Preparation method of NCM ternary positive electrode material doped with Y<3+> on surface

A cathode material and surface layer technology, which is applied in the field of preparation of NCM ternary cathode materials, can solve problems such as unstable rate performance, and achieve the effects of improving structural stability and reversible discharge capacity, easy process and technology, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

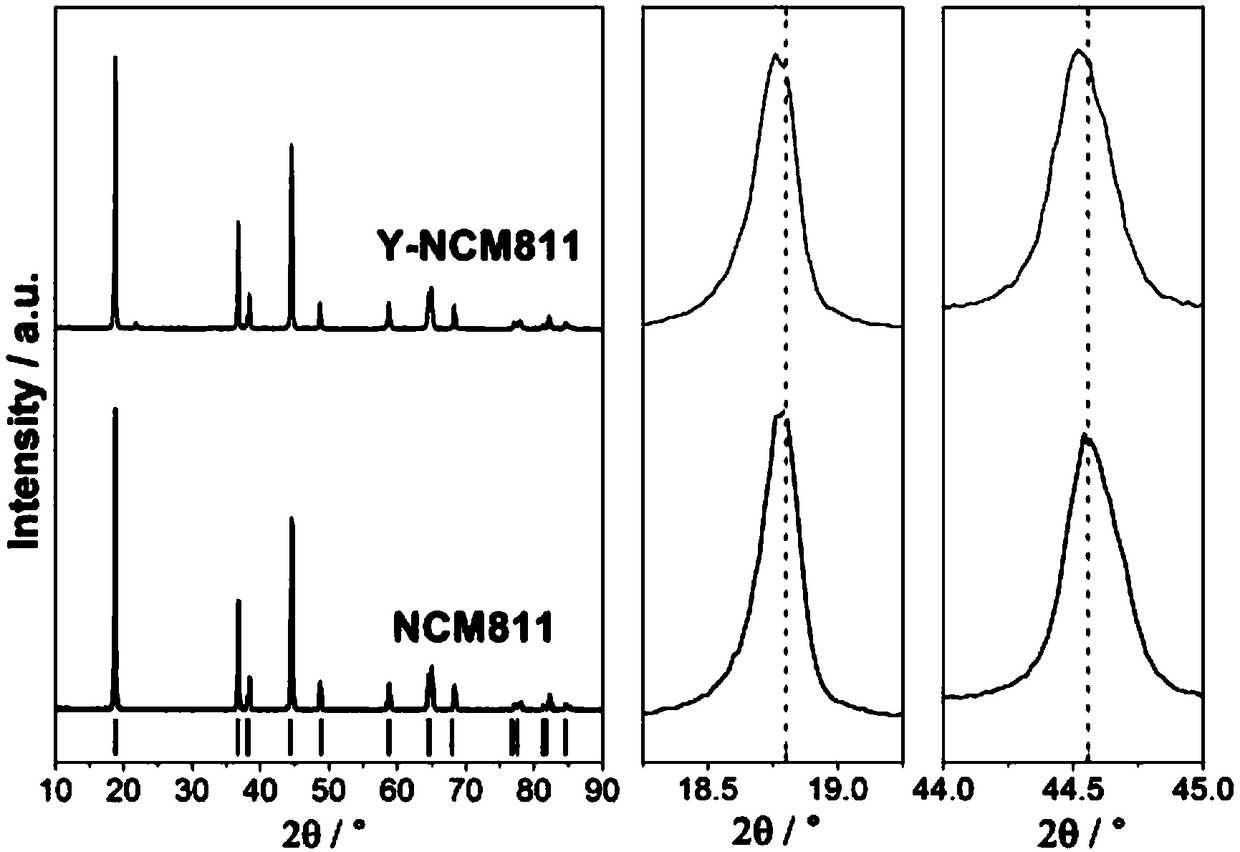

[0035] LiOH·H 2 O was added to the mortar, and after dry grinding for 15 min, it was mixed with Ni 0.8 co 0.1 mn 0.1 (OH) 2 and Y(NO 3 ) 3 ·6H 2 O was ultrasonicated in ethanol for 1.5h, and then the ultrasonicated mixture was transferred to a mortar, dry-milled for 25min, then added with ethanol and continued to be milled for 25min, then the wet-milled mixture was placed in an oxygen atmosphere, and heated to 450 ℃ and keep it for 6 hours, then raise the temperature to 750 ℃ and keep it for 12 hours, then cool with the furnace to get the surface doped Y 3+ The NCM ternary cathode material Li[Ni 0.79 co 0.1 mn 0.1 Y 0.01 ]O 2 , abbreviated as Y-NCM811; among them, LiOH·H 2 O and Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio of Y(NO 3 ) 3 ·6H 2 O and Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio of nickel ions in the medium is 1:79.

