Adhesion La (Fe, Si)<13> bulk-shaped magnet with excellent heat-conducting property and preparation method therefor

A technology with thermal conductivity and lafe11.5si1.5, applied in magnetic objects, magnetic materials, metal processing equipment, etc., can solve problems such as reducing magnetic refrigeration efficiency and refrigerator life, blocking circulating air paths, and poor corrosion resistance. Achieve good magnetocaloric effect, excellent thermal conductivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

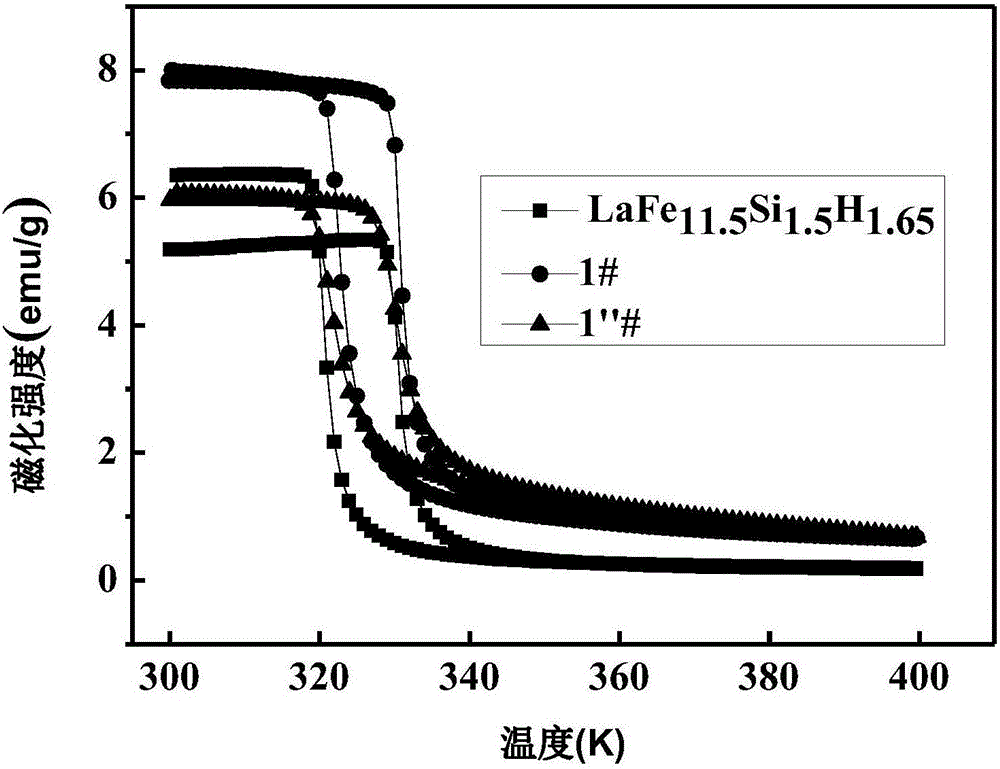

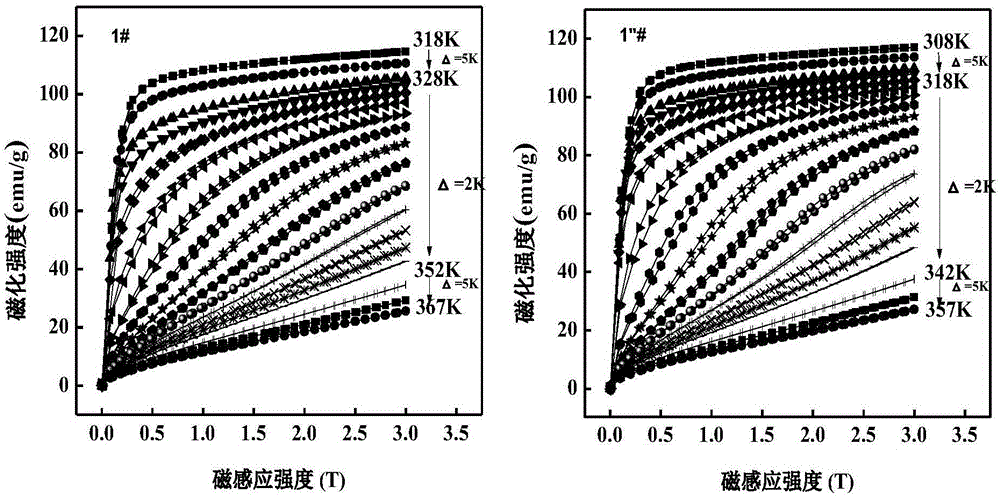

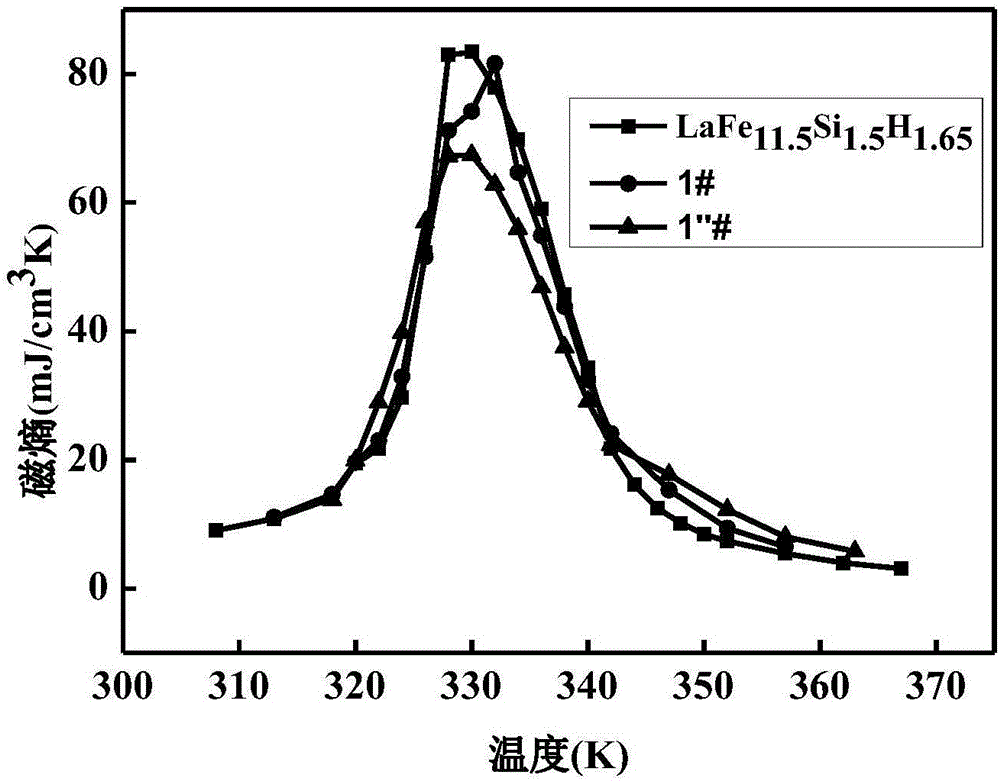

[0042] Example 1: A bonded La(Fe,Si) with excellent thermal conductivity 13 The preparation method of the block magnet is carried out according to the following steps.

[0043] Step one, press LaFe 11.5 Si 1.5 Chemical formula ingredients;

[0044] In the second step, the raw materials prepared in the first step are put into the suspension melting furnace, vacuumized, and repeatedly smelted four times under the protection of argon to obtain alloy ingots;

[0045] In the third step, the alloy ingot smelted in the second step is sealed in a high-vacuum quartz tube, annealed at 1120 ° C for 21 days, the quartz tube is broken and quenched in ice water to prepare a NaZn 13 Structure LaFe 11.5 Si 1.5 Magnetocaloric effect alloy;

[0046]The fourth step is to cut the magnetocaloric alloy in the third step into irregular small particles, put them into an autoclave, and perform hydrogenation treatment at a hydrogen pressure of 5MPa and a temperature of 50°C to obtain LaFe 11.5 S...

Embodiment 2

[0061] Example 2: A bonded La(Fe,Si) with excellent thermal conductivity 13 The preparation method of the block magnet is carried out according to the following steps.

