Method for improving room-temperature ductility of LPSO structural phase-containing Mg-RE-Zn system alloy

An alloy and room temperature technology, which is applied in the field of heat treatment and phase transformation of metal materials, can solve problems such as limited effects, and achieve the effects of simple method, increased elongation, and improved plasticity of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0033] The specific implementation of the present invention includes the following steps:

[0034] 1. Alloy melting

[0035] The ingredients are calculated according to the mold size of Φ100×400mm. The raw materials are pure Mg block, pure rare earth Gd, Y and Nd, pure Zn block and Mg-30wt.% Zr intermediate alloy. The designed ingot weight before smelting is 5kg, and the results of smelting and composition testing can be calculated: Mg yield is 98.8%, pure RE yield is 90%, Zn yield is 100%, Mg-30wt. The yield of %Zr master alloy is 25%.

[0036] 1.1 Preparation before smelting

[0037] (1) Weigh, prepare the charge, first remove the corrosives and oxides on the charge, remove the rust from the tools, and preheat all molds, raw materials, fluxes, etc. to 150°C;

[0038] (2) Connect the protective gas pipeline, the protective gas is Ar 2 Gas is used to smelt magnesium alloys with steel crucibles, which are always protected during the smelting process. Temperature control is an important...

Embodiment 2

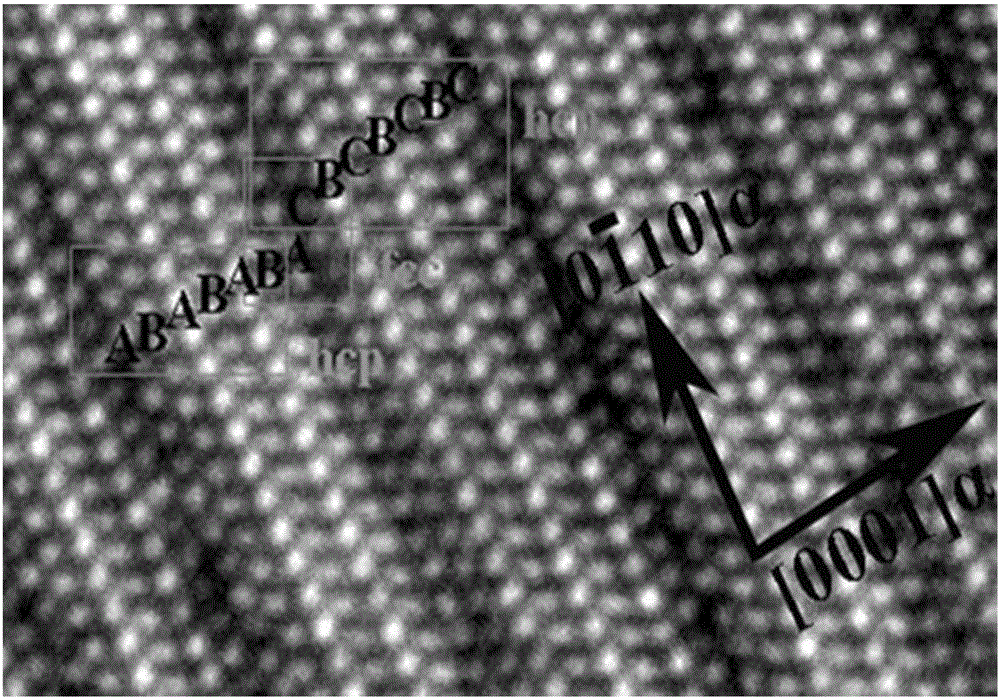

[0057] The method for improving the room temperature plasticity of the alloy based on the morphology control of the LPSO structural phase proposed in the present invention is to obtain a massive LPSO structural phase after the as-cast Mg-RE-Zn series alloy undergoes two-stage homogenization heat treatment. After the alloy is cooled to a certain temperature with the furnace for short-term heat preservation, and the Mg-RE phase particles and precipitation phases cannot appear in the microstructure during the furnace cooling process, the massive LPSO structure phase is transformed into the needle-like LPSO structure phase. Subsequently, subsequent hot extrusion and aging heat treatment are performed, and finally a highly plastic Mg-RE-Zn alloy containing needle-like LPSO structure phase is obtained.

[0058] This method is suitable for all Mg-RE-Zn series alloys containing LPSO structure phase, but the specific process parameters are adjusted accordingly according to the alloy compos...

Embodiment 3

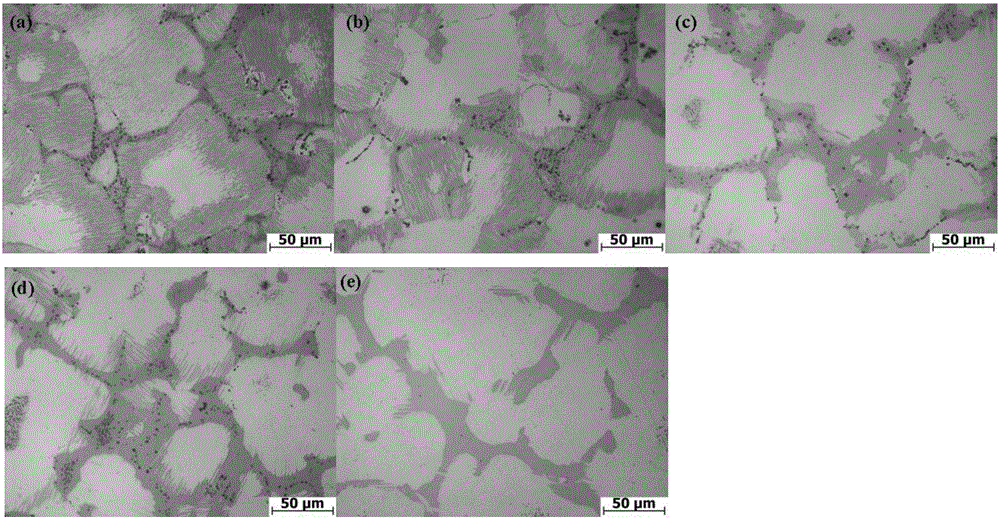

[0065] The as-cast Mg-7Gd-3Y-1Nd-1Zn-0.5Zr (wt.%) in Example 1 was cooled to 440℃, 450℃, 460℃, 470℃, 480℃ after two-stage homogenization heat treatment. , 490°C, 500°C temperature nodes and heat preservation at the above different temperatures for 2h, and the remaining steps are consistent with those disclosed in Example 1. The mechanical properties of the finally obtained material were tested, and the results are shown in Table 3.

[0066] table 3

[0067] temperature440℃450℃460℃470℃480℃490℃500℃ Sample plasticity A / %7.38.211.5111287

[0068] From the comparison of the data in Table 3, it can be seen that the cooling time is the same with the furnace, but at the four temperature nodes of 440℃, 450℃, 490℃, and 500℃, the plasticity changes little, but it is obviously better than 460℃, 470℃, 480℃. The three temperatures are low, so the above data comparison shows that only in the furnace cooling temperature range of the present invention can the room temperature plasticity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com