Catalyst for olefine polymerizing reaction and its components

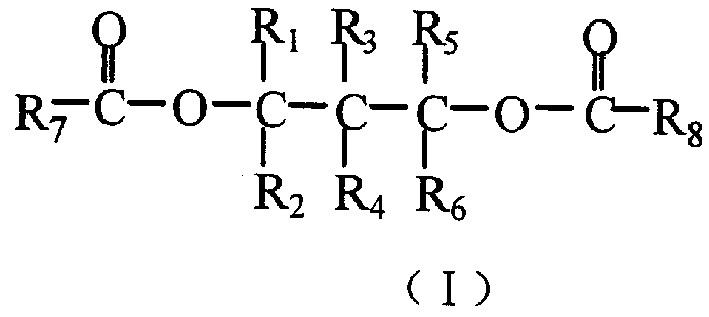

A technology for olefin polymerization and catalyst, which is applied in the field of catalyst components and catalysts for olefin polymerization, and can solve the problems of low catalytic activity of catalysts, unfavorable polymer development, and narrow polymer molecular weight distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 12

[0040] The compound sample is placed in an extractor and extracted with boiling heptane for 6 hours, and the residue is dried to a constant weight. The ratio of the obtained polymer weight (g) to 2 is isotacticity. 5. Determination of infrared spectrum: adopt MAGNA-IR 760 infrared spectrometer of NICOLET company, conventional analysis method. 6. Determination of Polymer Melt Index: According to ASTM D1238-99 Determination of Synthesis Example 12, Synthesis of 4-Pentanediol Dibenzoate

[0041] (1) Preparation of 2,4-pentanediol

[0042]A mixture of 10g of 2,4-pentanedione and 30ml of methanol was added dropwise to a mixed solution of 2.5g of sodium borohydride, 0.1g of sodium hydroxide and 25ml of water at 0-10°C. After the addition, the solvent was removed under reduced pressure and extracted continuously with 40ml of ethyl acetate for 15h. The solvent was removed and column chromatography was performed to obtain 9.4 g of colorless liquid 2,4-pentanediol with a yield of 90%....

Embodiment 2

[0045] 1 H NMR (TMS, CDCl 3 , ppm): δ1.3~1.4 (8H, m, methyl H), 2.0~2.1 (2H, m, methylene H), 5.2~5.3 (2H, m, methine H of ester group), 7.3~8.0 (10H, m, benzene ring H) Example 2 Synthesis of (2S, 4S)-(+)-2,4-pentanediol dibenzoate

[0046] (2S,4S)-(+)-2,4-Pentanediol 3.1g, 30ml tetrahydrofuran and 0.09mol pyridine were added to 0.03mol, 0.075mol benzoyl chloride was added under stirring, and heated to reflux for 4 hours. After cooling, add 20ml of saturated brine, extract with ethyl acetate, anhydrous Na 2 SO 4 Dry and remove solvent. Column chromatography gave 8.9 g of (2S,4S)-(+)-2,4-pentanediol dibenzoate as a colorless liquid, with a yield of 95%.

[0047] 1 H NMR (TMS, CDCl 3 , ppm): δ1.2~1.4 (8H, m, methyl H), 2.0~2.1 (2H, m, methylene H), 5.2~5.3 (2H, m, methine H of ester group), δ7.3~8.0 (10H, m, benzene ring H). Embodiment 3 (2R, 4R)-(+)-2, the synthesis of 4-pentanediol dibenzoate

Embodiment 3

[0048] The method is the same as that of Preparation Example 2, except that (2R,4R)-(+)-2,4-pentanediol is used instead of (2S,4S)-(+)-2,4-pentanediol. 1 HNMR (TMS, CDCl 3 , ppm): δ1.3~1.4 (8H, m, methyl H), 2.0~2.1 (2H, m, methylene H), 5.2~5.3 (2H, m, methine H of ester group), 7.3-8.0 (10H, m, benzene ring H). Embodiment 42, the preparation of 4-pentanediol two (m-chlorobenzoic acid) esters

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com