High-mobility ratio aluminum-doped zinc oxide transparent conductive thin film and preparation method thereof

A technology of aluminum-doped zinc oxide and transparent conductive films, which is applied in the direction of oxide conductors, conductive layers on insulating carriers, non-metallic conductors, etc., can solve the problem of low mobility of AZO transparent conductive films, long processing time, Low mobility and other issues, to achieve the effect of improving photoelectric conversion efficiency, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

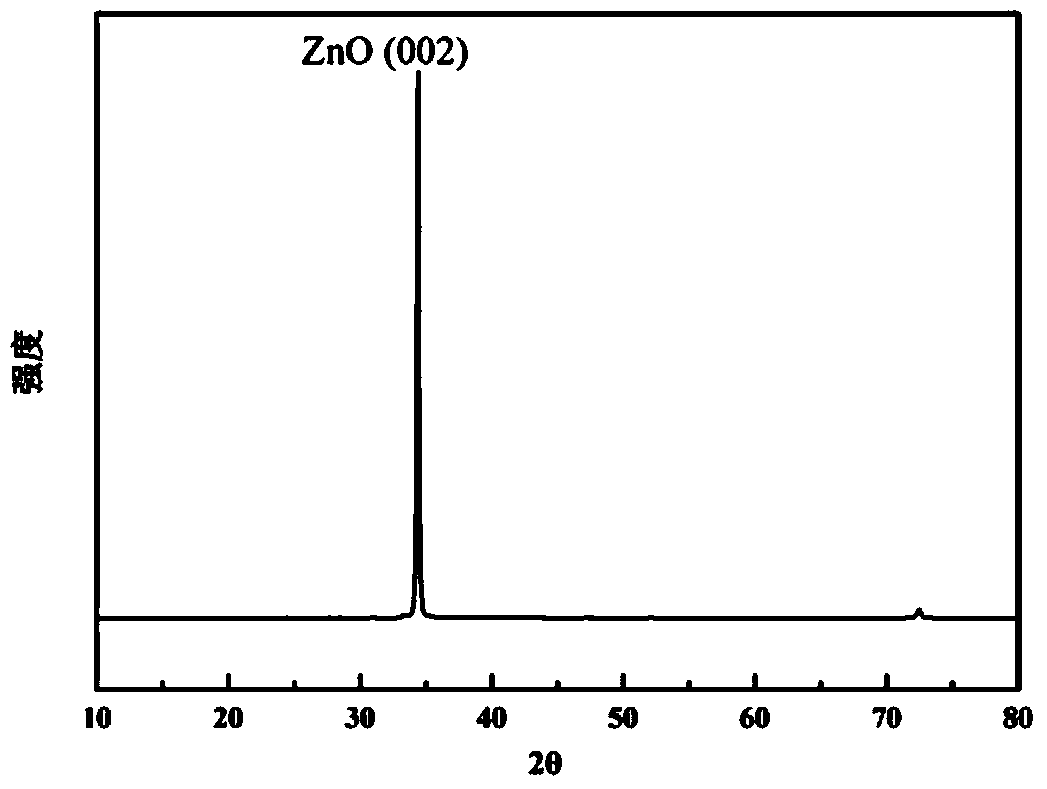

[0037] The AZO ceramic target with a mass ratio of aluminum oxide to zinc oxide of 0.008:1 was selected as the seed layer AZO target, and a 50nm thick AZO seed layer was deposited on the damp white glass by DC magnetron sputtering. The sputtering conditions were: The sheet temperature is 350°C, the sputtering power is 200W, the sputtering time is 8 minutes, the sputtering gas is high-purity (purity greater than 99.999%) argon (that is, the volume ratio of oxygen to argon is 0:1), the gas flow rate It is 30sccm, and the working pressure is 0.4Pa.

[0038] Then select the AZO ceramic target with a mass ratio of aluminum oxide to zinc oxide of 0.005:1 as the AZO target for the main layer, and deposit an AZO main layer with a thickness of 1200 nm on the AZO seed layer by DC magnetron sputtering, that is, Deposited AZO transparent conductive film, the sputtering conditions are: the substrate temperature is 350°C, the sputtering power is 200W, the sputtering time is 50 minutes, and ...

