A Vibration Feed Movement Realization Device for Electrolytic Machining

A technology of feeding motion and machining vibration, applied in electric machining equipment, electrochemical machining equipment, accessories, etc., can solve the problems of low efficiency of electrolytic machining and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

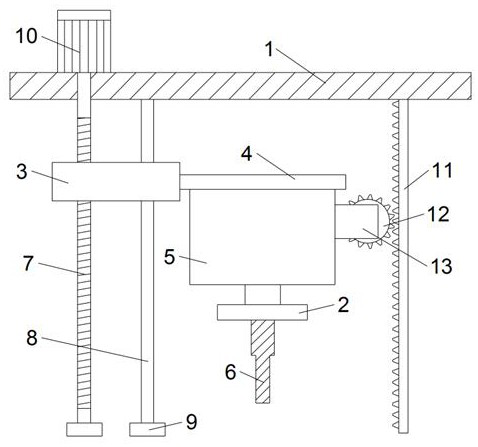

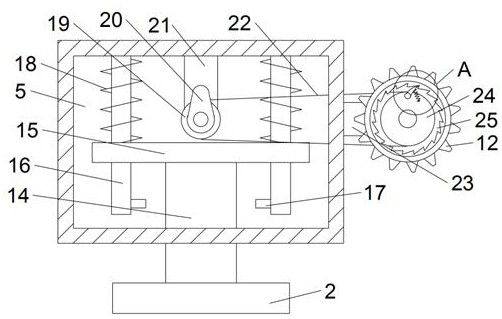

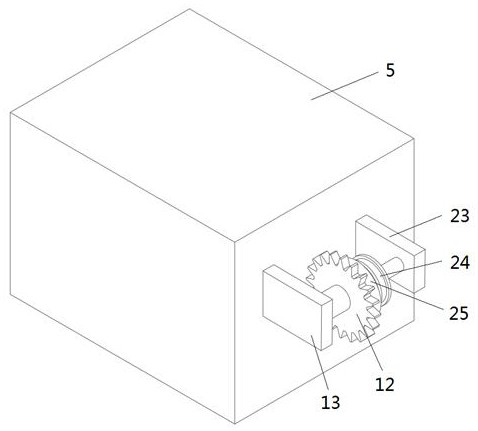

[0024] Refer to attached Figure 1-4 , this embodiment provides a vibration feed movement realization device for electrolytic machining, which includes a fixed plate 1 and a mounting block 2 for installing a cathode tool 6, a slide block 3 is provided slidingly below the fixed plate 1, and the The slider 3 is connected with the feed mechanism which is used to drive the slider 3 to move up and down and has a self-locking function. The slider 3 is provided with a vibration chamber 5, and a movable plate is installed in the vibration chamber 5. 15. The mounting block 2 is arranged at the bottom of the movable plate 15; the movable plate 15 is connected with the vibrating assembly for driving the movable plate 15 to vibrate, and the vibration chamber 5 and the fixed plate 1 are provided with Transmission assembly; when the slider 3 descends, the transmission assembly drives the vibrating assembly to vibrate.

[0025] Specifically, the connecting plate 4 is fixed on the slider 3, ...

Embodiment 2

[0031] Refer to attached Figure 5 , this embodiment is improved on the basis of Embodiment 1, specifically, the bottom of the installation block 2 is provided with a clamping assembly for fixing the cathode tool 6 . Wherein, the clamping assembly includes two sets of positioning blocks 28, the positioning blocks 28 are fixed on the bottom of the installation block 2, and the clamping screws 29 for clamping the cathode tool 6 are threaded on the positioning blocks 28 . When the cathode tool 6 needs to be installed, the cathode tool 6 is first placed between two sets of positioning blocks 28, and then the clamping screws 29 on the two sets of positioning blocks 28 are tightened so that the clamping screw 29 is offset against the cathode tool 6, The fixed installation of the cathode tool 6 can be completed.

[0032] In summary, the embodiment of the present invention arranges the mounting block 2 at the bottom of the movable plate 15, slides the movable plate 15 in the vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com