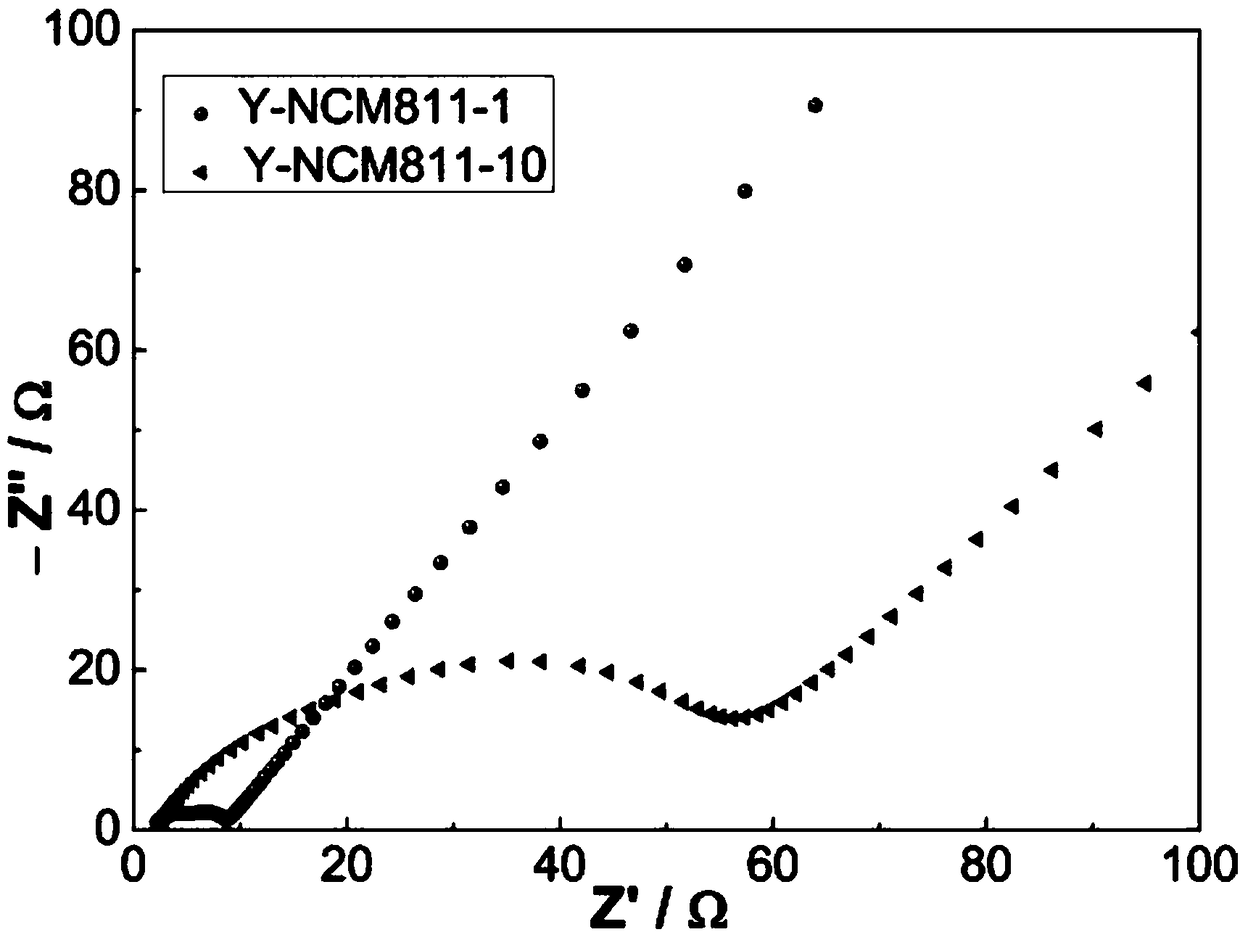

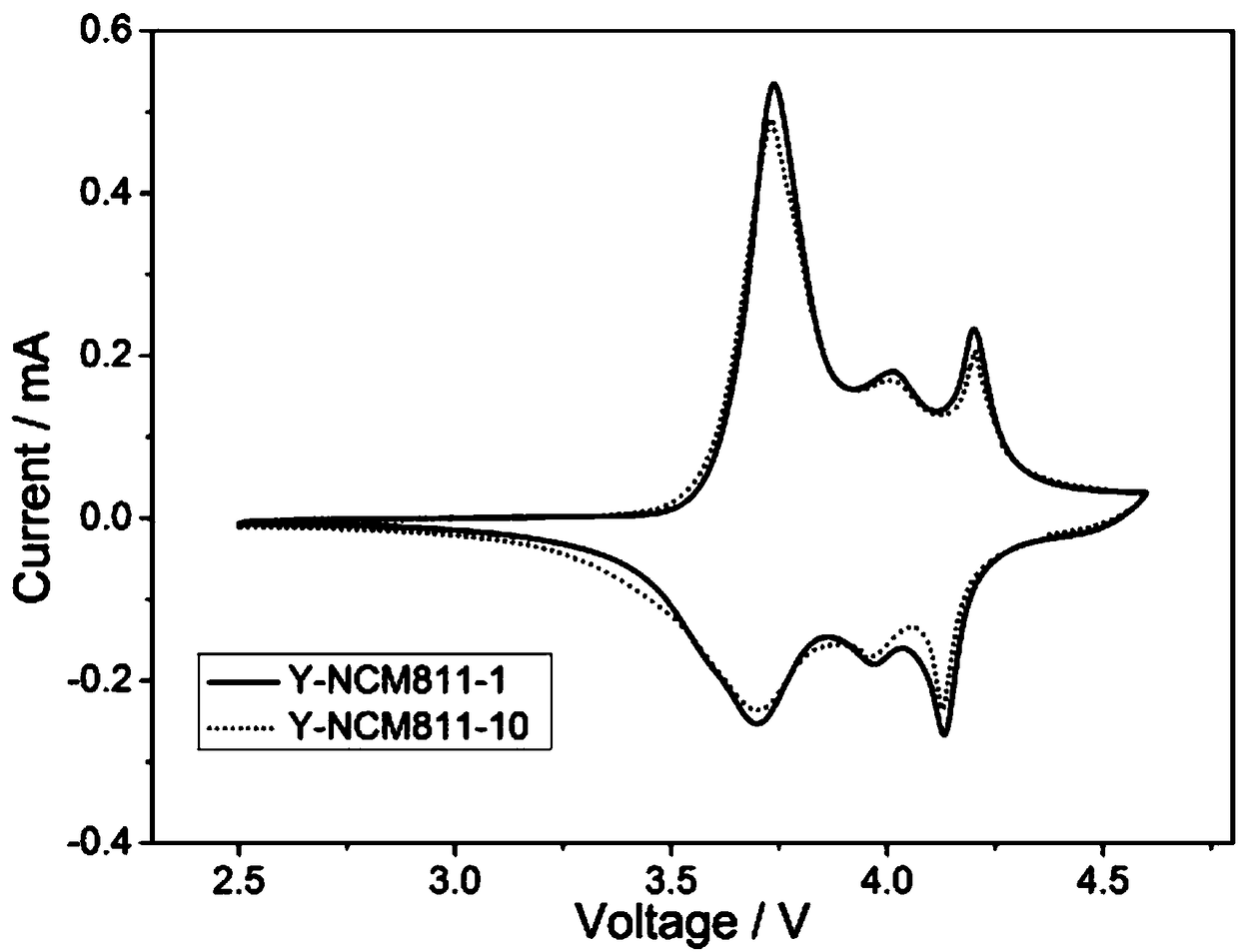

[0036] The Y-NCM811 prepared in Example 1 was used as the positive electrode material to assemble a CR2025 button battery, ...

Embodiment 2

[0047] LiOH·H 2 O was added to the mortar, and after dry grinding for 15 min, it was mixed with Ni 0.8 co 0.1 mn 0.1 (OH) 2 and Y(NO 3 ) 3 ·6H 2 O was sonicated in ethanol for 2 hours, and then the sonicated mixture was transferred to a mortar, dry-milled for 25 minutes, then added with ethanol and continued to grind for 25 minutes, then the wet-milled mixture was placed in an oxygen atmosphere, and heated to 450 °C And keep it warm for 6 hours, then raise the temperature to 750°C and keep it warm for 12 hours, and cool down with the furnace to get the surface doped Y 3+ The NCM ternary cathode material Li[Ni 0.795 co 0.1 mn 0.1 Y 0.005 ]O 2 , abbreviated as Y-NCM811; among them, LiOH·H 2 O and Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio of Y(NO 3 ) 3 with you 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio of nickel ions in the medium is 1:159.

[0048] Y-NCM811 prepared by embodiment 2 is assembled into CR2025 button cell as positive electrode material and ca...

Embodiment 3

[0050] LiOH·H 2 O was added to the mortar, and after dry grinding for 15 min, it was mixed with Ni 0.8 co 0.1 mn 0.1 (OH) 2 and Y(NO 3 ) 3 ·6H 2 O was sonicated in ethanol for 2 hours, then the sonicated mixture was transferred to a mortar, dry-milled for 25 minutes, then added with ethanol and continued to grind for 25 minutes, then the wet-milled mixture was placed in an oxygen atmosphere, and heated to 450°C And keep it warm for 6 hours, then raise the temperature to 750°C and keep it warm for 12 hours, and cool down with the furnace to get the surface doped Y 3+ The NCM ternary cathode material Li[Ni 0.785 co 0.1 mn 0.1 Y 0.015 ]O 2 , abbreviated as Y-NCM811; among them, LiOH·H 2 O and Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio of Y(NO 3 ) 3 ·6H 2 O and Ni 0.8 co 0.1 mn 0.1 (OH) 2 The molar ratio of nickel ions in the medium is 1:52.3.

[0051] Y-NCM811 prepared by embodiment 3 is assembled into CR2025 button cell as positive electrode material and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com