MnNiSi-based magnetic alloy capable of serving as magnetic refrigeration material

A magnetic refrigeration material and magnetic alloy technology, applied in the field of magnetic alloys, can solve the problems of inoperable magnetic entropy change, narrow working temperature range of materials, and high application cost, and achieve the effects of improving energy conversion efficiency, similar properties, and easy storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

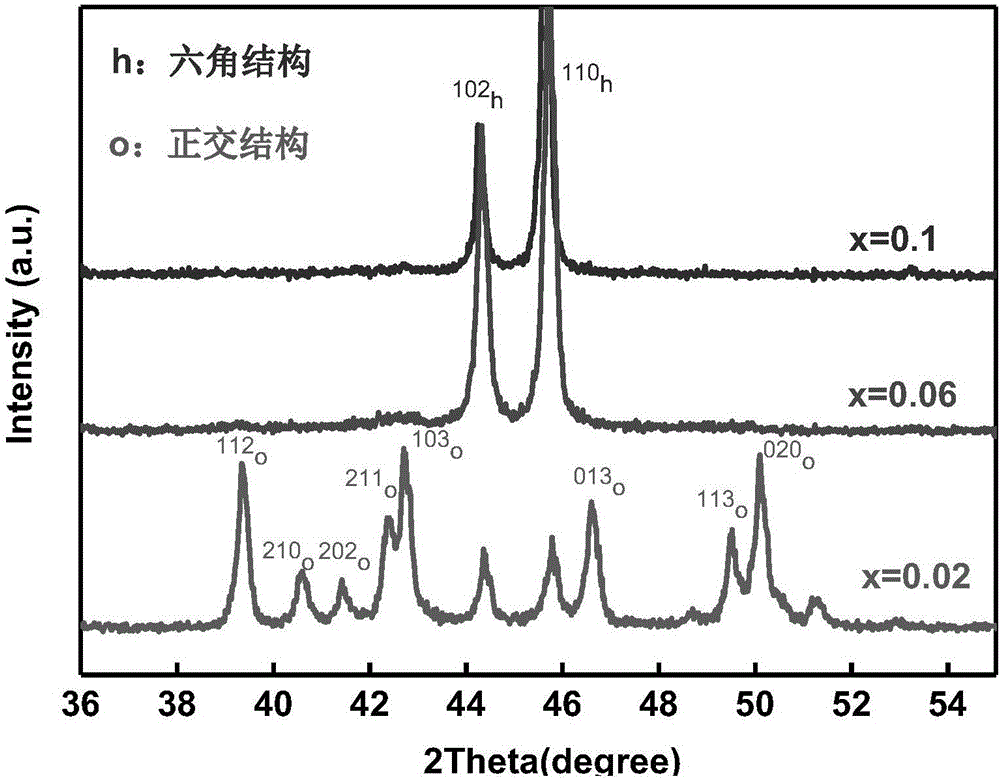

[0039] The chemical formula of this embodiment preparation is Mn 0.4 Fe 0.6 NiSi 1-x Ga x The magnetic alloy bulk, where, Mn 0.4 Fe 0.6 NiSi 1-x Ga x The alloy represents the substitution of 60% (molar ratio) of Mn with Fe and the substitution of (100x)% (molar ratio) of Si with Ga in the MnNiSi alloy. In other embodiments, the same explanation is also made. Its preparation method is carried out according to the following specific steps:

[0040] (4) According to the molar ratio of Mn:Fe:Ni:Si:Ga=0.4:0.6:1:1-x:x, respectively weigh Mn, Fe, Ni, Si, Ga and other raw materials with a purity of 99.9%;

[0041] (5) Put the weighed raw materials into a water-cooled copper crucible, vacuumize with a mechanical pump, and purge with argon, repeat this 4 times, smelt polycrystalline sample ingots by suspension smelting, turn over 3 times for each sample, A total of 4 times of smelting was carried out to ensure uniform composition, and the alloy ingot was prepared.

[0042] (6)...

