Vertical tuned mass magnetic lead screw type inerter eddy current damper

A technology of magnetic screw and tuning quality, applied in the direction of magnetic spring, shock absorber, spring/shock absorber, etc., can solve the problem of large physical mass of TMD, large static elongation of spring, friction of ball screw type inerter, etc. problems, to achieve the effect of easy modular assembly, lightening of physical counterweight, and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

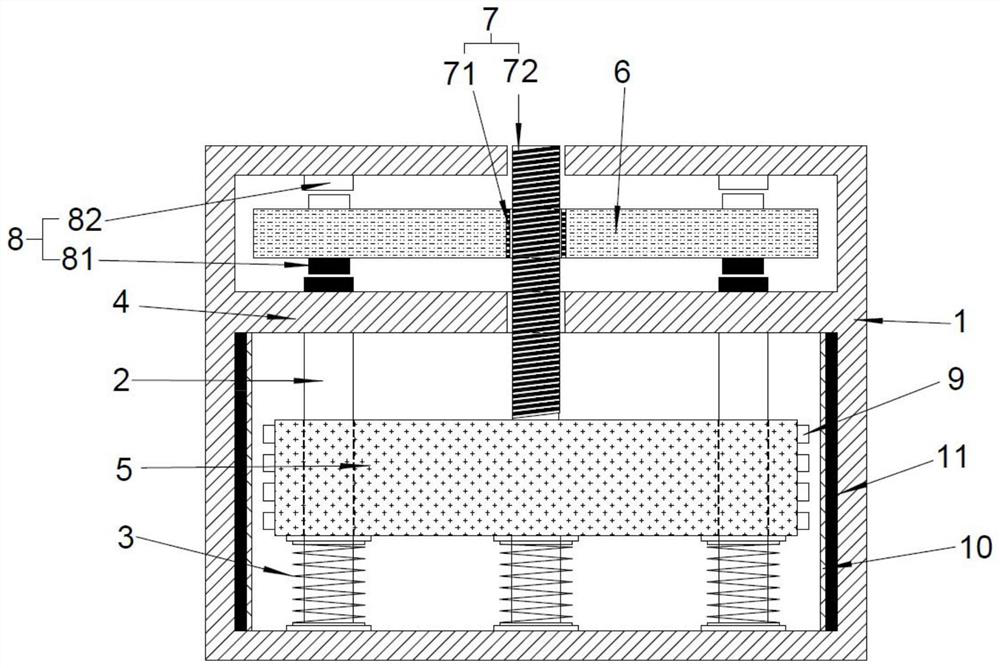

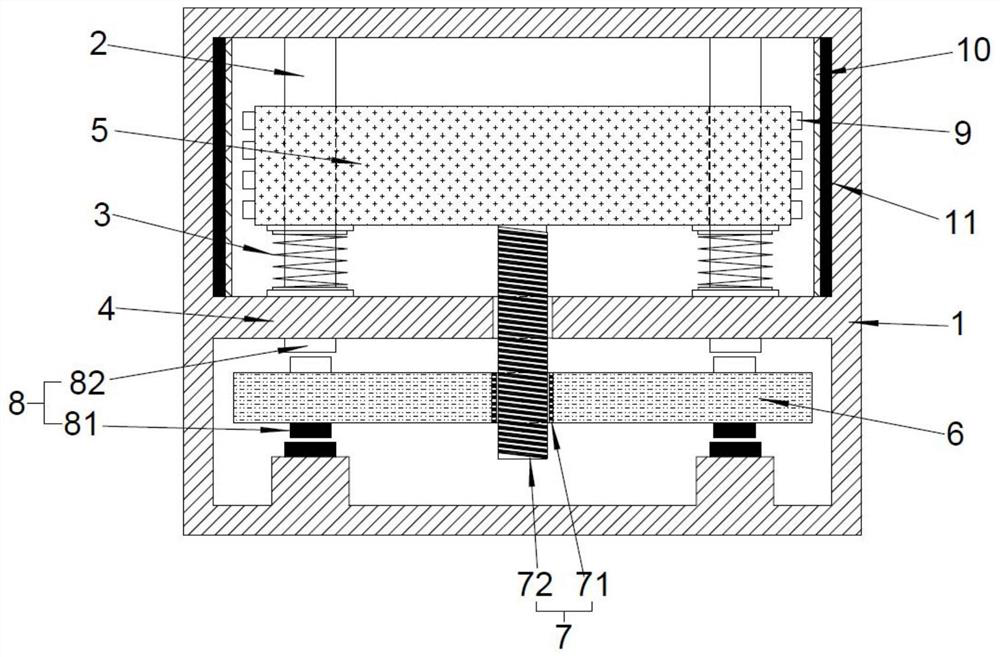

[0053] Such as figure 1 with 2 Shown is a vertically tuned mass magnetic force screw type inertial eddy current damper, including a spring-mass system, an inertial mass system, an eddy-current damping system and a support system.

