisition method, device, terminal and storage medium

ActiveCN110388996BImprove accuracySmooth peaks and sharp fluctuationsForce measurement by measuring magnetic property varationApparatus for force/torque/work measurementSignal waveComputer science

A Barkhausen signal feature acquisition method, device, terminal and storage medium. In this application, the high-frequency noise signal is divided into multiple signal segments by using the zero point of the low-frequency sinusoidal signal, and the peaks caused by the randomness of the noise signal are smoothed by superimposing adjacent signal segments and superimposing and averaging the signal peaks Vigorous fluctuations, thereby improving the accuracy of feature value extraction, thereby improving the accuracy of stress testing, and solving the existing technical problem of large errors in stress testing based on the Barkhausen effect.

Owner:GUANGDONG POWER GRID CO LTD +1

Transfer paper for electrophotography

ActiveCN101265679BDetection accuracy dropsInhibition of prominenceSpecial paperDryer sectionFiberMoisture

A transfer paper for electrophotography contains a pulp fiber and a magnetic material for generating a large Barkhausen effect. An average dehydration speed S 1 a (an average value (% by mass / second) of dehydration speeds S 1 of 5 sheets of paper) is 0.15 or less. The dehydration speed S 1 is represented by (W 1 a-W 1 b) / 30. Here, W 1 a represents a moisture content ratio (% by mass) of the paperafter moisture conditioning, and W 1 b represents a moisture content ratio (% by mass) of the paper after a dehydration process including leaving the paper in a 80 DEG C. environment for 30 seconds after moisture conditioning.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Baggage management gate

ActiveCN101393253BAvoid sureThe smallest unit is reducedMagnetic field measurement using flux-gate principleBurglar alarm electric actuationCondensed matter physicsSignal processing

A baggage management gate including an exciting coil, a detecting coil and signal processing unit. The exciting coil forms an alternating magnetic field in a passage to an area from which manages objects to be carried in or carried out. The detecting coil detects a variation in the alternating magnetic field when magnetization of a magnetic material showing a large Barkhausen effect is reversed in the alternating magnetic field. The signal processing unit determines as to whether the magnetization reversal occurs in the alternating magnetic field due to the large Barkhausen effect or not, based on a signal detected by the detecting coil. The signal processing unit includes amplifier that amplifies the signal detected by the detecting coil with plural different amplification factors and output the amplified signals with each of the plural different amplification factors.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Defect and stress non-destructive testing system and non-destructive testing method based on pulsed eddy current and Barkhausen

ActiveCN104977352BDetect structurally different defectsQuantitative detection of structurally diverse defectsMaterial magnetic variablesData acquisitionMicroscopic scale

The invention provides a defect and stress non-destructive detection system and non-destructive detection method based on pulsed eddy current and Barkhausen, belonging to the field of non-destructive detection. The system includes an excitation signal generator, a digital-to-analog converter, a power amplifier, an excitation coil, a Hall sensor, a signal amplification circuit, a data acquisition card and a computer. On the basis of eddy current detection, the present invention uses a mixed wave of a rectangular wave and a triangular wave as an excitation signal for ferromagnetic materials. The rectangular wave band in the first half of the mixed signal produces a pulse eddy current phenomenon, and the triangular wave band in the second half produces a Barkhausen effect. , use the signal time domain averaging method to process the signal in segments, realize the separation of the eddy current signal and the Barkhausen noise signal, and extract the feature and data processing of the signal separately, so as to realize the simultaneous online detection of the surface defects, stress and microstructure state of ferromagnetic materials , and realize the identification of hidden defects of ferromagnetic materials and the prediction of unformed defects and life. The invention can work reliably for a long time, has high sensitivity, simple method, intuitive display, high efficiency and feasibility, and the like.