Embodiment 2

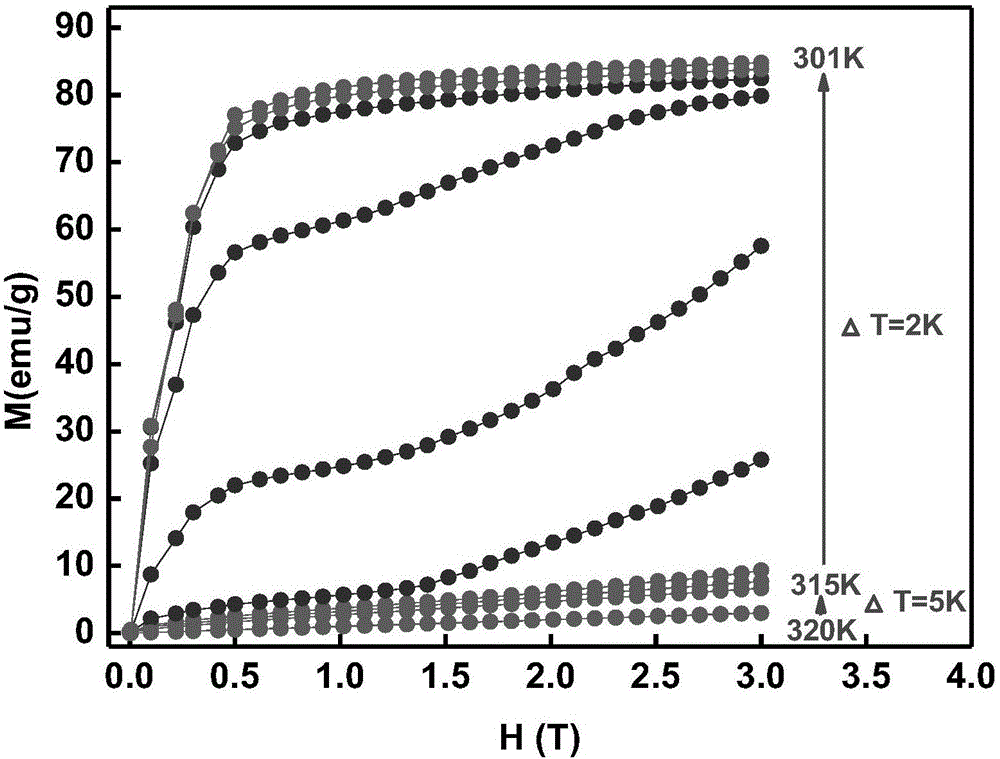

[0045] The chemical formula of this embodiment preparation is Mn 0.8 Fe 0.2 NiSi 1-x Ga x Magnetic phase change alloy: its preparation method is similar to the method of Example 1, except that step (1) reduces the substitution amount of Fe to Mn in the alloy to 20%, and the prepared Mn 0.8 Fe 0.2 NiSi 1-x Ga x The alloy has the same crystal structure and similar variation rules as that of Example (1). and show good magnetic drive performance as image 3 As shown, and the upper limit of the working temperature range is 536K, such as Figure 4 shown.

Embodiment 3

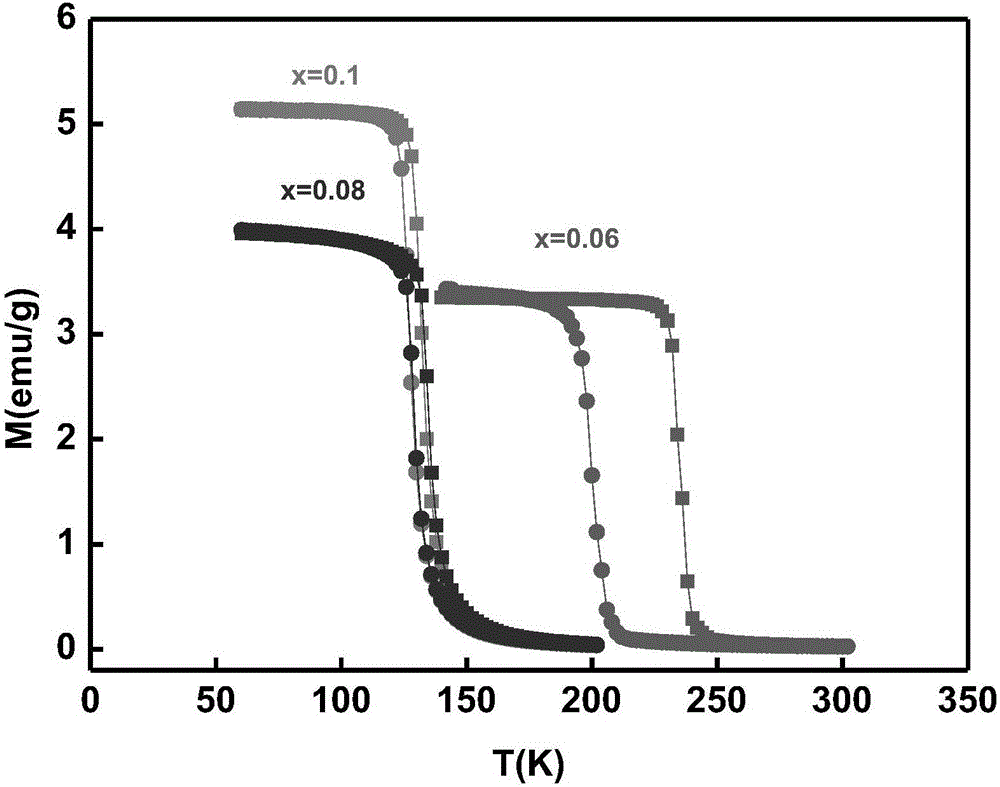

[0047] The chemical formula of this embodiment preparation is Mn 0.6 Fe 0.4 NiSi 1-x Ga x Magnetic phase change alloy: its preparation method is similar to the method of Example 1, the difference is that step (1) reduces the substitution amount of Fe to Mn in the alloy to 40%, and the prepared Mn 0.6 Fe 0.4 NiSi 1-x Ga x The alloy obtains a wide working temperature range up to 330K near room temperature and considerable magnetic entropy change. mn 0.4 Fe 0.6 NiSi 1-x Ga x The corresponding magnetization temperature dependence curve of the alloy is as follows Figure 5 As shown, Mn 0.6 Fe 0.4 NiSi 0.88 Ga 0.12 The magnetic entropy change-temperature curve of the alloy is as follows Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com