Cage type carbon dioxide adsorption material as well as preparation method and application thereof

A carbon dioxide and adsorption material technology, applied in chemical instruments and methods, through adsorption, separation methods, etc., can solve the problems that restrict the large-scale industrial application of amine-based functionalized solid adsorption materials, complex preparation processes, and high material costs, and achieve regeneration. Low energy consumption, improved adsorption capacity, and the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

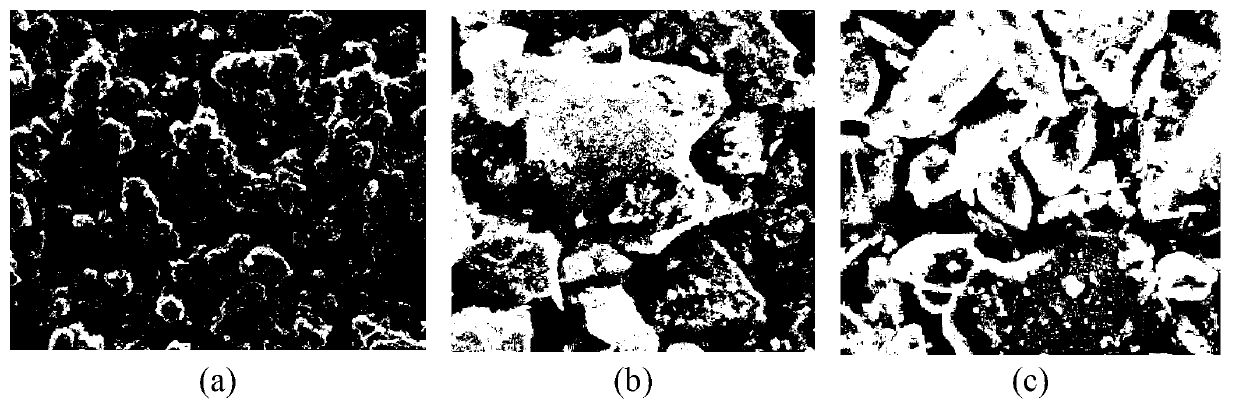

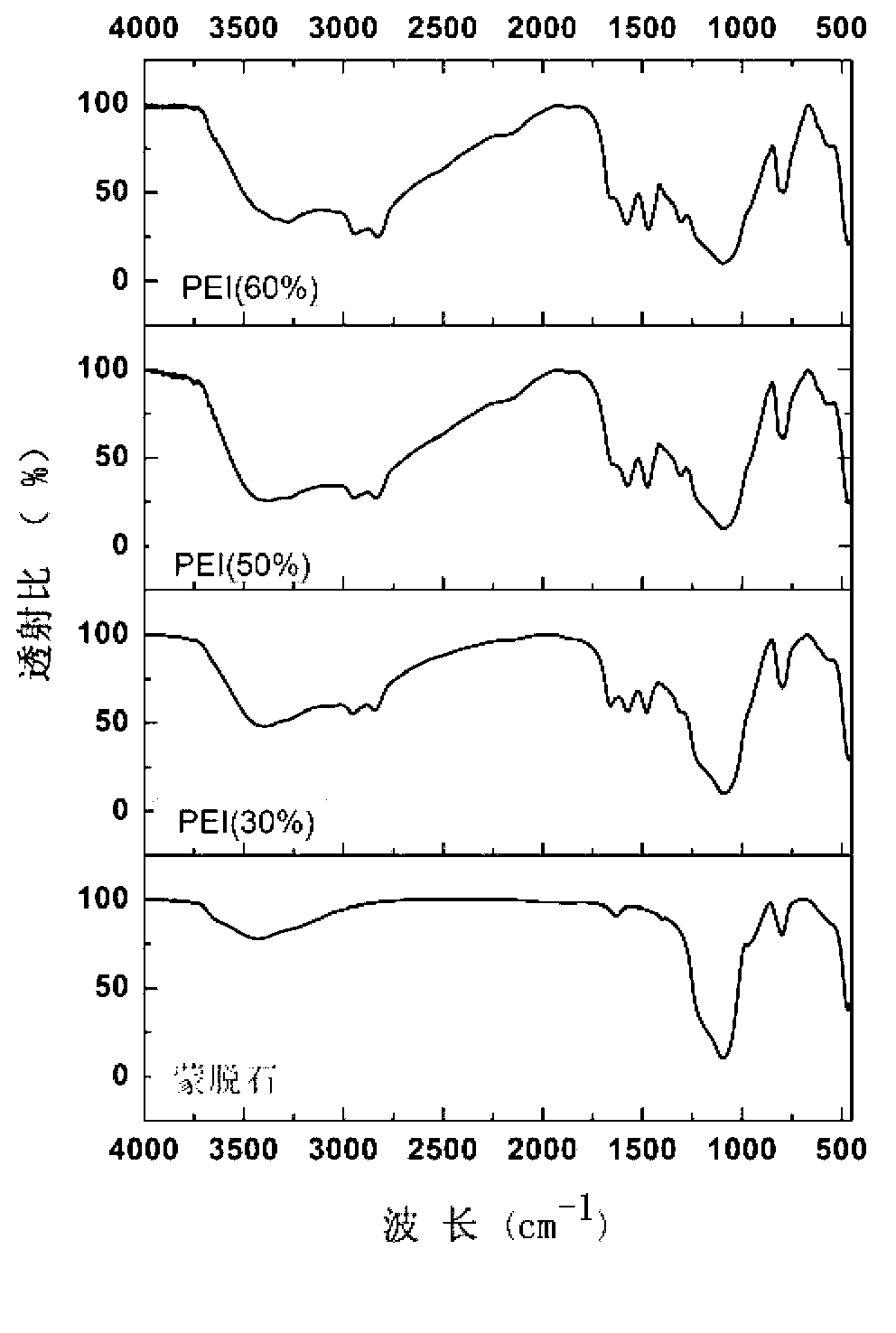

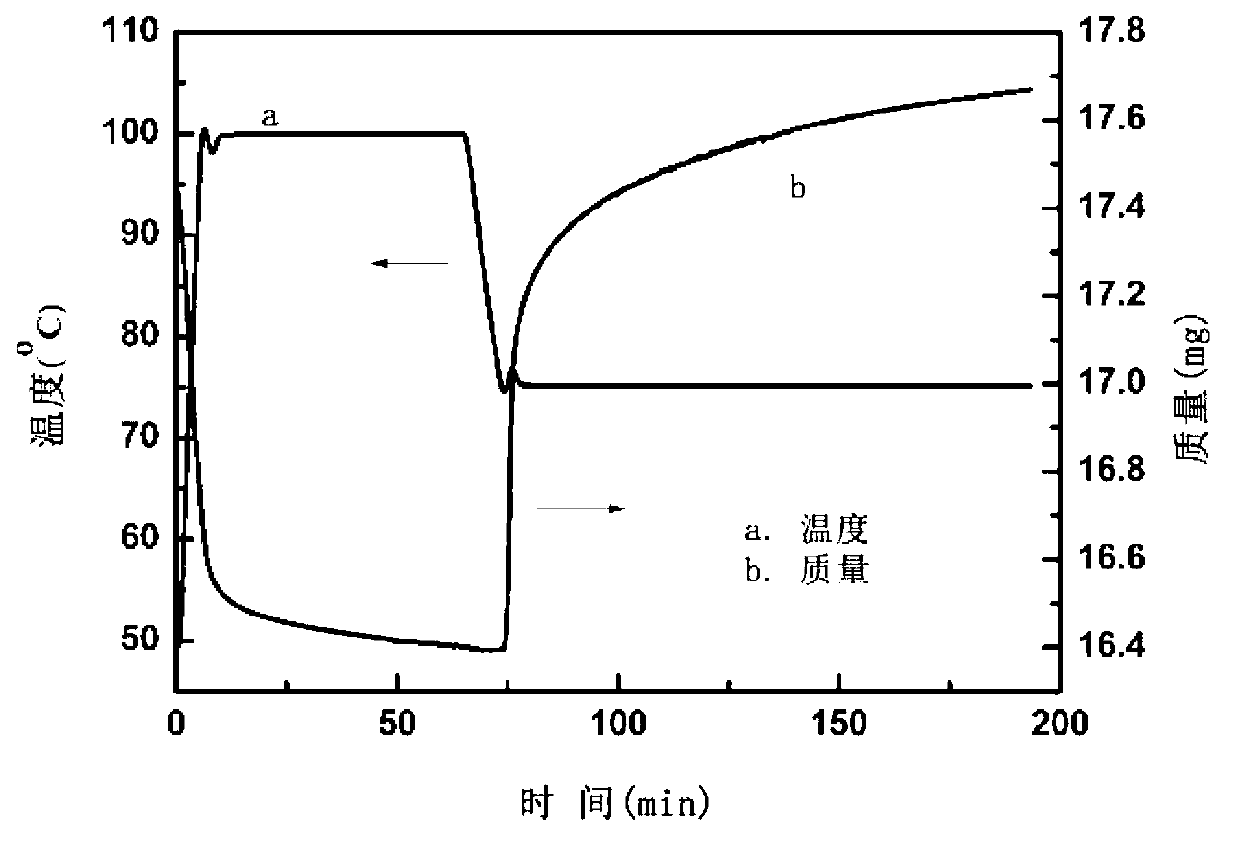

[0033] (1) Acidification modification of montmorillonite: Add 10g of montmorillonite into 100mL sulfuric acid solution (2mol / L), heat to 90°C in a reaction device with condensing reflux, and then stir for 4 hours; The obtained mixed solution was soaked in deionized water, and then filtered; after repeated washing and filtering 3 times, the residual acid solution was removed; then the filtered filter cake was put into an oven, heated to 100°C, and dried for 12 hours to obtain Acidified modified montmorillonite;