Owner:江苏高特高金属科技有限公司

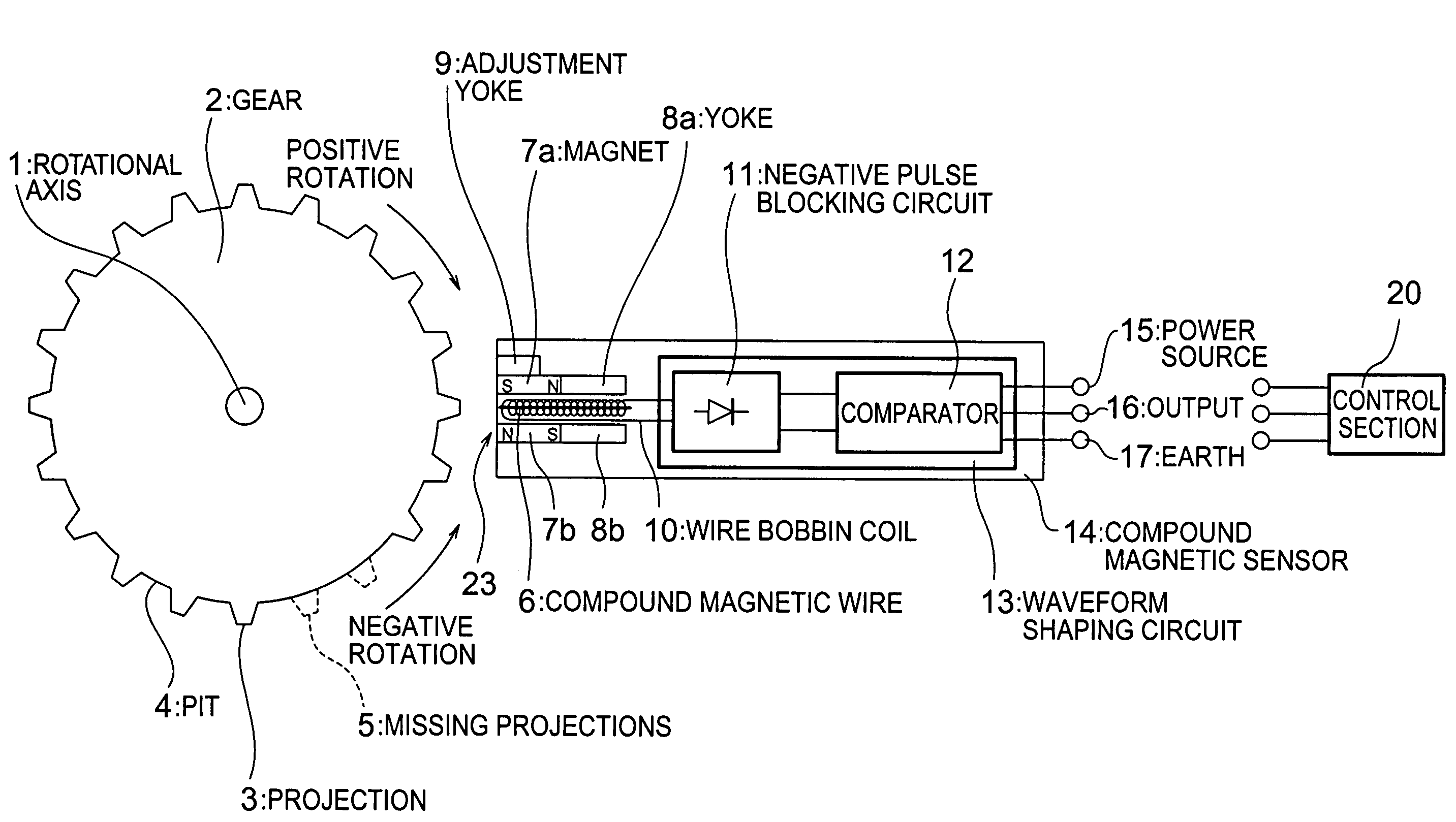

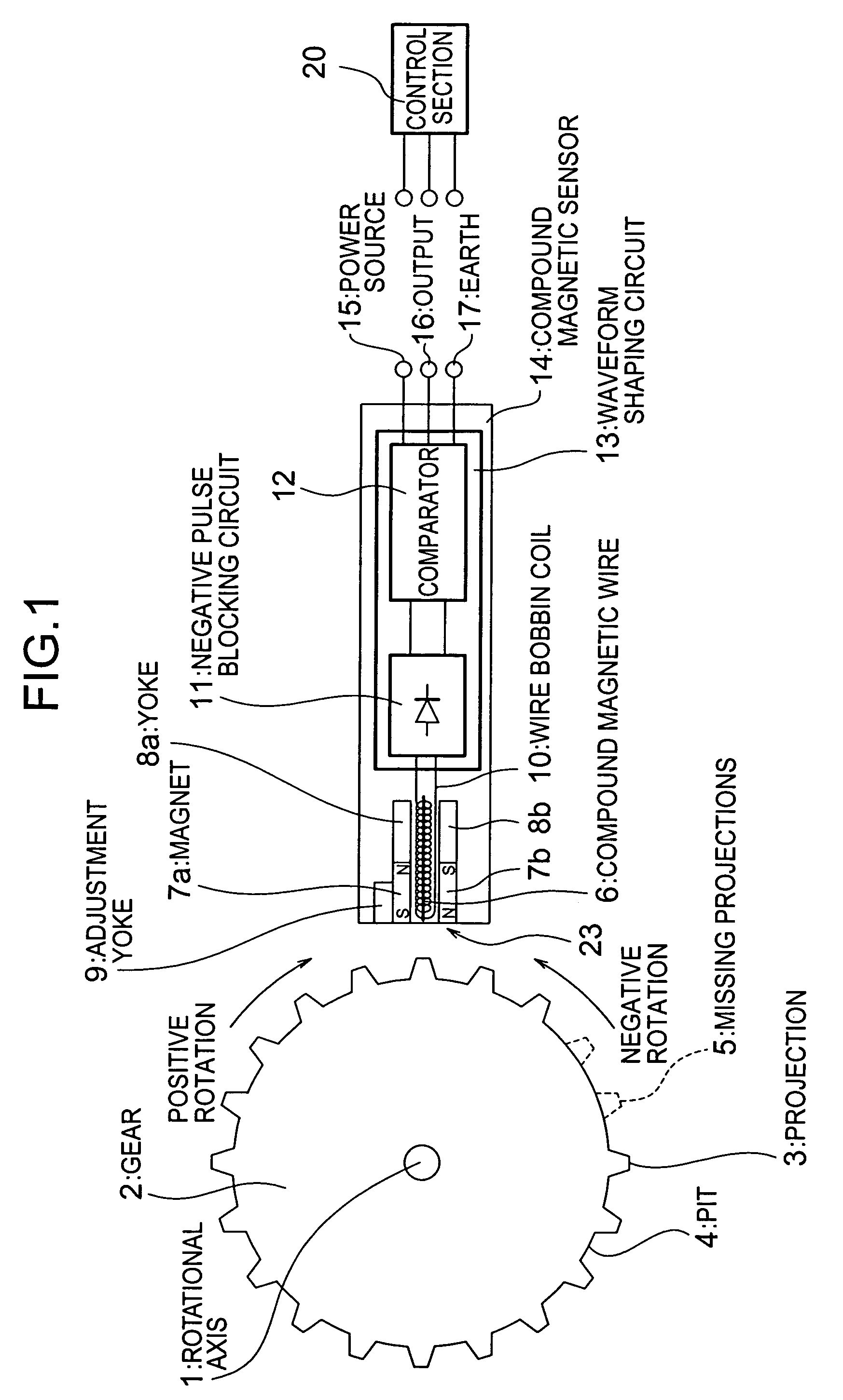

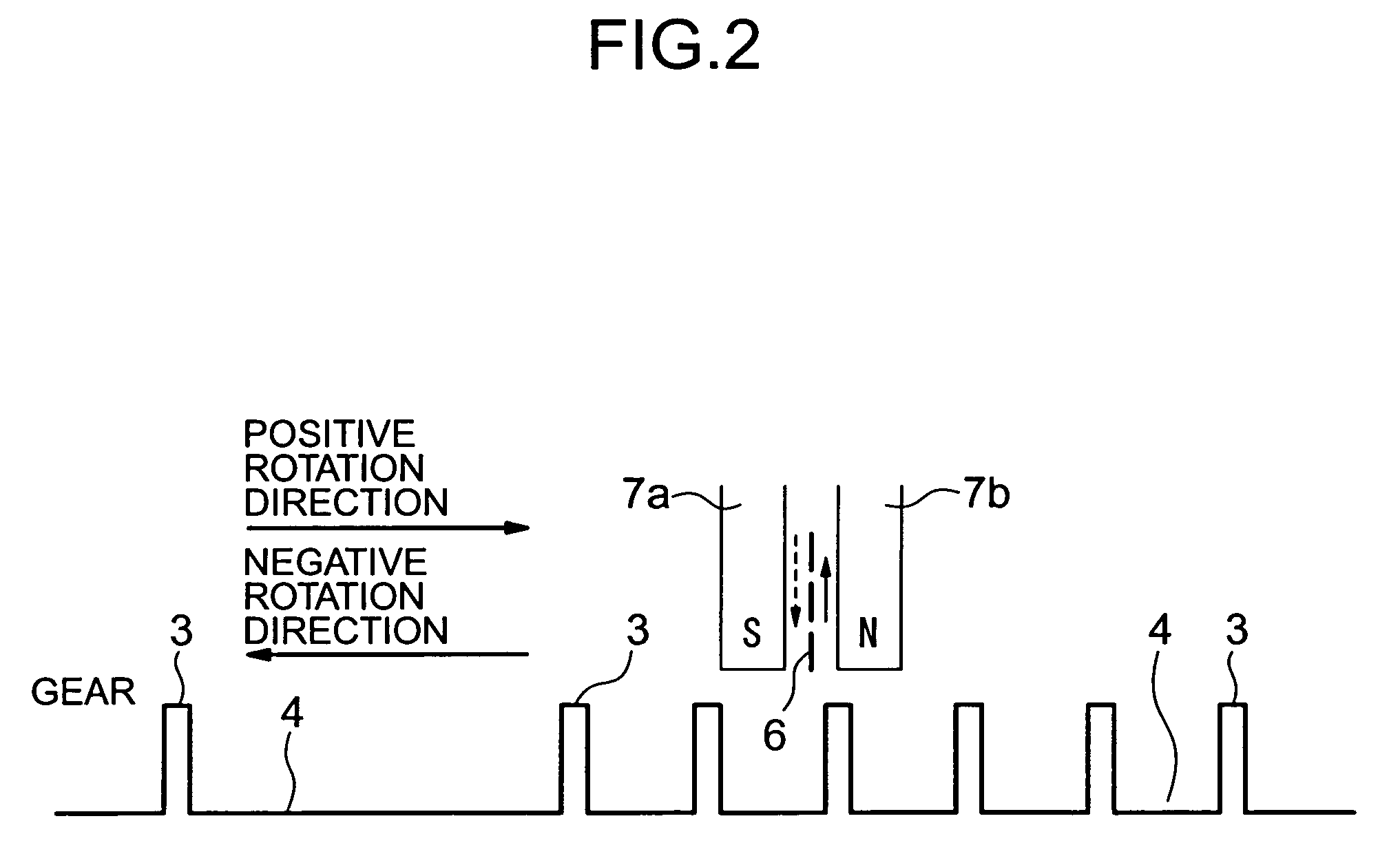

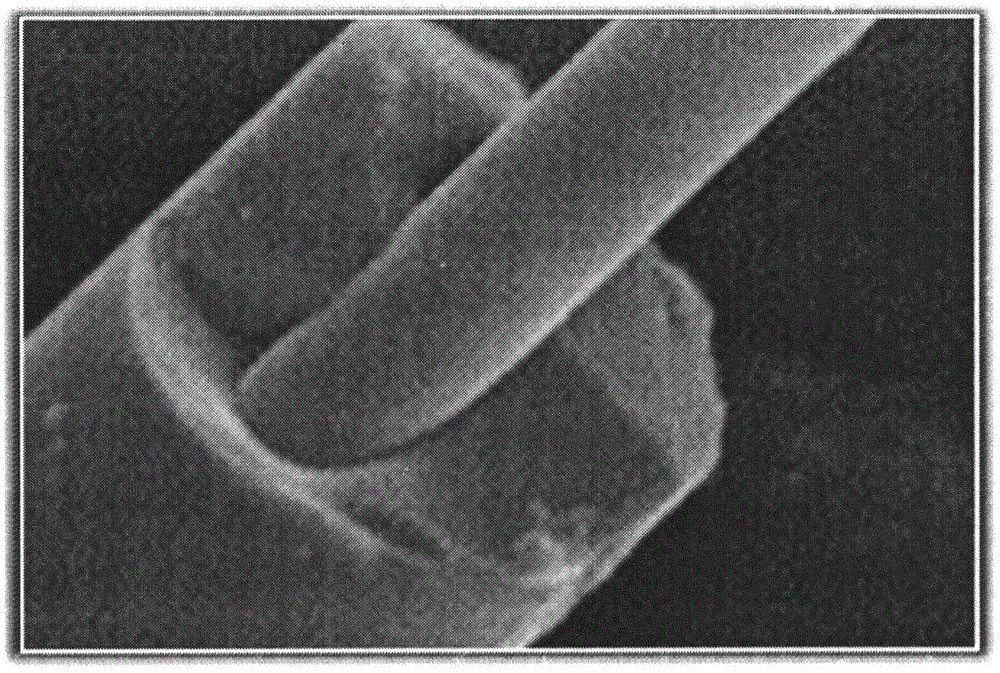

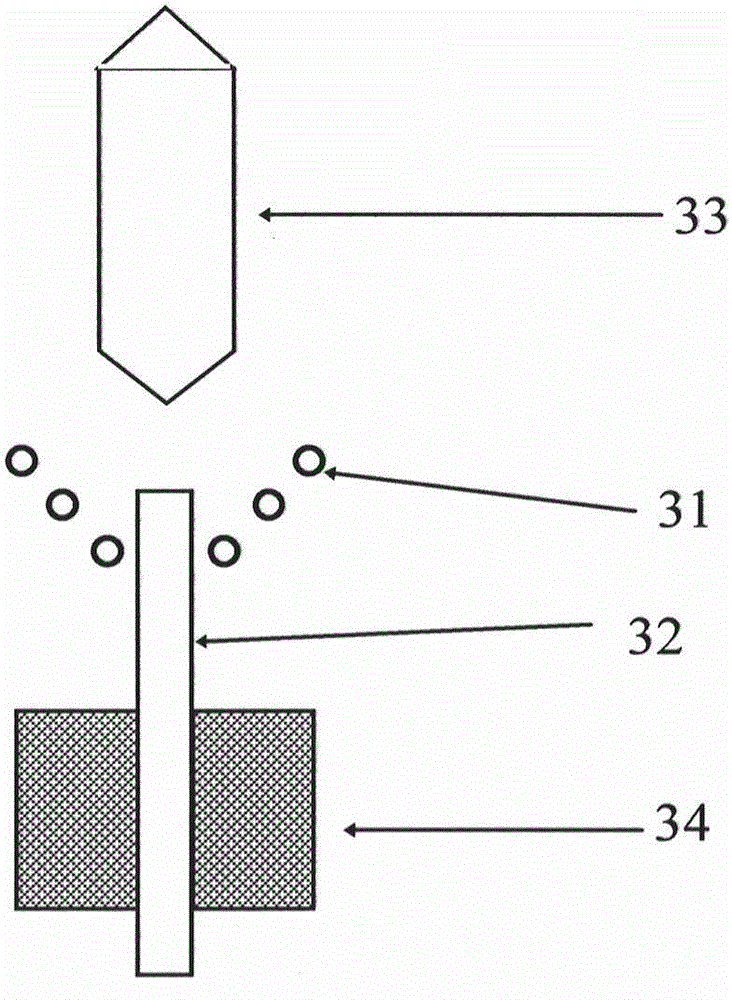

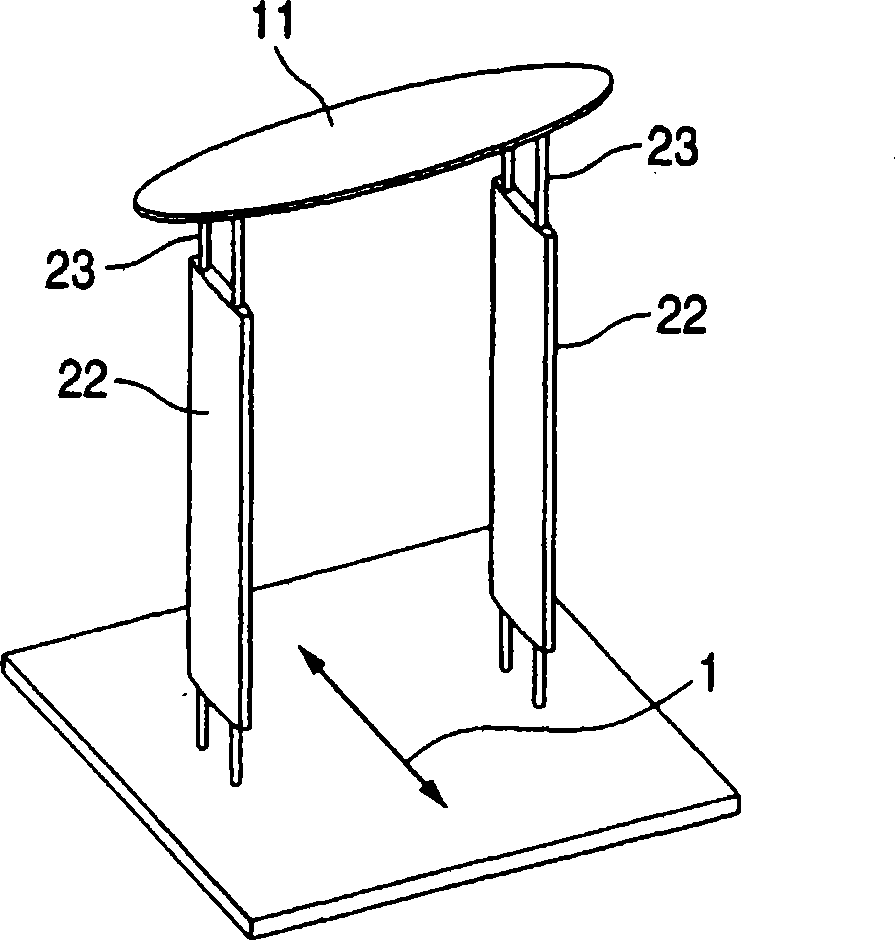

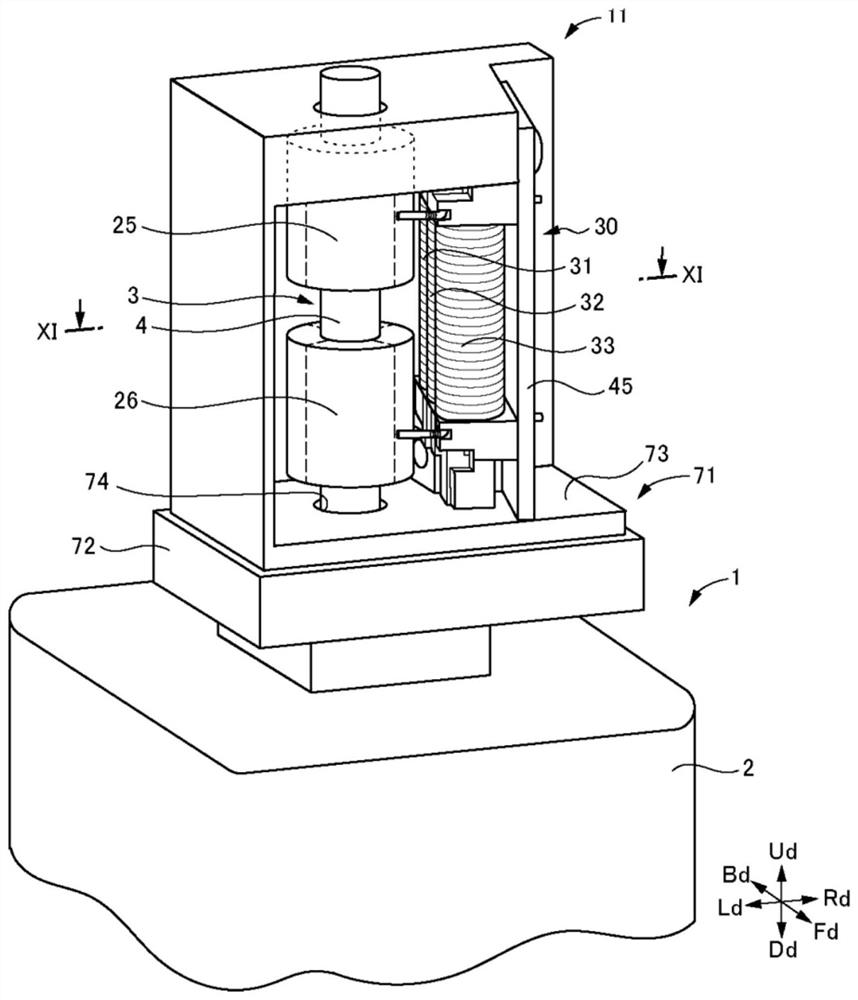

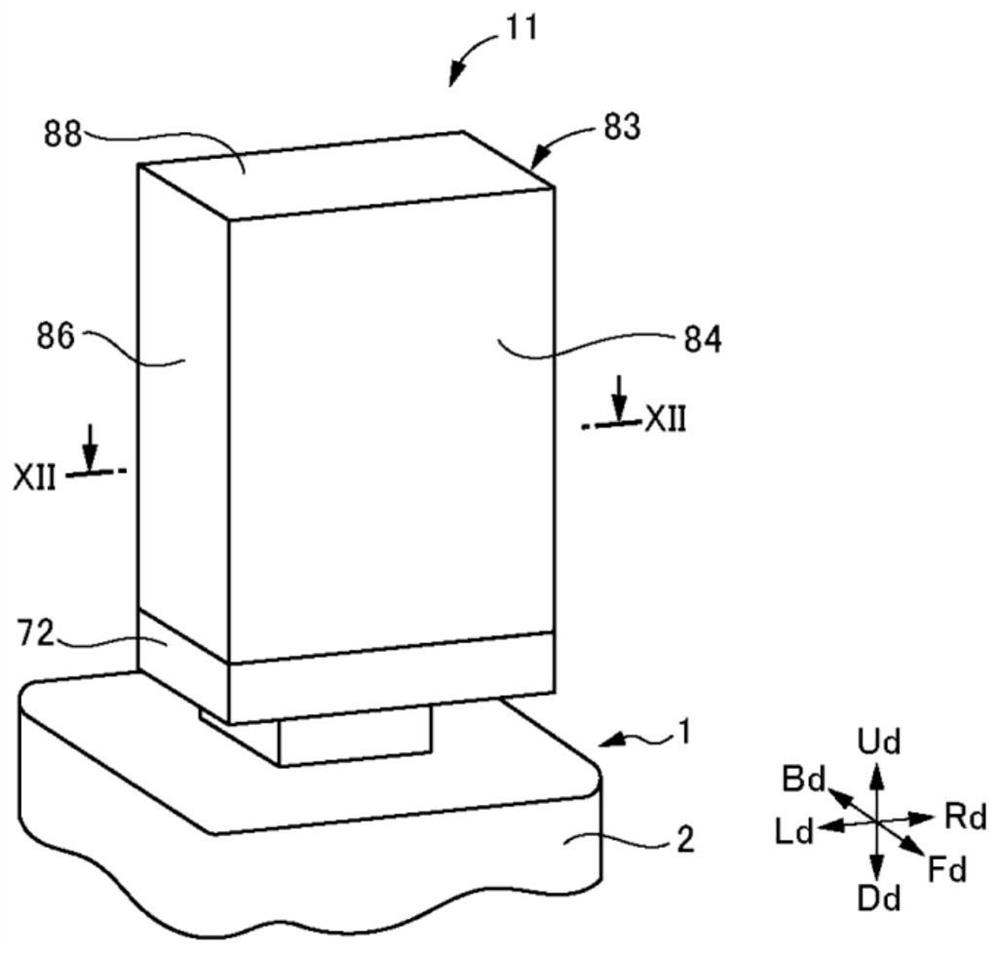

Magnetic detection device and rotation detection device

