La(Fe,Si)13 based magnetic refrigeration material by taking high-Ce industrial pure mixed rare earth as raw material as well as preparation method and application thereof

A technology of magnetic refrigeration materials and mixed rare earths, which can be used in heat exchange materials, chemical instruments and methods, etc., and can solve the problems of increasing hysteresis loss and increasing the magnitude of magnetocaloric effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

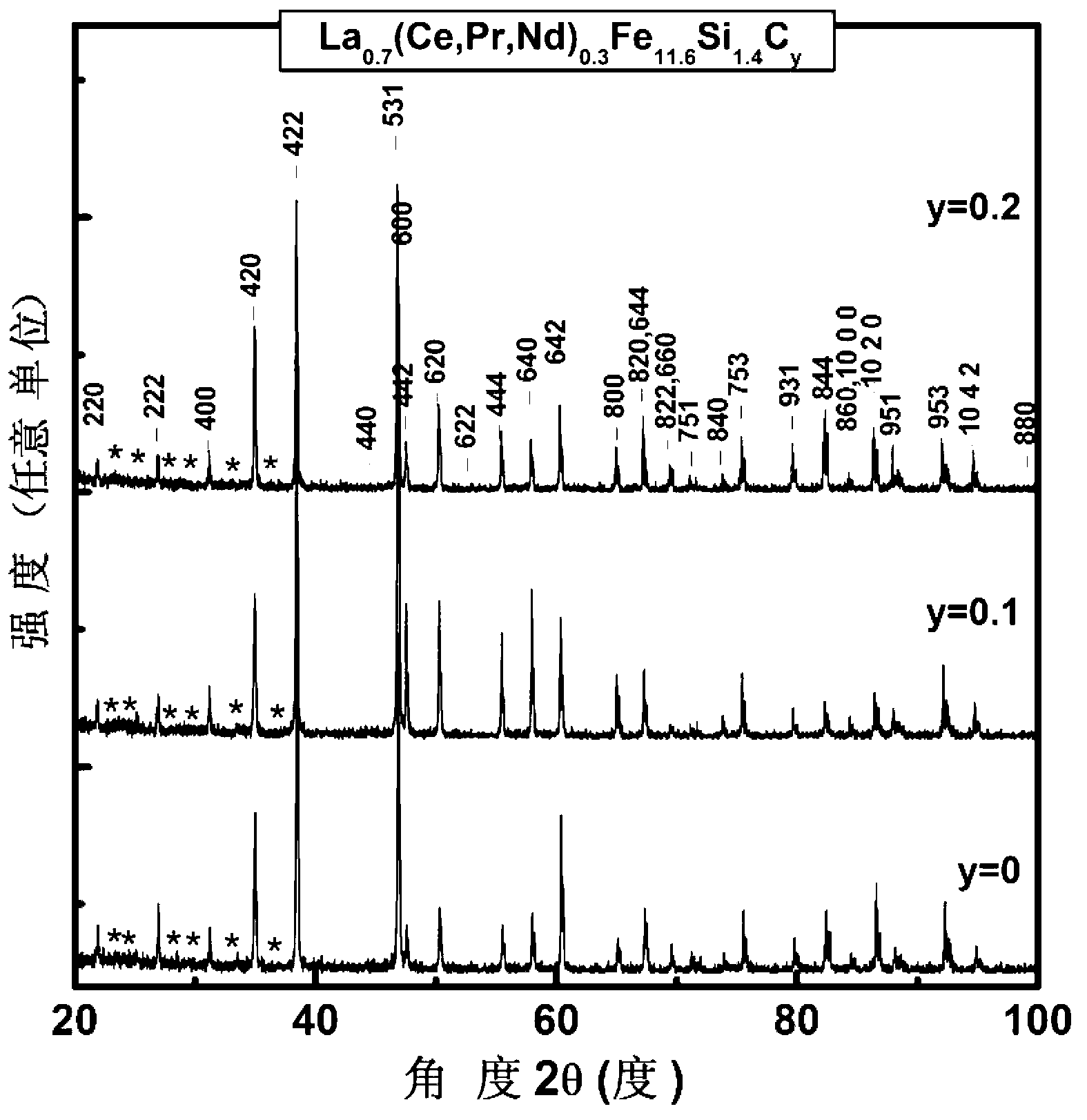

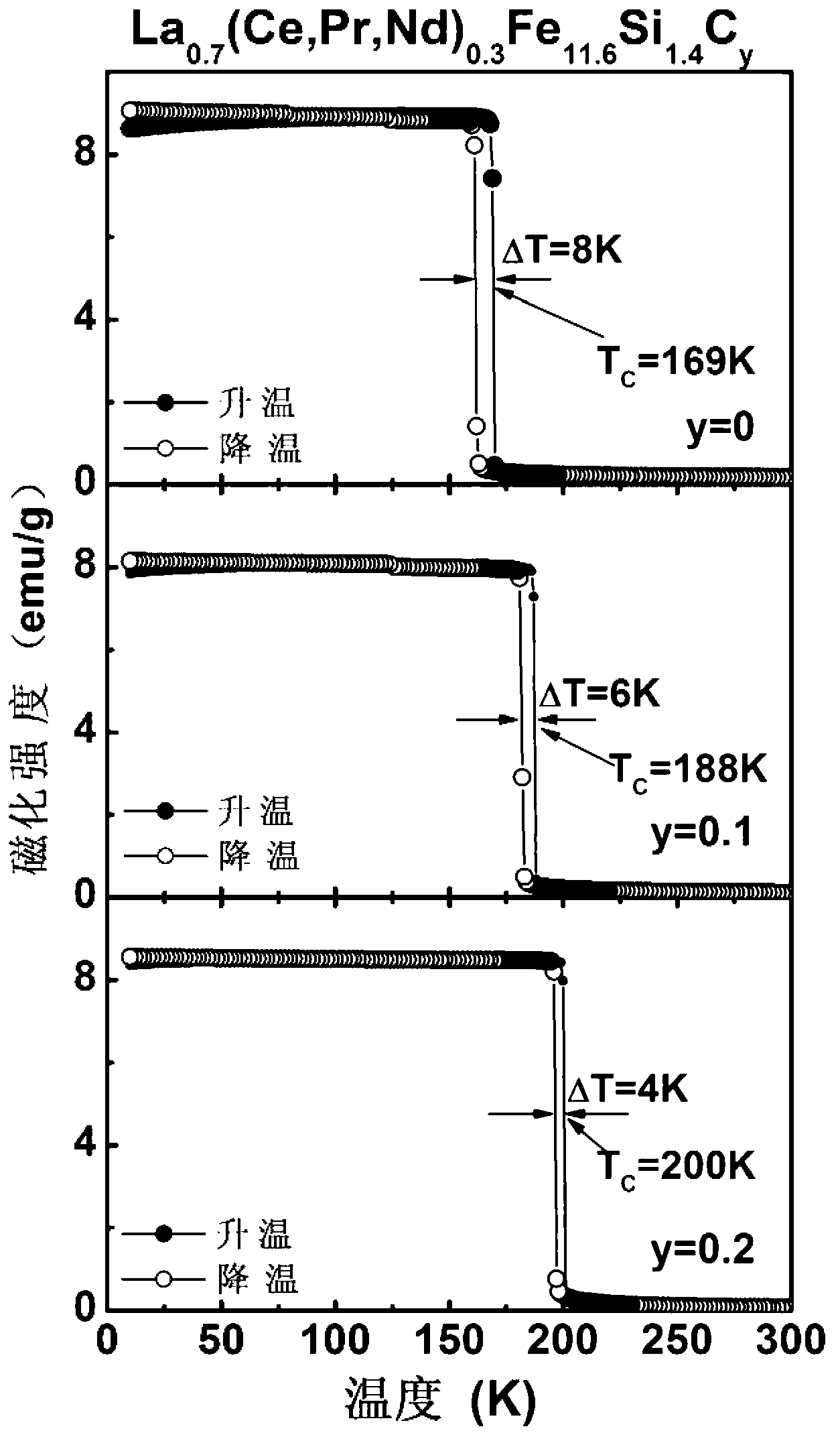

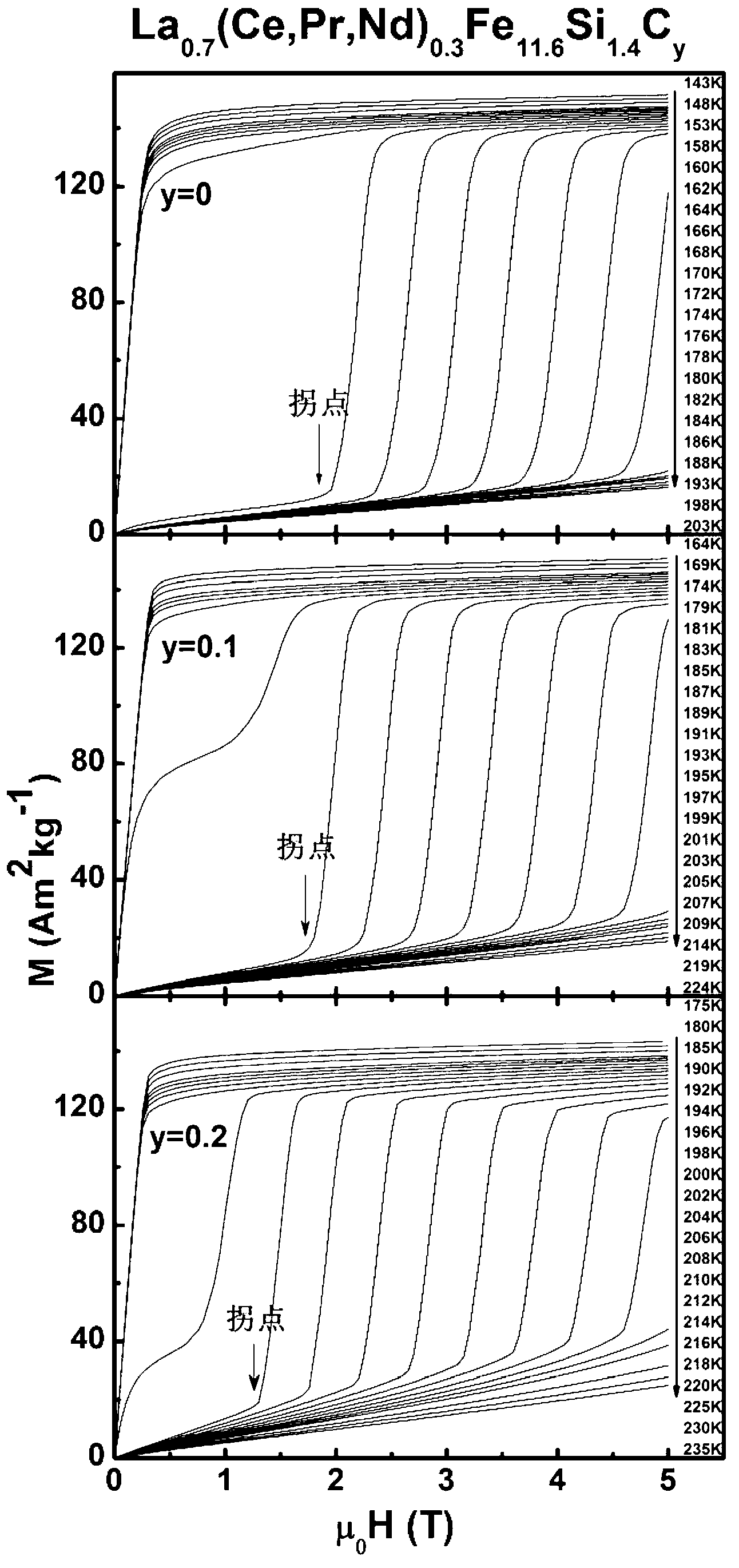

[0078] Embodiment 1: prepare La 0.7 (Ce,Pr,Nd) 0.3 Fe 11.6 Si 1.4 C y (y=0,0.1,0.2) Three kinds of magnetic refrigeration Material

specific example

[0079] This embodiment provides to prepare La by chemical formula 0.7 (Ce,Pr,Nd) 0.3 Fe 11.6 Si 1.4 C y (y=0, 0.1, 0.2) specific examples of magnetic refrigeration materials, the preparation process is:

[0080] 1) Press La 0.7 (Ce,Pr,Nd) 0.3 Fe 11.6 Si 1.4 C y (y=0, 0.1, 0.2) chemical formula ingredients, the raw materials are high Ce industrial pure mixed rare earth La-Ce-Pr-Nd, elemental Fe, elemental Si, elemental La and FeC alloy, among which, elemental La is used to supplement the mixed rare earth In the part where La is insufficient, FeC alloy is used to provide C. Since FeC alloy also contains Fe element, it is necessary to appropriately reduce the added elemental Fe, so that the ratio of various elements added still meets the atomic ratio in the chemical formula;

[0081] 2) Mix the raw materials in step 1), put them into the electric arc furnace, and evacuate to 2×10 -3 Pa, clean the furnace chamber twice with high-purity argon gas with a purity of 99.996wt...

Embodiment 2

[0089] Embodiment 2: prepare La 0.7 (Ce,Pr,Nd) 0.3 (Fe 1-x co x ) 11.6 Si 1.4 (x=0.02,0.04,0.06, 0.08, 0.1) five magnetic refrigeration materials

[0090] This embodiment provides to prepare La by chemical formula 0.7 (Ce,Pr,Nd) 0.3 (Fe 1-x co x ) 11.6 Si 1.4 (x=0.02, 0.04, 0.06, 0.08, 0.1) Specific examples of magnetic refrigeration materials, the preparation process is:

[0091] 1) Press La 0.7 (Ce,Pr,Nd) 0.3 (Fe 1-x co x ) 11.6 Si 1.4(x=0.02, 0.04, 0.06, 0.08, 0.1) chemical formula ingredients, raw materials are high Ce industrial pure mixed rare earth La-Ce-Pr-Nd, and elemental Fe, elemental Co, elemental Si and elemental La, among which elemental La is used To supplement the insufficient part of La in the mixed rare earth;

[0092] 2) Mix the raw materials in step 1), put them into the electric arc furnace, and evacuate to 2×10 -3 Pa, clean the furnace chamber twice with high-purity argon gas with a purity of 99.996wt.%, then f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com