Method for preparing orthorhombic black phosphors monocrystals at low pressure

An orthorhombic, black phosphorus technology, applied in the field of optoelectronic semiconductor two-dimensional materials, can solve the problems of reduced black phosphorus purity, limited application, higher requirements for temperature control and red phosphorus raw materials, etc., to reduce the reaction time and optimize the reaction. temperature, the effect of simplifying the heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

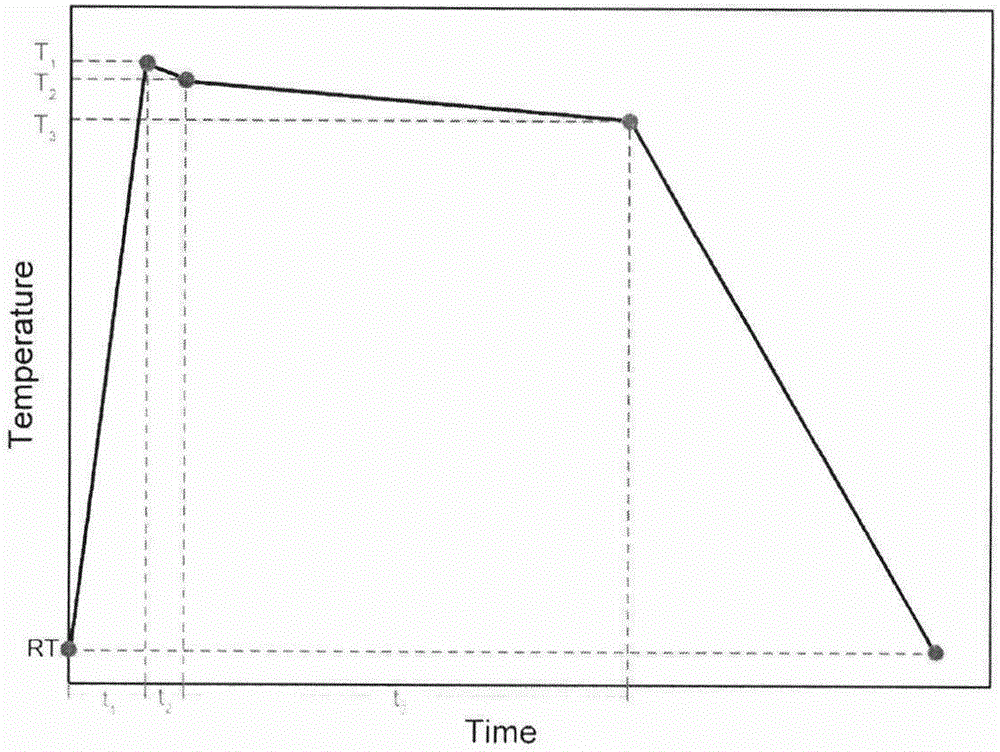

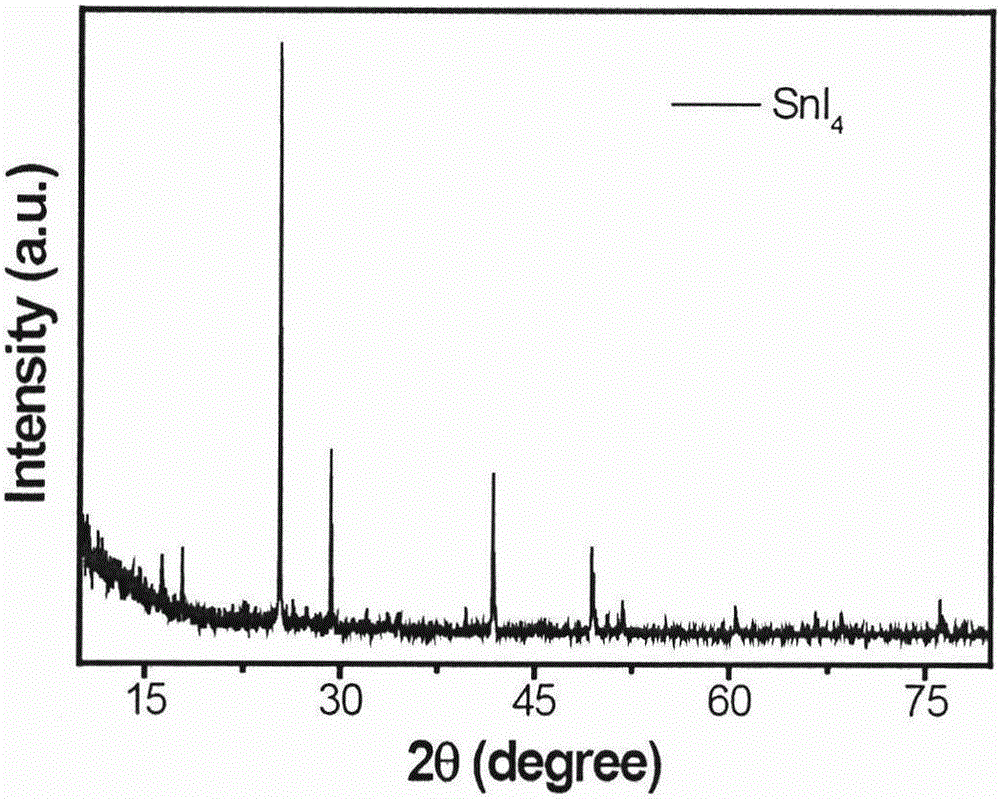

[0014] The invention provides a method for preparing black phosphorus single crystal, wherein the method comprises: mixing phosphorus raw material, elemental Sn, and mineralizer Sn14, placing them in a quartz tube, vacuumizing and sealing at high temperature, and placing the sealed quartz tube in a In a Furnace, black phosphorus is prepared through a process of programmed heating and cooling. In the process of temperature programming, firstly, time t elapses from room temperature 1 Warming up to the sublimation temperature T 1 , after time t 2 down to the initial crystallization temperature T 2 , the elapsed time t 3 reaches the crystallization termination temperature T 3 . where time t 1 , t 2 Not limited, T 1 above 450°C, preferably