Gadolinium borate and preparation method and application thereof

A technology of gadolinium borate and boric acid, applied in the field of gadolinium borate, can solve problems such as low efficiency and destroy the ozone layer, and achieve the effects of broad application prospects, high magnetocaloric effect, and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation process of gadolinium borate magnetic refrigeration material: 0.5mmol gadolinium oxide and 1mmol boric acid were placed in a quartz porcelain boat. The solid was ground into a powder using an agate mortar, mixed well and dried overnight. Transfer the porcelain boat to a 120cm×Φ50 quartz tube furnace, raise the temperature to 400°C at a rate of 300°C / h and keep the temperature constant for 600 minutes, then raise the temperature to 1000°C at a rate of 200°C / h and hold the temperature for 6 hours, and then increase the temperature at 50°C / h The temperature was cooled to room temperature at a rate of h to obtain a white powder solid. The product was washed with absolute ethanol and deionized water, filtered with suction, and dried overnight to obtain white powdery crystals.

Embodiment 2

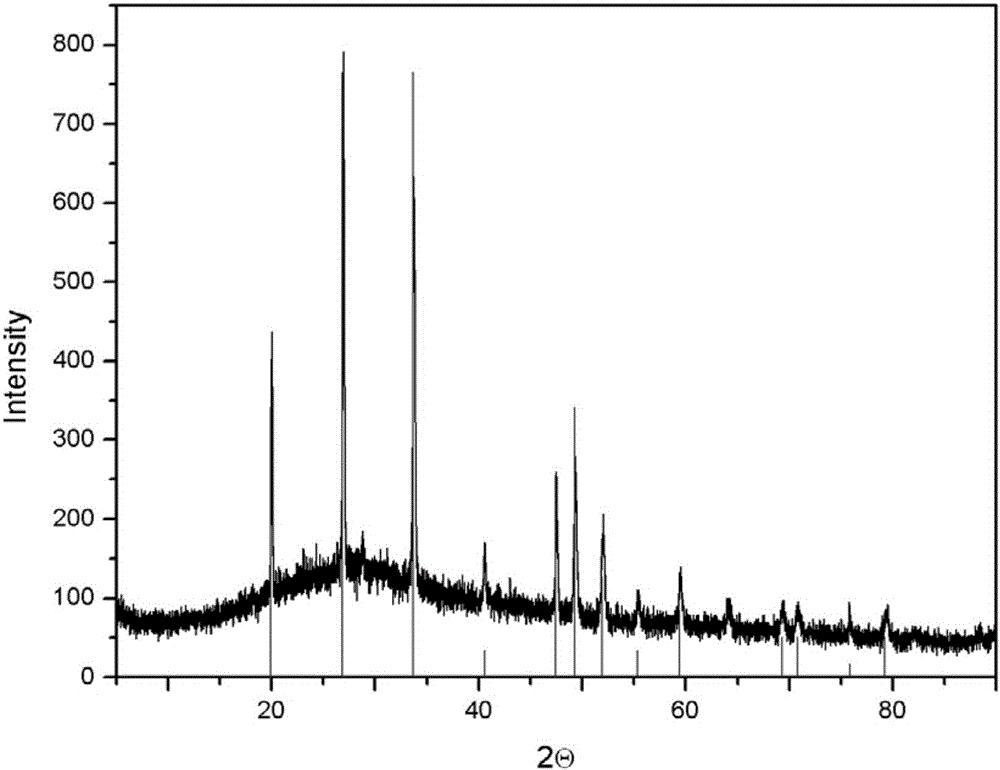

[0027] Structure Characterization

[0028] The powder sample crystal structure of gadolinium borate magnetic refrigeration material was collected by Rigaku Ultima IV X-ray single crystal diffractometer at 298K. figure 1 It is the XRD pattern of the gadolinium borate magnetic refrigeration material. from figure 1 It can be seen that the experimental diffraction peaks of its XRD are basically consistent with the XRD data (straight line) fitted according to the single crystal structure. The peak shape of each characteristic diffraction peak is good, and the baseline is relatively stable, indicating that the sample has no impurity phase, high purity, and good crystal phase.

[0029] Gadolinium borate magnetic refrigeration material: it belongs to the hexagonal crystal system, the space group is 6mm, and the molecular formula is GdBO 3 , the unit cell parameters are a=3.829, b=3.829, c=8.89, V=112.9.

