Material capable of regulating and controlling magnetism and related magnetic effects through bending or twisting, preparation method of material and application of material

A technology related to magnetism and magnetism, which is applied in the direction of magnetic materials, magnetic objects, and the magnetism of inorganic materials, can solve the problems of complex pressure application methods, poor controllability, and application limitations, and achieve good magnetocaloric effect, strong torsion controllability, The effect of simple pressure application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

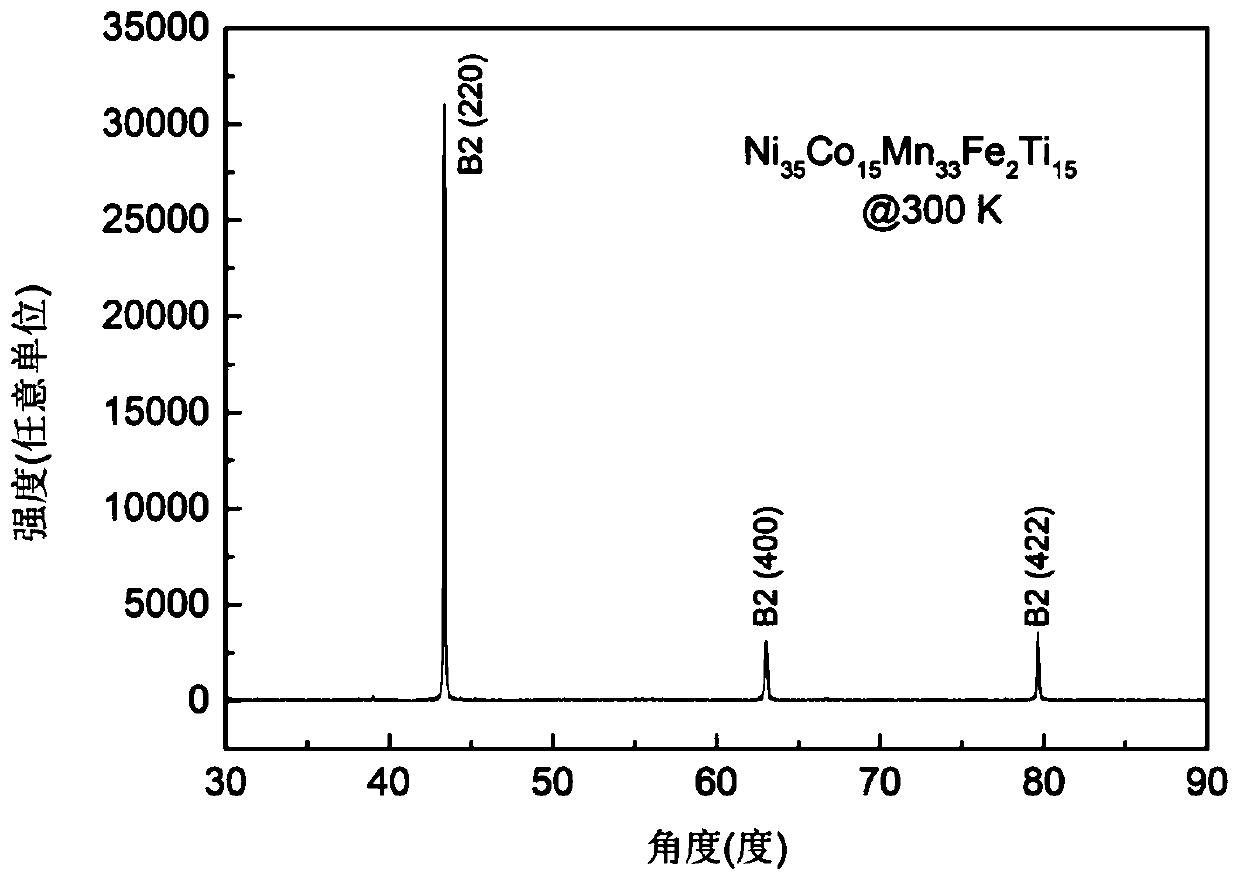

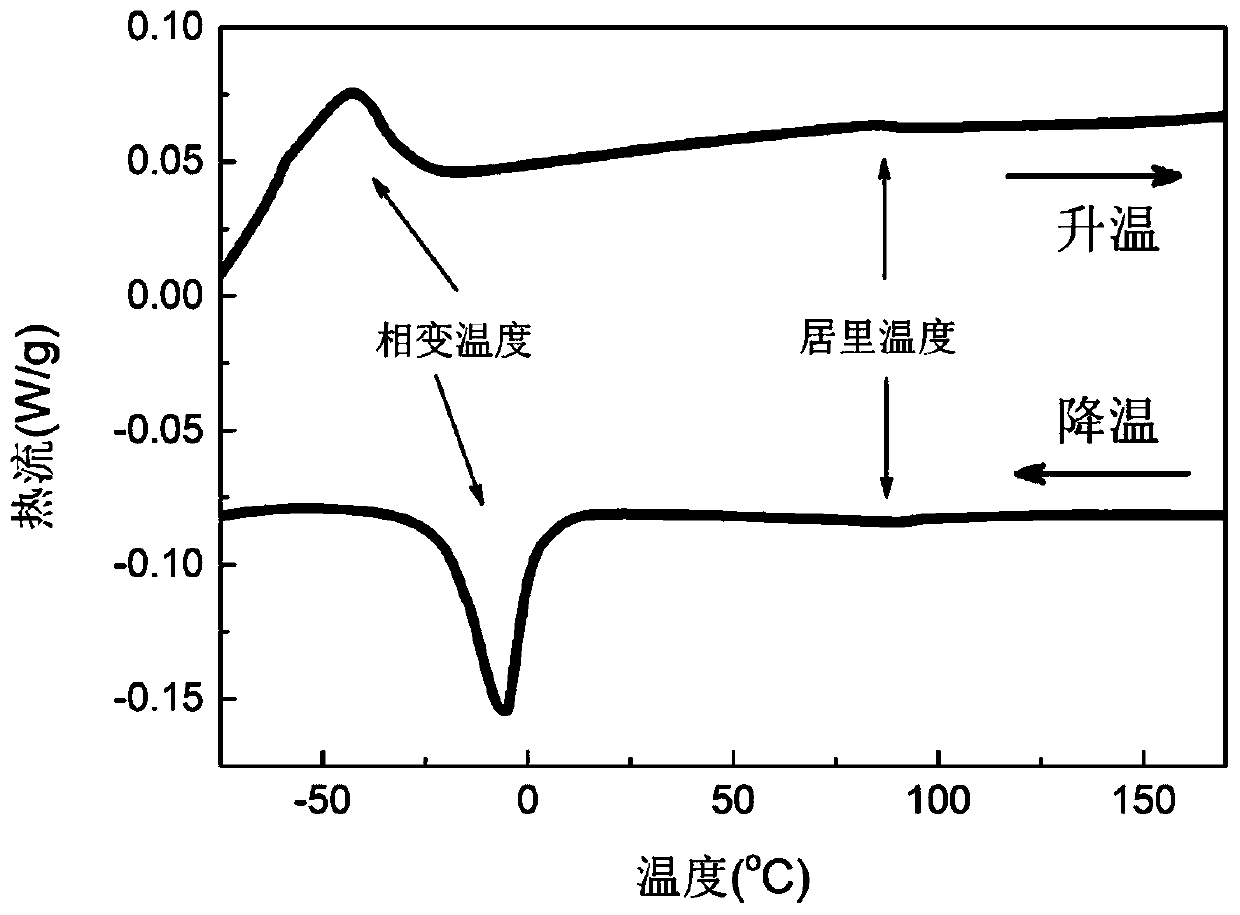

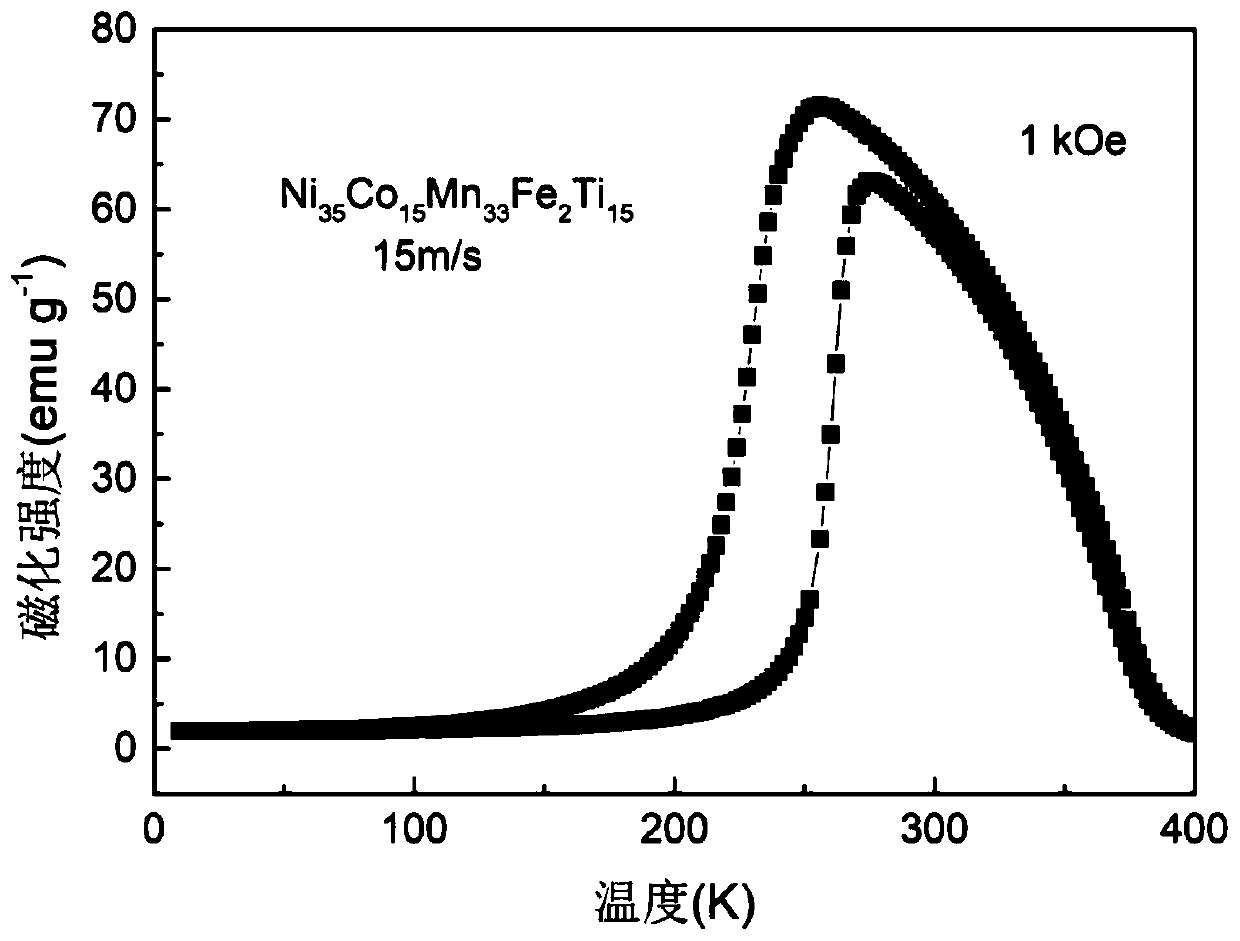

[0046] A material whose magnetism and related magnetic effects can be tuned by bending or twisting, its chemical formula is Ni 35 co 15 mn 33 Fe 2 Ti 15 , the material preparation method comprises the following steps:

[0047] (1) Ingredients: Weigh high-purity raw materials Ni, Mn, Fe, Co, Ti according to the ratio in the chemical formula, and carefully polish off the oxide layer on the surface of the required transition metal elements before ingredients.