PendingCN114323087AHigh precisionLinear/angular speed measurementConverting sensor output electrically/magneticallyWire rodRotational axis

The invention relates to a magnetic detection device, which enables the distances between a magnetic wire rod and the axis of a rotating shaft to be equal to each other even if three magnetic sensors are installed on a substrate in a concentrated manner, and improves the precision of signal processing for recognizing the rotation of the rotating shaft. A magnetic detection unit (30) of a rotation detection device is provided with three magnetic sensors (31-33) and a substrate (45) on which the magnetic sensors are mounted. Each magnetic sensor is provided with a magnetic wire (34) that generates a large Barkhausen effect, a coil (35), and a bobbin (36). Each of the magnetic sensors is disposed on the substrate such that the extension direction of the magnetic wire is parallel to the substrate (45), and the magnetic detection unit is disposed on the outer peripheral side of the track of the magnetic field forming unit such that the extension direction of the magnetic wire is parallel to the axial direction of the rotating shaft (3). The positions of the magnetic wire arrangement parts (38) in the bobbins in the magnetic sensors are set so that the distances between the magnetic wires of the three magnetic sensors and the rotating shaft are equal to each other.

Owner:HIROSE ELECTRIC GROUP

Recording paper

ActiveCN101265680BSuppresses temporary degradation of signal strengthShrinkage adjustmentNon-fibrous pulp additionSpecial paperEngineeringFiber orientation

A recording paper contains a pulp fiber and a magnetic fiber having a large Barkhausen effect. The fiber orientation ratio of this recording paper by an ultrasonic propagation velocity method is in a range of more than 1.3 to less than 1.8, and the degree of shrinkage in an MD thereof is 0.25% or less.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com