Light refractory bricks

A refractory brick and lightweight technology, applied in the field of refractory materials, can solve the problems of low thermal conductivity of refractory fiber, service life of lightweight refractory bricks, harmful refractory fibers, etc., and achieve the effect of reducing production costs and increasing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

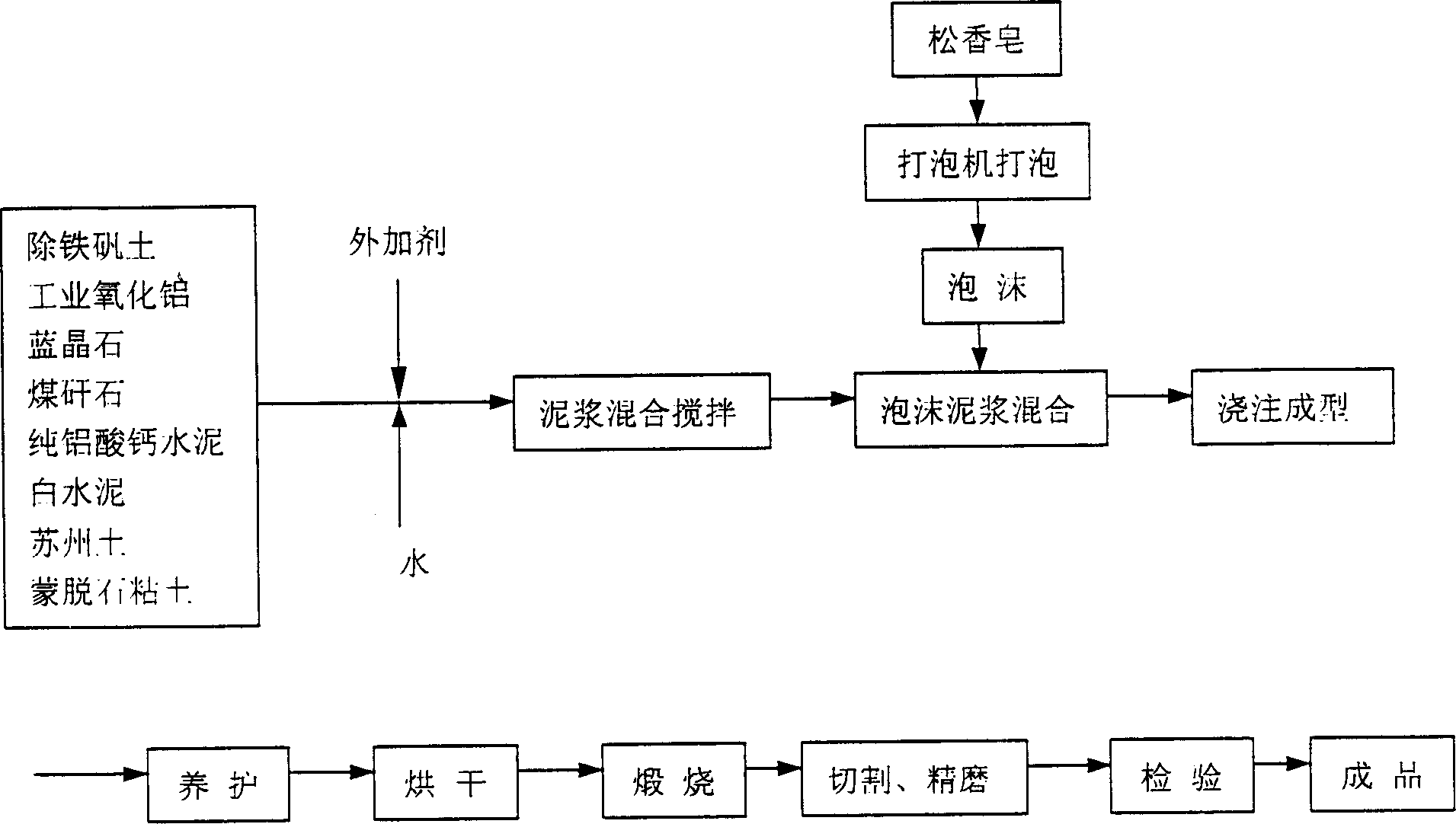

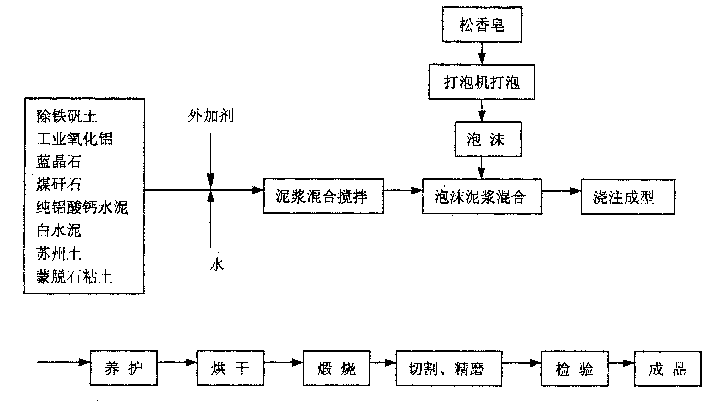

[0028] according to figure 1 As shown, take calcined and ground coal gangue powder 31wt.%, kyanite 30wt.%, pure calcium aluminate cement 10wt.%, bauxite 19wt.%, kaolinite clay 5wt.%, Mongolian Destoned clay 5wt.%, after mixing in a mixer, add sodium citrate aqueous solution accounting for 35% of solids. The concentration of the sodium citrate aqueous solution is 0.5 wt.%. and mix into a homogeneous slurry. Prior to this, prepare rosin soap at a ratio of 0.13 for NaOH / rosin and prepare a foaming solution at a ratio of 1.2 for rosin soap / bone glue. While stirring the mud, put the foaming liquid into the foaming machine for foaming. It is necessary to grasp that when the mud is evenly stirred, the foaming machine can supply a sufficient amount of foam. The slurry is then mixed with the foam. The bulk density of anorthite combined with mullite lightweight refractory bricks is controlled by the amount of foam added. In this embodiment, the bulk density of the product is 0.48g...

Embodiment 2

[0041] according to figure 1 As shown, take kyanite 70wt.%, pure calcium aluminate cement 12wt.%, bauxite 3wt.%, kaolinite clay 4wt.%, montmorillonite clay 6wt.%, mix in the mixer Aqueous sodium citrate solution accounting for 37wt.% of solids was added after homogenization. The concentration of the sodium citrate aqueous solution is 0.5 wt.%. Then the solution is mixed with solid powder to form a uniform slurry. Prior to this, prepare rosin soap at a ratio of 0.13 for NaOH / rosin and prepare a foaming solution at a ratio of 1.2 for rosin soap / bone glue. While stirring the mud, put the foaming liquid into the foaming machine for foaming. It is necessary to grasp that when the mud is evenly stirred, the foaming machine can supply a sufficient amount of foam. The slurry is then mixed with the foam. The bulk density of anorthite combined with mullite lightweight refractory bricks is controlled by the amount of foam added. In this embodiment, the bulk density of the product i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Maximum operating temperature | aaaaa | aaaaa |

| Cold flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com