[0048] Taking Mn as an example, it needs to be cleaned and smelted to ensure the purity of the raw material. The specific steps are as follows: 1) Put a certain amount of Mn element in the beaker, and then pour it into the beaker diluted with water at a volume ratio of about 1:1. Dilute hydrochloric acid solution to cause a chemical reaction, and stir it quickly with a glass rod during the reaction; 2) Wait until the oxide disappears and the surface of Mn shows a bright metallic luster, then quickly pour out the waste ...

Embodiment 2

[0055] A material whose magnetism and related magnetic effects can be tuned by bending or twisting, its chemical formula is Ni 38 co 12 mn 35 sn 5 , the material preparation method comprises the following steps:

[0056] (1) Ingredients: Weigh high-purity raw materials Ni, Mn, Co and Sn according to the ratio in the chemical formula, and carefully polish off the oxide layer on the surface of the required transition metal elements before ingredients.

[0057] (2) Melting: Melting is carried out in a water-cooled copper crucible electric arc furnace, and the electric arc furnace is cooled by a circulating water cooling system. The prepared raw materials are carefully placed at the bottom center of the copper crucible, and the positions of different samples are recorded, and then Lower the stove lid. Before starting smelting, the furnace must be evacuated. The vacuuming process is divided into two stages: first use a mechanical pump to pump to about 5 Pa, and then use a diff...

Embodiment 3

[0062] A material whose magnetism and related magnetic effects can be tuned by bending or twisting, its chemical formula is Ni 34 co a mn 30 Fe 5 Ge 10 , the material preparation method comprises the following steps:

[0063] (1) Ingredients: Weigh high-purity raw materials Ni, Mn, Fe, Co and Ge according to the ratio in the chemical formula. Before ingredients, carefully polish off the oxide layer on the surface of the transition metal elements.

[0064] (2) Melting: Melting is carried out in a water-cooled copper crucible electric arc furnace, and the electric arc furnace is cooled by a circulating water cooling system. The prepared raw materials are carefully placed at the bottom center of the copper crucible, and the positions of different samples are recorded, and then Before lowering the furnace lid to start smelting, the furnace must be evacuated. The vacuuming process is divided into two stages: first use a mechanical pump to pump to about 5 Pa, and then use a dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com