High-throughput preparation method for LaFeSi-based magnetic refrigeration material

A magnetic refrigeration material and high-throughput technology, applied in manufacturing tools, heat treatment equipment, casting molding equipment, etc., can solve the problems of long production cycle, low efficiency of preparation method, unreliable comparison results, etc., and achieve good magnetocaloric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

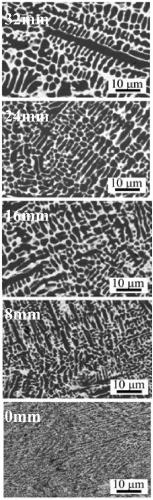

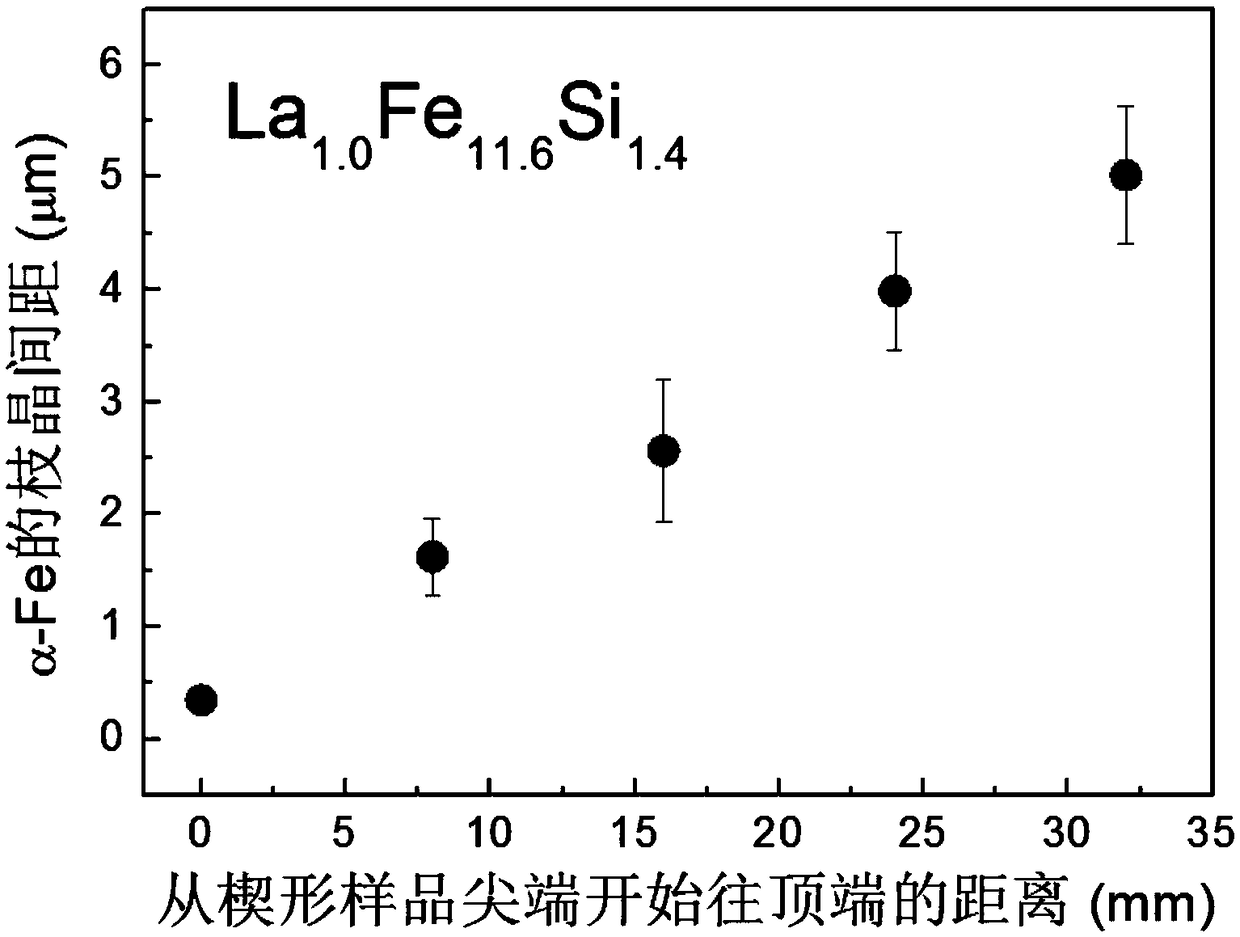

[0040] In this embodiment, the molecular formula of the LaFeSi-based magnetic refrigeration alloy material is LaFeSi 11.6 Si 1.4 .

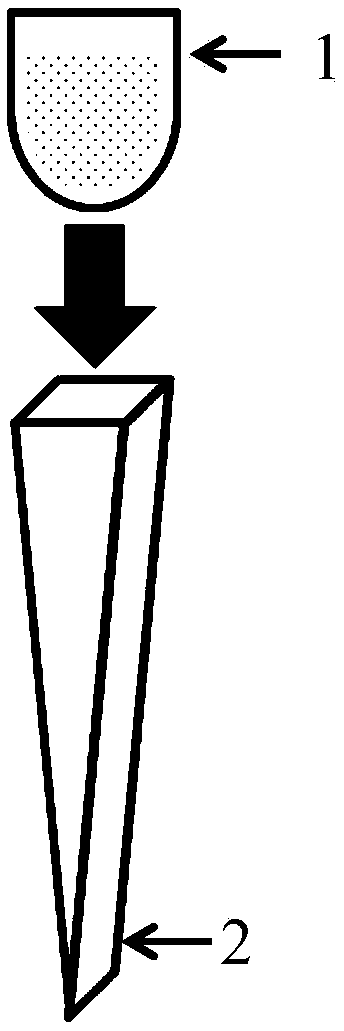

[0041] The high-throughput preparation method of the above-mentioned LaFeSi-based magnetic refrigeration material is as follows:

[0042] Step 1: According to the molecular formula LaFe 11.6 Si 1.4 Raw materials La, Fe, and Si are batched, specifically: the alloy atomic percentage is converted into mass percentage, and La, Fe, and Si are weighed in proportion, and the purity of each raw material is greater than 99%;

[0043] Step 2: Put the raw materials prepared in step 1 into the electric arc melting furnace, and vacuum the furnace body to 1×10 -5 ~5×10 -5 After the mbar is filled with argon until the pressure is 400-800mbar, the raw material is heated and smelted. After the raw material is completely melted, the smelting is continued for 2-10 minutes, and then cooled until solidified. Repeat smelting for 3 to 5 times to obtain an alloy i...

Embodiment 2

[0055] In this embodiment, the molecular formula of the LaFeSi-based magnetic refrigeration alloy material is La 1.7 Fe 11.6 Si 1.4 .

[0056] The preparation method of the above-mentioned LaFeSi-based magnetic refrigeration material is as follows:

[0057] Step 1: According to the molecular formula La 1.7 Fe 11.6 Si 1.4 Raw materials La, Fe, and Si are batched, specifically: the alloy atomic percentage is converted into mass percentage, and La, Fe, and Si are weighed in proportion, and the purity of each raw material is greater than 99%;

[0058] Step 2: Put the raw materials prepared in step 1 into the discharge arc melting furnace, and evacuate the furnace body to 1×10 -5 ~5×10 - 5 After mbar, fill with argon until the pressure is 400-800mbar, heat and melt the raw material, after the raw material is completely melted, continue to smelt for 2-10 minutes, then cool to solidify, quickly turn it over and repeat the smelting for 3-5 times to obtain a uniform composition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com