[0034] (2) Preparation of polyvinylamide / montmorillonite cage material: Dissolve 3g of polyvinylamide in 40mL of methanol, stir at 25°C for 2 hours, add 3g of acidified modified montmorillonite, continue stirring for 6 hours, At a temperature of 40° C., the methanol solution was removed by evaporation; finally, the obtained sample was placed in a ventilated drying oven, dried at 60° C. for 6 hours, and a cage-shaped carbon dioxide adsorption material was obtained after...

Embodiment 2

[0036] (1) Acidification modification of montmorillonite: Add 15g of montmorillonite into 100mL sulfuric acid solution (2mol / L), heat to 90°C in a reaction device with condensing reflux, and then stir for 4 hours; The resulting mixed solution was soaked in deionized water and then filtered. After repeated washing and filtering 3 times, the residual acid solution was removed; then the filtered filter cake was put into an oven, heated to 100°C, and dried for 12 hours to obtain acidified modified montmorillonite;

[0037] (2) Preparation of polyvinylamide / montmorillonite cage material: Dissolve 3g of polyvinylamide in 40mL of methanol, stir at 25°C for 2 hours, add 3g of acidified modified montmorillonite, continue stirring for 6 hours, At a temperature of 40° C., the methanol solution was removed by evaporation; finally, the obtained sample was placed in a ventilated drying oven, dried at 60° C. for 6 hours, and a cage-shaped carbon dioxide adsorption material was obtained after...

Embodiment 3

[0039](1) Acidification modification of montmorillonite: Add 20g of montmorillonite into 100mL of sulfuric acid solution (2mol / L), heat to 90°C in a reaction device with condensing reflux, and then stir for 4 hours; The obtained mixed solution was soaked in deionized water, and then filtered; after repeated washing and filtering three times, the residual acid solution was removed. Then put the filtered filter cake into an oven, heat to 100°C, and dry for 12 hours to obtain acidified modified montmorillonite;

[0040] (2) Preparation of polyvinylamide / montmorillonite cage material: Dissolve 3g of polyvinylamide in 40mL of methanol, stir at 25°C for 2 hours, add 3g of acidified modified montmorillonite, continue stirring for 6 hours, At a temperature of 40° C., the methanol solution was removed by evaporation; finally, the obtained sample was placed in a ventilated drying oven, dried at 60° C. for 6 hours, and a cage-shaped carbon dioxide adsorption material was obtained after c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com