Manganese-cobalt-germanium-base alloy magnetic refrigeration material and preparing method thereof

A technology of magnetic refrigeration materials and base alloys, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., to achieve the effect of easy implementation, wide application prospects and avoiding thermal hysteresis problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

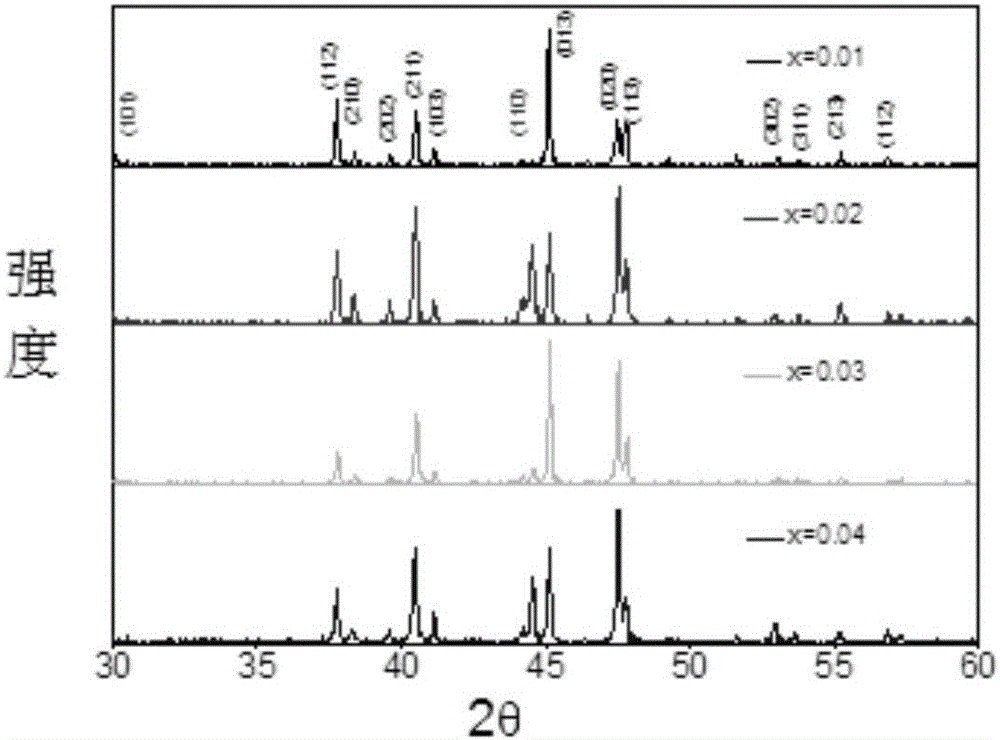

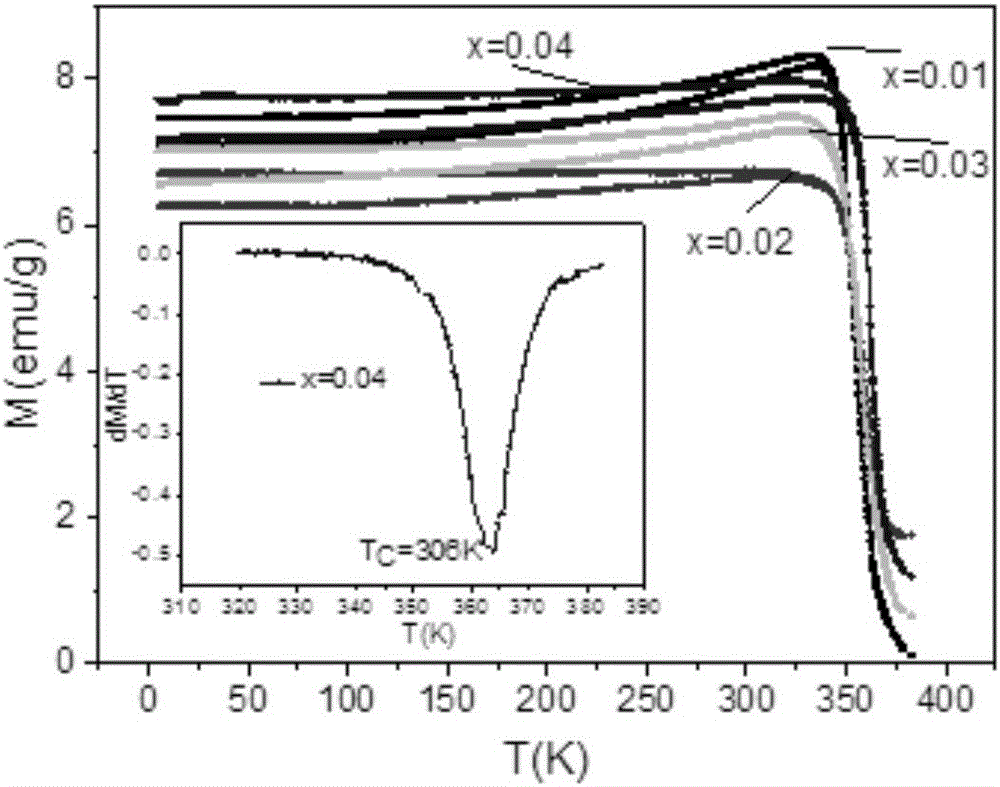

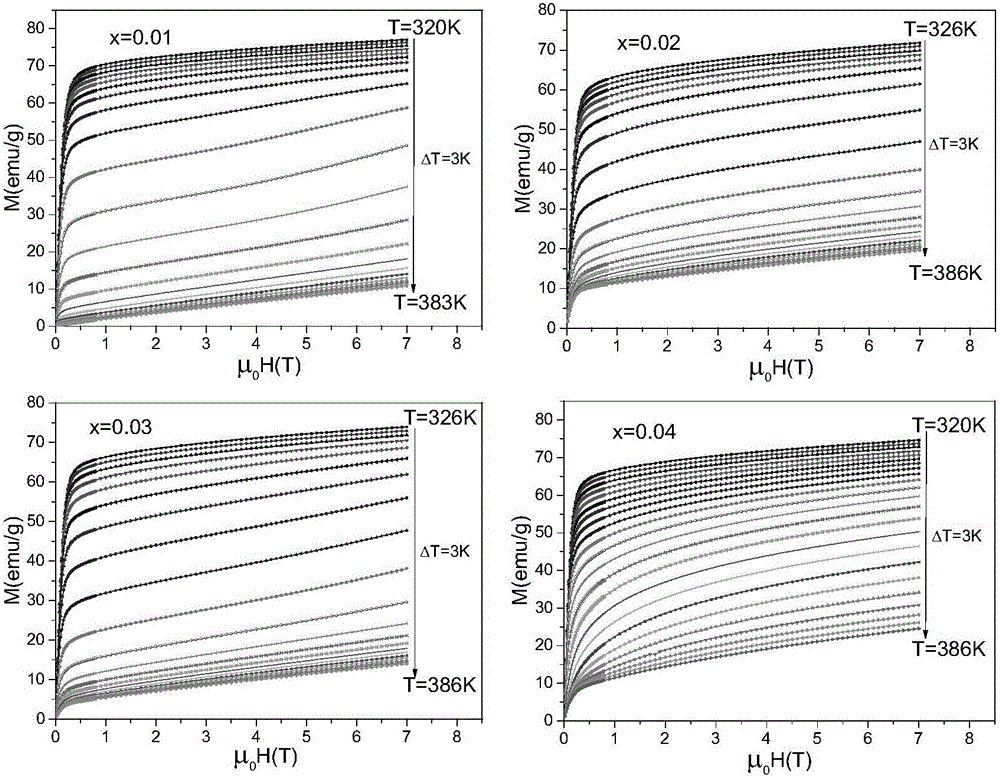

Embodiment 1

[0026] According to the molar ratio of 1:1:0.99:0.01, the purity of 99.9% Mn, 99.9% Co, 99.99% Ge, and 99.9% Cu is weighed and placed in a vacuum electric arc furnace for melting. Below 5Pa, turn on the molecular pump to evacuate again to below 10 -4 Pa, pass high-purity argon gas (99.999%) with a pressure of 10Pa, repeat the above operation steps twice, start a fire with a current of 30A, the distance between the electrode and the sample is about 0.5cm, slowly adjust the current to 80A until the sample is completely melted, and then Reduce the current to 60A and smelt for half a minute, wait for the alloy to cool and turn it over, and repeat the smelting four times to ensure that the samples are evenly mixed. Take out the cooled sample and put it into a high-purity high-temperature-resistant quartz glass test tube, use a high-vacuum molecular pump system to evacuate to less than 5Pa, fill it with high-purity argon (99.999%) for washing, repeat the above steps three times, sea...

Embodiment 2

[0028] All are the same except that the molar addition ratio between Mn, Co, Ge and Cu is 1:1:0.98:0.02.

Embodiment 3

[0030] All are the same except that the molar addition ratio between Mn, Co, Ge and Cu is 1:1:0.97:0.03.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com