[0054] The spring mass system includes a spring (3) and a counterweight (5), the counterweight (5) is in the shape of a cuboid, and a hole larger than the diameter of the guide rod (2) is left on it, so that the counterweight (5) ) is sleeved on the guide rod (2) and can move linearly along it; the spring (3) is sleeved on the guide rod (2), one end is fixed with the counterweight (5), and the other end is connected with the outer frame (1) or the support The bracket (4) is consolidated.

[0055] The inertial mass system includes a flywheel (6), a magnetic screw nut pair (7) and a magnetic suspension thrust bearing (8). The flywheel (6) is sleeved on the magnetic lead screw (72) and the magnetic nut (71) of the magnetic lead screw nut pair (7), a...

Embodiment 2

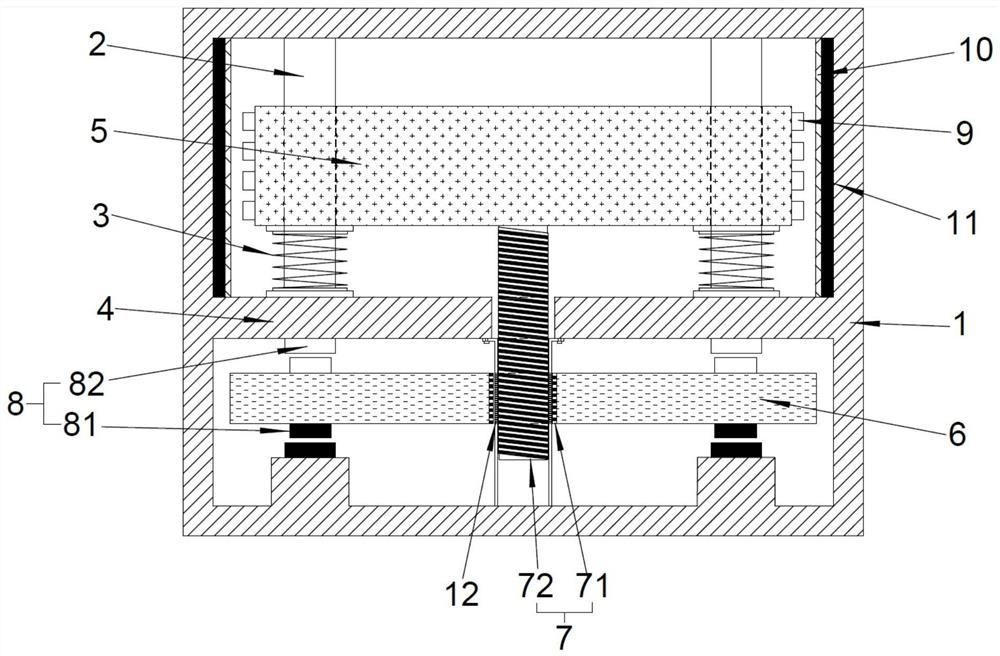

[0059] Such as image 3 with 4 Shown is a vertically tuned mass magnetic field modulation type magnetic screw type inertial eddy current damper, including a spring-mass system, an inertial mass system, an eddy-current damping system and a support system.

[0060] The spring mass system includes a spring (3) and a counterweight (5), the counterweight (5) is in the shape of a cuboid, and a hole larger than the diameter of the guide rod (2) is left on it, so that the counterweight (5) ) is sleeved on the guide rod (2) and can move linearly along it; the spring (3) is sleeved on the guide rod (2), one end is fixed with the counterweight (5), and the other end is connected with the outer frame (1) or the support The bracket (4) is consolidated.

[0061] The inertial mass system includes a flywheel (6), a magnetic screw nut pair (7), a modulation ring (12) and a magnetic suspension thrust bearing (8). The flywheel (6) is sleeved on the magnetic lead screw (72) and the magnetic nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com