Integral forming method for engine composite shell and spray pipe

A technology of composite materials and molding methods, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of large negative weight, long cycle, complicated manufacturing and assembly process, etc., to improve the quality ratio, improve the use performance, eliminate The effect of the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

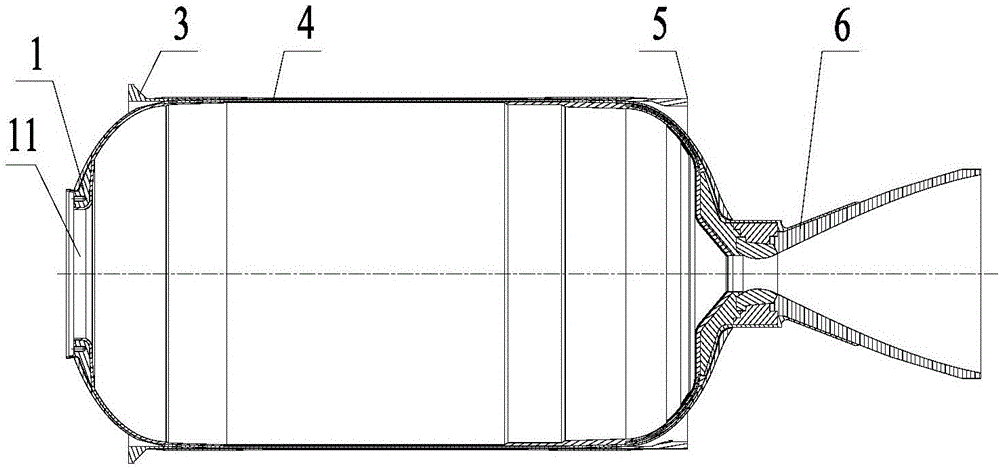

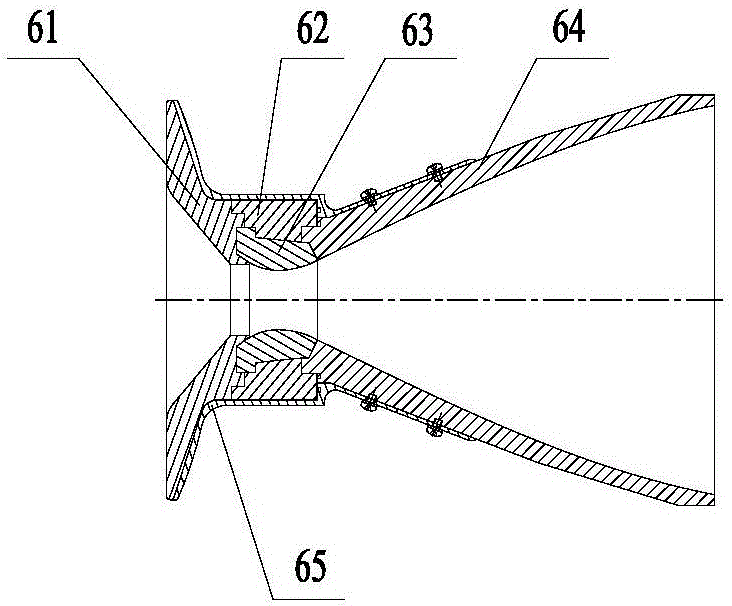

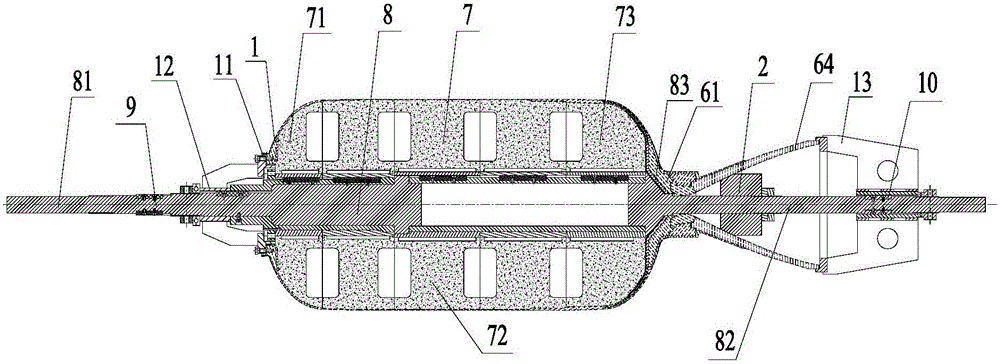

[0028] 1) Form the nozzle 6, the front joint 1, the front skirt 3, the rear skirt 5, the water-soluble quartz sand mandrel 7 and the mandrel 8 respectively, wherein: the outer surface of the water-soluble quartz sand mandrel 7 and the engine composite material shell The internal profile is consistent, and the nozzle 6 includes a converging section 61, a backing 62, a throat lining 63, a diffusing section 64 and a nozzle housing 65;

[0029] In this embodiment, the water-soluble quartz sand mandrel 7 is prepared with a quartz sand mixed adhesive according to the weight ratio of quartz sand, polyvinyl alcohol and water in a ratio of 100:4:8, and is cured to obtain the water-soluble quartz sand mandrel 7; the front joint 1 The material of nozzle housing 65 is aluminum alloy forging material or titanium alloy forging material; the throat liner 63 of nozzle 6 is made of C / C composite material, and the convergent section 61, diffusion section 64, back of nozzle 6 The materials used ...

Embodiment 2

[0039] 1) Form the nozzle 6, the front joint 1, the front skirt 3, the rear skirt 5, the water-soluble quartz sand mandrel 7 and the mandrel 8 respectively, wherein: the outer surface of the water-soluble quartz sand mandrel 7 and the engine composite material shell The internal profile is consistent, and the nozzle 6 includes a converging section 61, a backing 62, a throat lining 63, a diffusing section 64 and a nozzle casing 65;

[0040] In this embodiment, the water-soluble quartz sand mandrel 7 is prepared with a quartz sand mixed adhesive according to the weight ratio of quartz sand, polyvinyl alcohol and water in a ratio of 100:5:8, and is solidified to obtain the water-soluble quartz sand mandrel 7; the front joint 1 The material of nozzle housing 65 is aluminum alloy forging material or titanium alloy forging material; the throat liner 63 of nozzle 6 is made of C / C composite material, and the convergent section 61, diffusion section 64, back of nozzle 6 The materials u...

Embodiment 3

[0050] 1) Form the nozzle 6, the front joint 1, the front skirt 3, the rear skirt 5, the water-soluble quartz sand mandrel 7 and the mandrel 8 respectively, wherein: the outer surface of the water-soluble quartz sand mandrel 7 and the engine composite material shell The internal profile is consistent, and the nozzle 6 includes a converging section 61, a backing 62, a throat lining 63, a diffusing section 64 and a nozzle housing 65;

[0051] In this embodiment, the water-soluble quartz sand mandrel 7 is prepared with a quartz sand mixed adhesive according to the weight ratio of quartz sand, polyvinyl alcohol and water in a ratio of 100:3:8, and is solidified to obtain the water-soluble quartz sand mandrel 7; the front joint 1 The material of nozzle housing 65 is aluminum alloy forging material or titanium alloy forging material; the throat liner 63 of nozzle 6 is made of C / C composite material, and the convergent section 61, diffusion section 64, back of nozzle 6 The materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com