Molding method for graphene modified epoxy resin fiber wound shell

A technology of epoxy resin fiber and graphene modification, which is applied in the directions of household components, applications, household appliances, etc., to achieve the effect of improving the fiber strength, the blasting strength, and the blasting strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

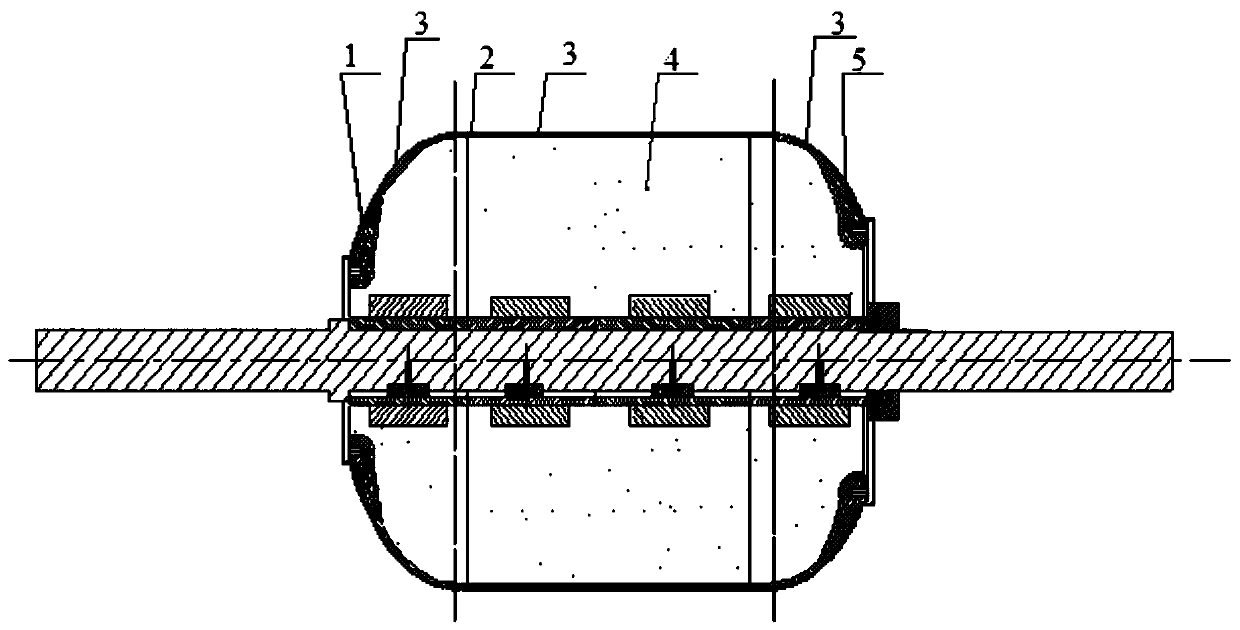

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0019] The molding method of a kind of graphene modified epoxy resin fiber wound casing that the present invention relates to, it comprises the following steps:

[0020] Step 1: modify graphene oxide, adopt silane coupling agent and diluent to carry out surface modification to graphene oxide (graphene is grafted by above-mentioned material, make modified graphene and epoxy resin better Compatible with each other, and further obtain a high-performance resin formula that meets the requirements of manufacturability);

[0021] Step 2: use the modified graphene oxide to strengthen the epoxy resin to obtain a reinforced epoxy resin (fully develop the characteristics of graphene, strengthen the epoxy resin, and improve the performance of the epoxy resin);

[0022] Step 3: Carry out the integral molding of the rocket launch case, the rocket launch case includes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com