T 1 Higher than 535°C; time t 3 Relatively long, greater than 4 hours, T 3 greater than 416°C, preferably, T 3 Greater than 450°C; T 3 The process of lowering the temperature to room temperature is not limited, and it can be realized...

Embodiment 1

[0020] Add 1g of red phosphorus, 0.05g of tin, and 0.01g of tin iodide into the glass quartz tube, then vacuumize the quartz tube, and seal the quartz tube (inner diameter 1cm, length 10cm) when the vacuum reaches 1Pa. Then set the following heating program in the muffle furnace: room temperature-60min-650°C-120min-650°C-480min-500°C-room temperature.

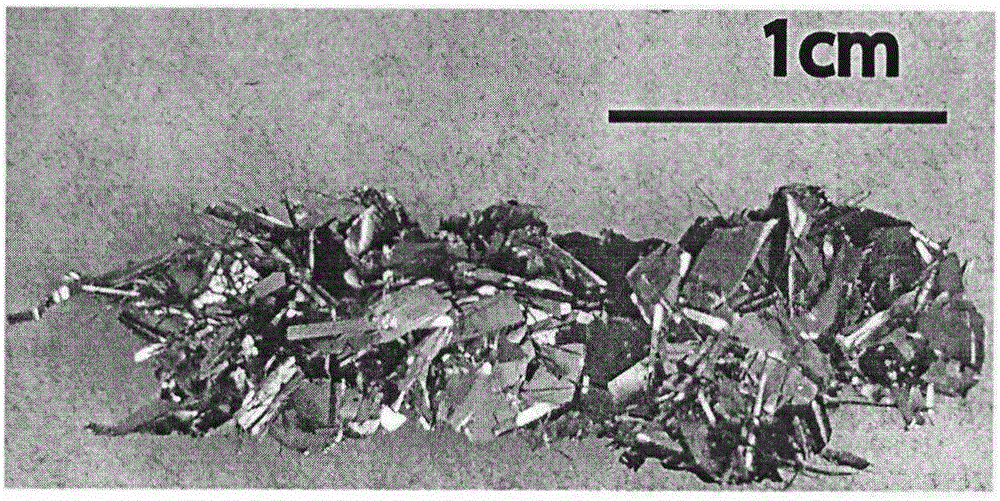

[0021] The obtained black phosphorus has a conversion rate of 80% and is in the form of a block with a size of 0.8 cm×0.8 cm.

Embodiment 2

[0023] Add 2g of red phosphorus, 0.1g of tin, and 0.01g of tin iodide into the glass quartz tube, and then vacuumize the quartz tube. When the vacuum reaches 1Pa, package the quartz tube (inner 2cm, length 10cm). Then set the following heating program in the muffle furnace: room temperature-10min-450°C-120min-450°C-480min-416°C-room temperature.

[0024] The conversion rate of the obtained black phosphorus was 64.3%, which was in block shape with a small amount of flakes, and the size was 1.6cm×1.2cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com