[0062] Step one, press LaFe 11.5 Si 1.5 Chemical formula ingredients;

[0063] In the second step, the raw materials prepared in the first step are put into the suspension melting furnace, vacuumized, and repeatedly smelted four times under the protection of argon to obtain alloy ingots;

[0064] In the third step, the alloy ingot smelted in the second step is sealed in a high-vacuum quartz tube, annealed at 1120 ° C for 21 days, the quartz tube is broken and quenched in ice water to prepare a NaZn 13 Structure LaFe 11.5 Si 1.5 Magnetocaloric effect alloy;

[0065] The fourth step is to cut the magnetocaloric alloy in the third step into irregular small particles, put them into an autoclave, and perform hydrogenation treatment at a hydrogen pressure of 5MPa and a temperature of 50°C to obtain LaFe 11.5 ...

Embodiment 3

[0081] Example 3: A bonded La(Fe,Si) with excellent thermal conductivity 13 The preparation method of the block magnet is carried out according to the following steps.

[0082] Step one, press LaFe 11.5 Si 1.5 Chemical formula ingredients;

[0083] In the second step, the raw materials prepared in the first step are put into the suspension melting furnace, vacuumized, and repeatedly smelted four times under the protection of argon to obtain alloy ingots;

[0084] In the third step, the alloy ingot smelted in the second step is sealed in a high-vacuum quartz tube, annealed at 1120 ° C for 21 days, the quartz tube is broken and quenched in ice water to prepare a NaZn 13 Structure LaFe 11.5 Si 1.5 Magnetocaloric effect alloy;

[0085] The fourth step is to cut the magnetocaloric alloy in the third step into irregular small particles, put them into an autoclave, and perform hydrogenation treatment at a hydrogen pressure of 5MPa and a temperature of 50°C to obtain LaFe 11.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com