Embodiment 2

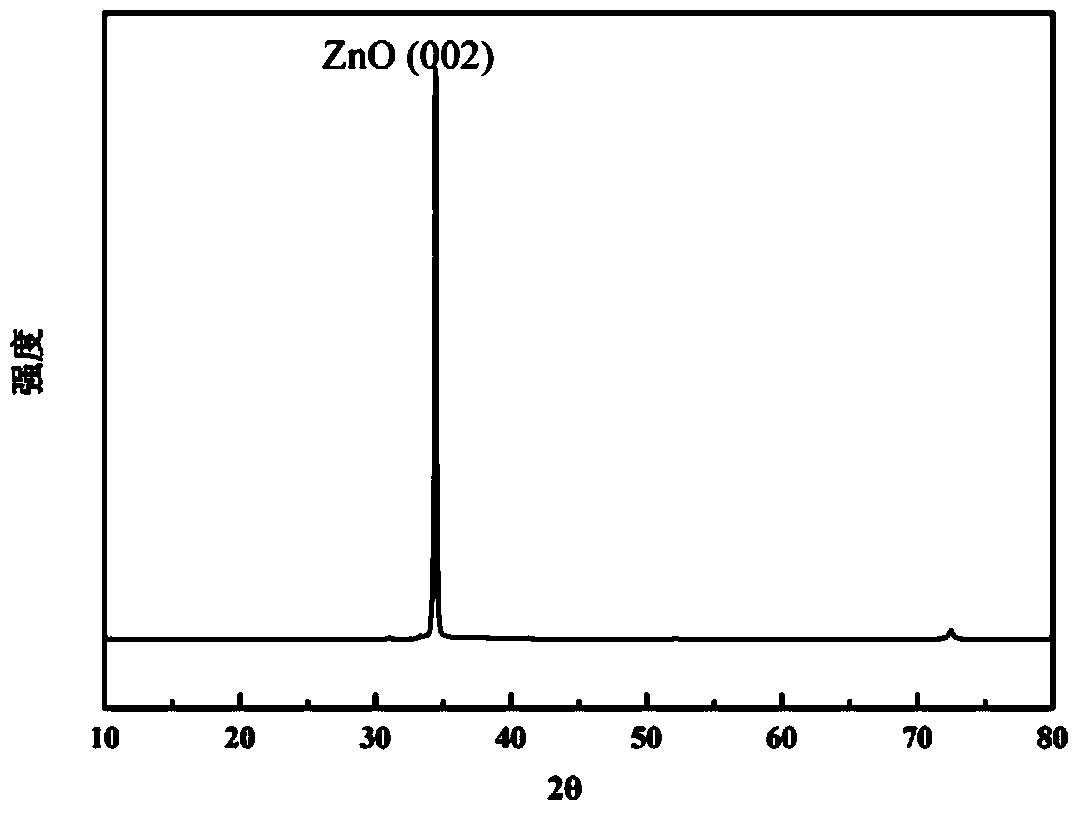

[0044] The AZO ceramic target with a mass ratio of alumina to zinc oxide of 0.008:1 was selected as the AZO target for the seed layer, and a 130nm-thick AZO seed layer was deposited on ultra-white glass by DC magnetron sputtering. The sputtering conditions were: The substrate temperature is 350°C, the sputtering power is 200W, and the sputtering time is 8 minutes. The sputtering gas is a mixed gas of high-purity (purity greater than 99.999%) argon and high-purity (purity greater than 99.999%) oxygen. The volume ratio of argon is 1:2, the gas flow rate is 30sccm, and the working pressure is 0.4Pa.

[0045] Then choose the AZO ceramic target with a mass ratio of aluminum oxide to zinc oxide of 0.005:1 as the AZO target for the main layer, and deposit an AZO main layer with a thickness of 1230 nm on the AZO seed layer by DC magnetron sputtering, that is, Deposited AZO transparent conductive film, the sputtering conditions are: the substrate temperature is 350°C, the sputtering po...

Embodiment 3

[0057] The AZO ceramic target with a mass ratio of alumina to zinc oxide of 0.008:1 was selected as the AZO target for the seed layer, and a 150nm-thick AZO seed layer was deposited on ultra-white glass by DC magnetron sputtering. The sputtering conditions were: The substrate temperature is 350°C, the sputtering power is 200W, and the sputtering time is 8 minutes. The sputtering gas is a mixed gas of high-purity (purity greater than 99.999%) argon and high-purity (purity greater than 99.999%) oxygen. The volume ratio of argon is 1:9, the gas flow rate is 30sccm, and the working pressure is 0.4Pa.

[0058]Then select the AZO ceramic target with a mass ratio of aluminum oxide to zinc oxide of 0.005:1 as the AZO target for the main layer, and deposit an AZO main layer with a thickness of 1210 nm on the AZO seed layer by DC magnetron sputtering, that is, The AZO transparent conductive thin film of deposited state, sputtering condition is: substrate temperature is 350 ℃, and sputte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Mobility | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com