Storage battery grid

A battery and grid technology, applied in the direction of electrode carrier/current collector, etc., can solve the problems of battery grid quality, the unreasonable relationship between electrolyte density, lead-acid battery specific energy is difficult to break through, and the reaction efficiency is lower than 50%. , to achieve the effect of reducing heavy metal pollution, solving lead plaster falling off, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

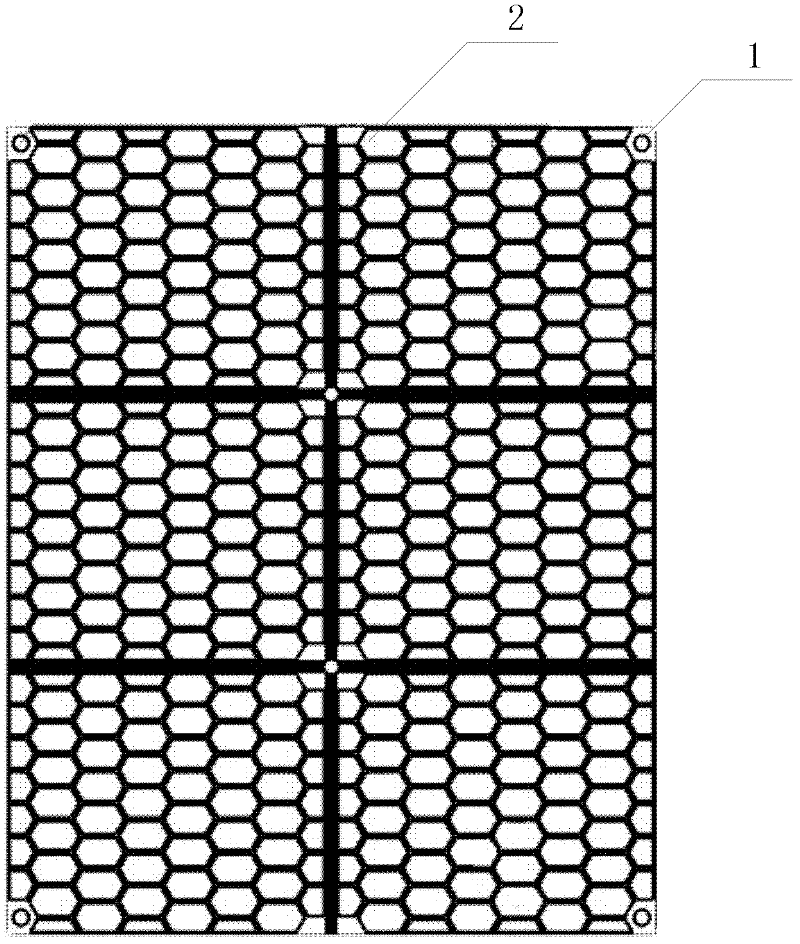

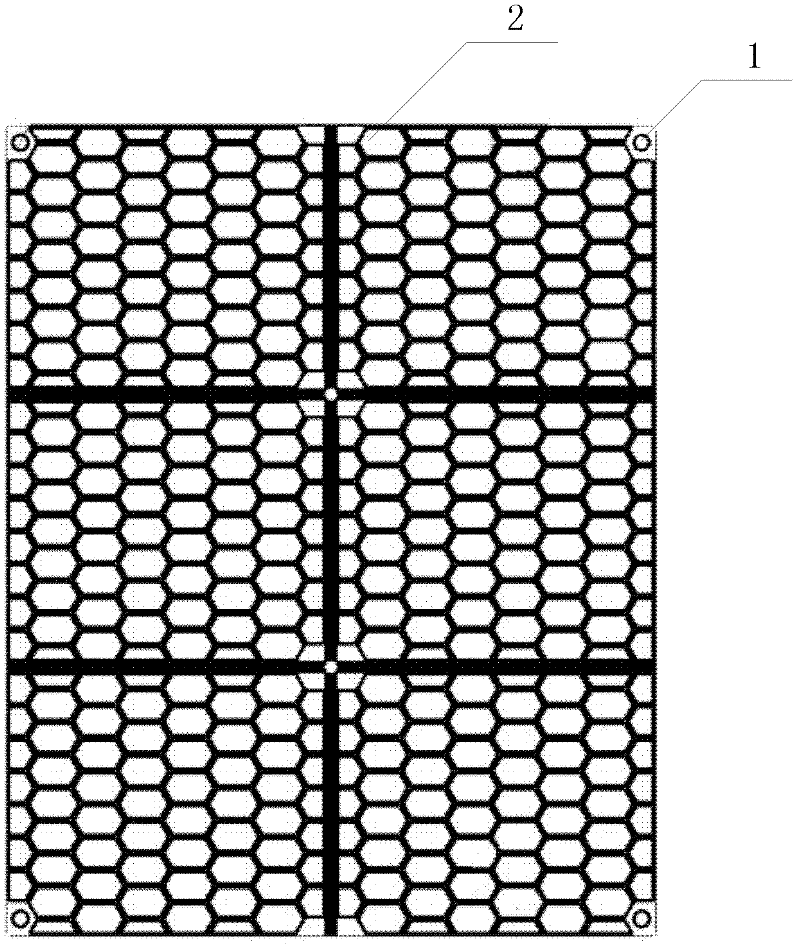

Image

Examples

Embodiment 1

[0027] As a preferred embodiment of the present invention one, by weight, the storage battery grid of the present invention contains 15 parts of conductive agent, 70 parts of ceramic composite material and 15 parts of dielectric material, and then used for storage battery, after testing, the internal resistance of storage battery is 150-200(mΩ) / m, the number of cycles at room temperature is 800-1200 times, and the fast charging time is 1-2 hours.

Embodiment 2

[0028] As preferred embodiment two of the present invention, by weight, battery grid of the present invention contains 20 parts of conductive agent, 65 parts of ceramic composite materials and 15 parts of dielectric material, is then used for storage battery, and after testing, the internal resistance of storage battery is 100-150(mΩ) / m, 800-1000 cycles at room temperature, and 1-1.5 hours for fast charging.

Embodiment 3

[0029] As preferred embodiment three of the present invention, by weight, battery grid of the present invention contains 20 parts of conductive agent, 70 parts of ceramic composite materials and 10 parts of dielectric material, is used for storage battery then, after testing, the internal resistance of storage battery is 100-150(mΩ) / m, the number of cycles at room temperature is 800-1200 times, and the fast charging time is 1-1.5 hours.

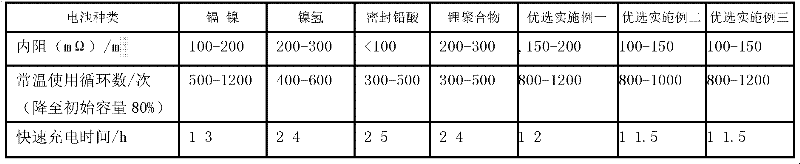

[0030] The storage battery manufactured by three preferred embodiments of the present invention is compared with other types with the same capacity storage battery as shown in the table below:

[0031]

[0032]It can be seen from the above table that compared with other types of storage batteries with the same capacity, the internal resistance, cycle times at normal temperature and fast charging time of the storage battery using the grid of the present invention are all improved.

[0033] As the content of the conductive agent increases, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com