Embodiment 3

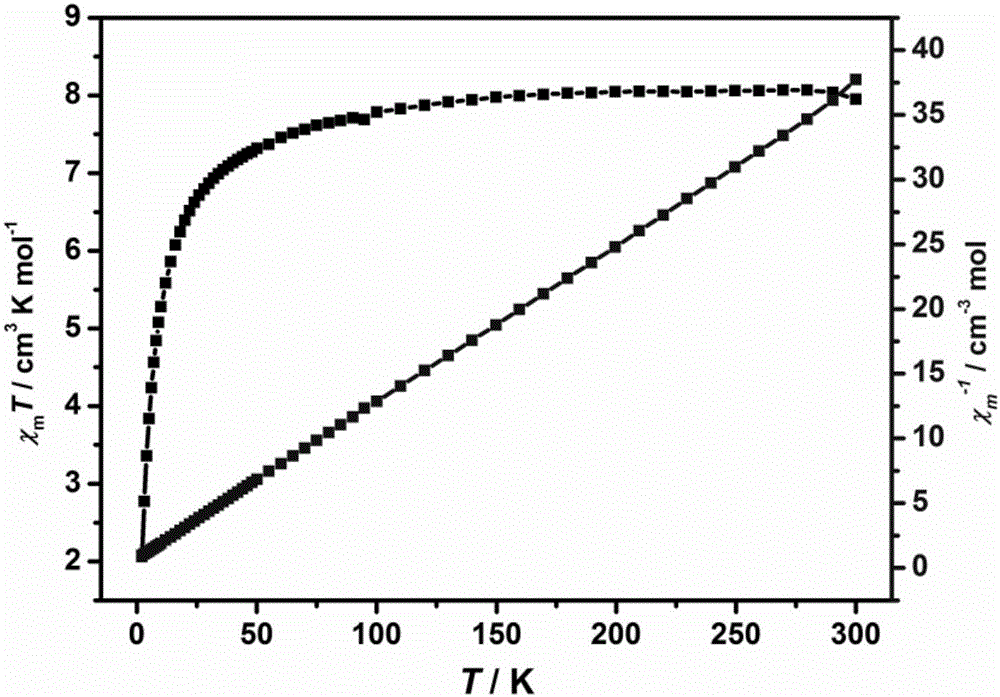

[0031] magnetic test

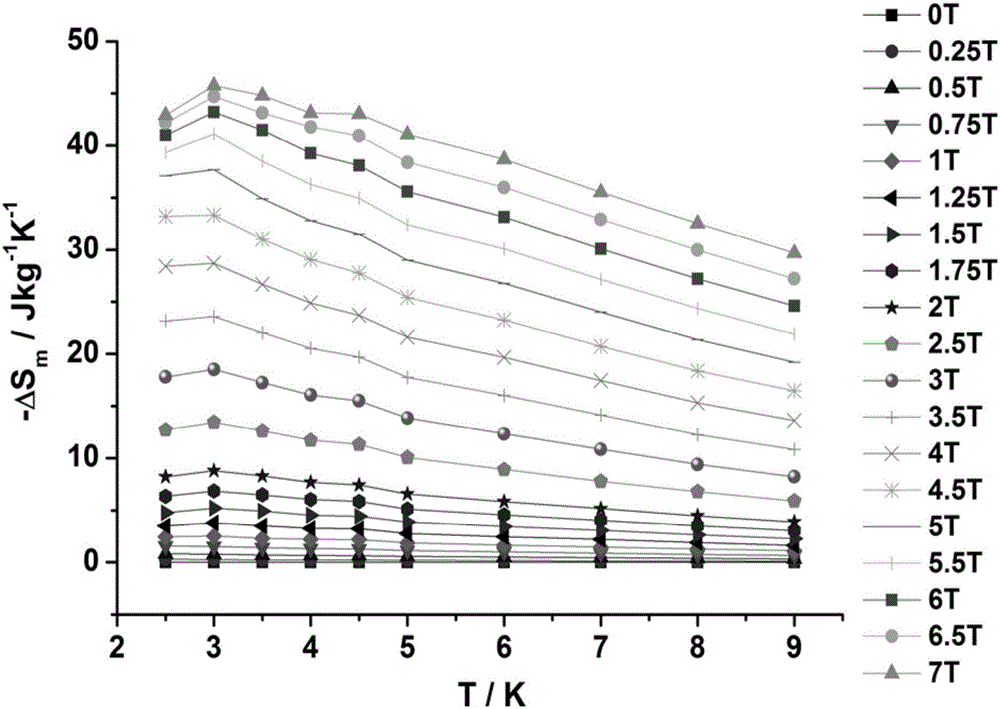

[0032] A Quantum Design SQUID MPMS magnetometer was used to test the gadolinium borate magnetic refrigeration material under the conditions of a temperature range of 2-300K and an external magnetic field of 1000Oe. figure 2 is the temperature-varying susceptibility diagram of the gadolinium borate magnetic refrigeration material. And the test is carried out in the temperature range of 2-10K and the magnetic field of 0-7T. image 3 is the magnetic entropy change diagram of the gadolinium borate magnetic refrigeration material.

[0033] figure 2 shows that at room temperature, the χ of the gadolinium borate magnetic refrigeration material M T value is 7.62cm 3 mol -1 K, with 1 uncoupled Gd calculated according to Curie's theorem 3+ The χ obtained by the ion M Theoretical value of T is 7.88cm 3 mol -1 K is very close. In the temperature range of 300 ~ 100K, as the temperature drops χ M There is almost no change in the T value, below 100K, χ M ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com