Rare earth-based bulk metallic glass with adjustable rear earth ingredient content

A bulk metal, rare earth-based technology, applied in the field of rare earth-based bulk metallic glass, can solve the problems of increasing the difficulty of preparing rare-earth-based bulk metallic glass and the difficulty of maintaining a specific ratio of rare earth elements, so as to reduce the difficulty of preparation and reduce the cost of preparation , excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

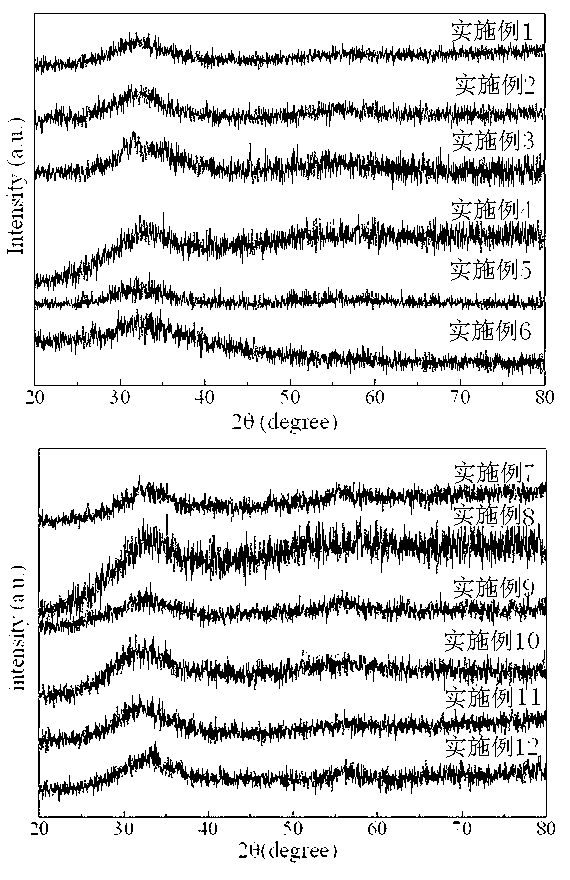

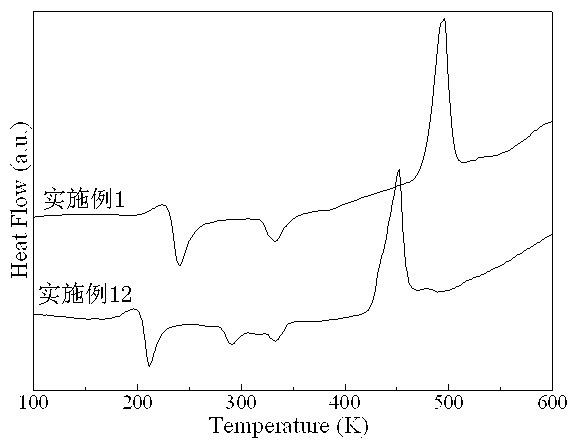

Embodiment 1-12

[0027] Table 1

[0028]

[0029] Take the metal raw material according to the atomic percentage in the different embodiments of Table 1: cerium , lanthanum , praseodymium , samarium , gadolinium , cobalt and aluminum (purity ≥ 99.5%), a total of 50g. Put the metal raw material in a copper mold cooled by circulating water, pass in 0.6MPa argon gas under vacuum conditions, and adjust the distance between the tungsten electrode and the metal raw material to be 1cm under the voltage of 380V; turn on the power, start the arc ; Repeated melting 3 times to ensure that the alloy components are evenly mixed to obtain an alloy master ingot. The obtained alloy master ingot is put into an electric arc furnace for re-melting, and at the same time, the suction casting valve is opened, and the pressure difference is controlled at 0.4 MPa for suction casting to obtain a rare earth-based bulk metallic glass with adjustable rare earth component content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com