Three-dimensional porous frame-reinforced fiber aerogel material and preparation method thereof

A three-dimensional porous, fiber-reinforced technology, used in aerogel preparation, chemical instruments and methods, colloid chemistry, etc., can solve problems such as limitations, achieve less raw material limitations, good flexibility and connectivity, good mechanical strength and recovery. The effect of elastic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

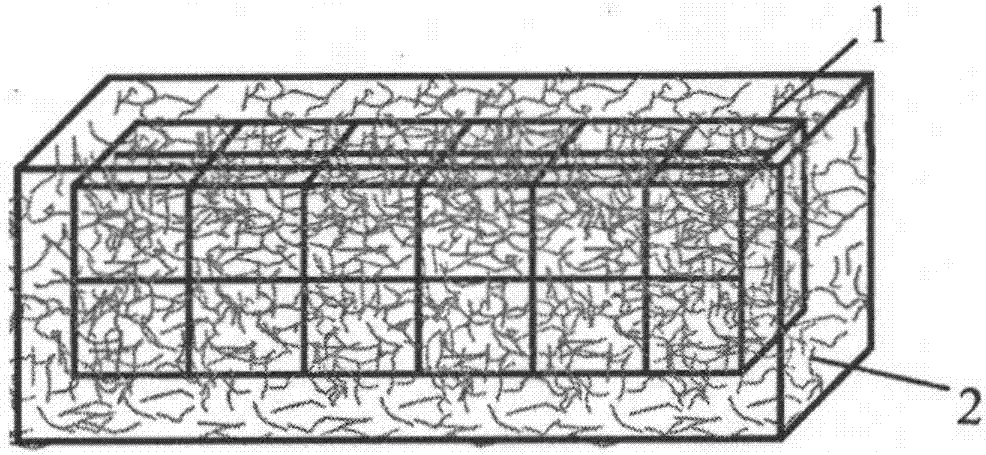

[0037] like figure 1 As shown, a three-dimensional porous frame-reinforced fiber airgel material, which contains a three-dimensional porous frame 1 and fibers 2, the three-dimensional porous frame 1 is used as the main support reinforcement structure, by placing the three-dimensional porous frame in the fiber dispersion slurry, and forming -Solvent drying-curing treatment obtained.

[0038] The specific steps of the preparation method of the described three-dimensional porous frame reinforced fiber airgel material include:

[0039] Step 1: Disperse 10 g of cotton fiber raw materials with an average diameter of 20 μm and an average aspect ratio of 40,000 in 500 g of pure water to prepare a uniform fiber dispersion slurry.

[0040] The second step: using conventional three-dimensional weaving technology to obtain a bulk density of 300mg / cm 3 , the mesh size is 15mm, the three-dimensional porous cotton fabric of 20g rectangular parallelepiped shape that mechanical strength is 1...

Embodiment 2

[0045] like figure 1 As shown, a three-dimensional porous frame-reinforced fiber airgel material, which contains a three-dimensional porous frame 1 and fibers 2, the three-dimensional porous frame 1 is used as the main support reinforcement structure, by placing the three-dimensional porous frame in the fiber dispersion slurry, and forming -Solvent drying-curing treatment obtained.

[0046] The specific steps of the preparation method of the described three-dimensional porous frame reinforced fiber airgel material include:

[0047] Step 1: Disperse 5 g of silk fiber raw materials with an average diameter of 15 μm and an average aspect ratio of 30,000 in 400 g of pure water to prepare a uniform fiber dispersion slurry.

[0048] The second step: using conventional three-dimensional weaving technology to obtain a bulk density of 280mg / cm 3 , the mesh size is 10mm, and the three-dimensional porous silk fabric of 60g cube shape that mechanical strength is 15kPa is immersed in 405...

Embodiment 3

[0052] like figure 1 As shown, a three-dimensional porous frame-reinforced fiber airgel material, which contains a three-dimensional porous frame 1 and fibers 2, the three-dimensional porous frame 1 is used as the main support reinforcement structure, by placing the three-dimensional porous frame in the fiber dispersion slurry, and forming -Solvent drying-curing treatment obtained.

[0053] The specific steps of the preparation method of the described three-dimensional porous frame reinforced fiber airgel material include:

[0054] Step 1: Disperse 3.6 g of polyimide fiber raw materials with an average diameter of 10 μm and an average aspect ratio of 50,000 in a mixed solvent of 200 g of water and 200 g of isopropanol to prepare a uniform fiber dispersion slurry.

[0055] The second step: using conventional foam molding technology to prepare a bulk density of 60mg / cm 3 , with a mesh size of 3mm and a mechanical strength of 25kPa, 20g of cube-shaped three-dimensional porous p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com