Method and device for continuous separation of methane, carbon dioxide and hydrogen sulfide from biogas by hydrate method

A carbon dioxide and methane separation technology, applied in the direction of hydrogen sulfide, chemical instruments and methods, hydrocarbons, etc., can solve the problems that cannot meet the requirements, are not conducive to energy saving and emission reduction, and waste resources, so as to improve the gas-liquid contact efficiency and improve Effect of hydration formation rate and recovery improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

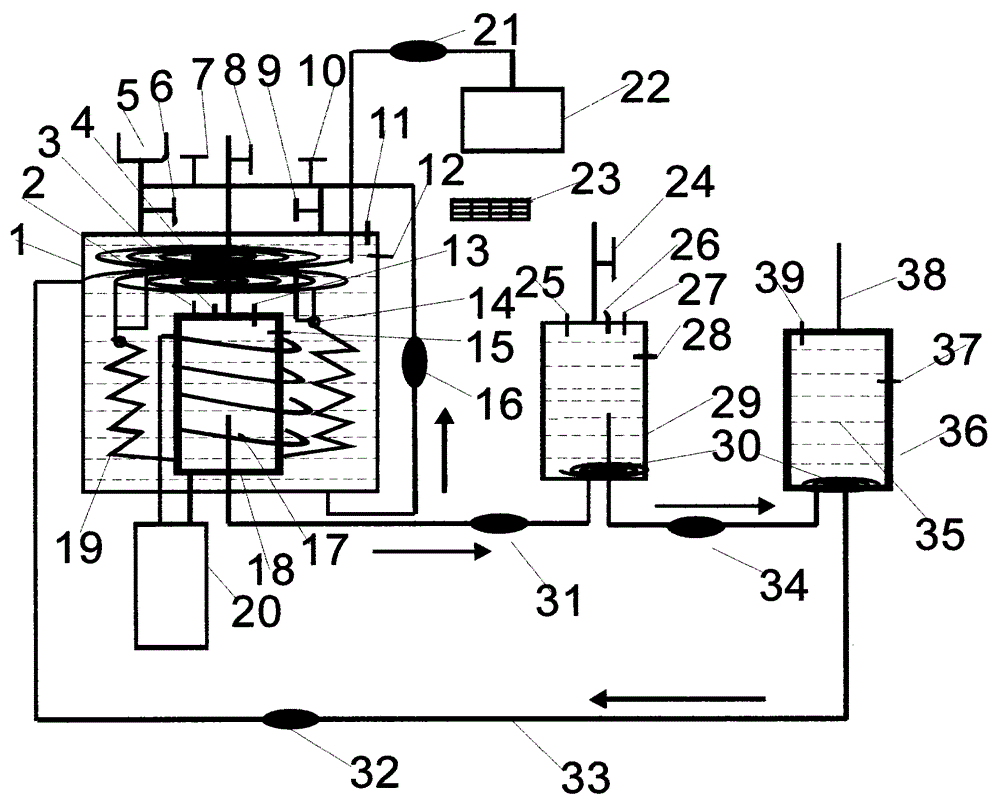

[0028] The hydrate method is a method for continuously separating methane, carbon dioxide, and hydrogen sulfide from biogas. The relationship between the phase equilibrium temperature and pressure of methane gas hydrate is that when the temperature is 273.2K-287.2K, the pressure should be 2.641MPa-11.650MPa, and the carbon dioxide gas The relationship between hydrate phase equilibrium temperature and pressure is when the temperature is 273.7K-283.1K, the pressure should be 1.324MPa-4.502MPa, and the relationship between hydrogen sulfide gas hydrate phase equilibrium temperature and pressure is when the temperature is 272.8K-288.7K, The pressure should be between 0.093MPa and 0.499MPa. The relationship between the phase equilibrium temperature and pressure of the three gas hydrates is very different. Using a suitable hydrate formation accelerator can properly stir and remove the hydrate formation heat in time. , a three-stage gas separation device that can continuously separate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com