Device for electrochemical machining of template

A template and electrolyte technology, applied in electric machining equipment, electrochemical machining equipment, supply of machining working medium, etc., can solve the problem that the influence of mass transfer rate is no longer significant, it is difficult to eliminate, and hinders the continuous progress of electrolytic machining, etc. Achieve the effect of improving electrolytic processing efficiency, increasing electrolyte flow rate, and enhancing mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

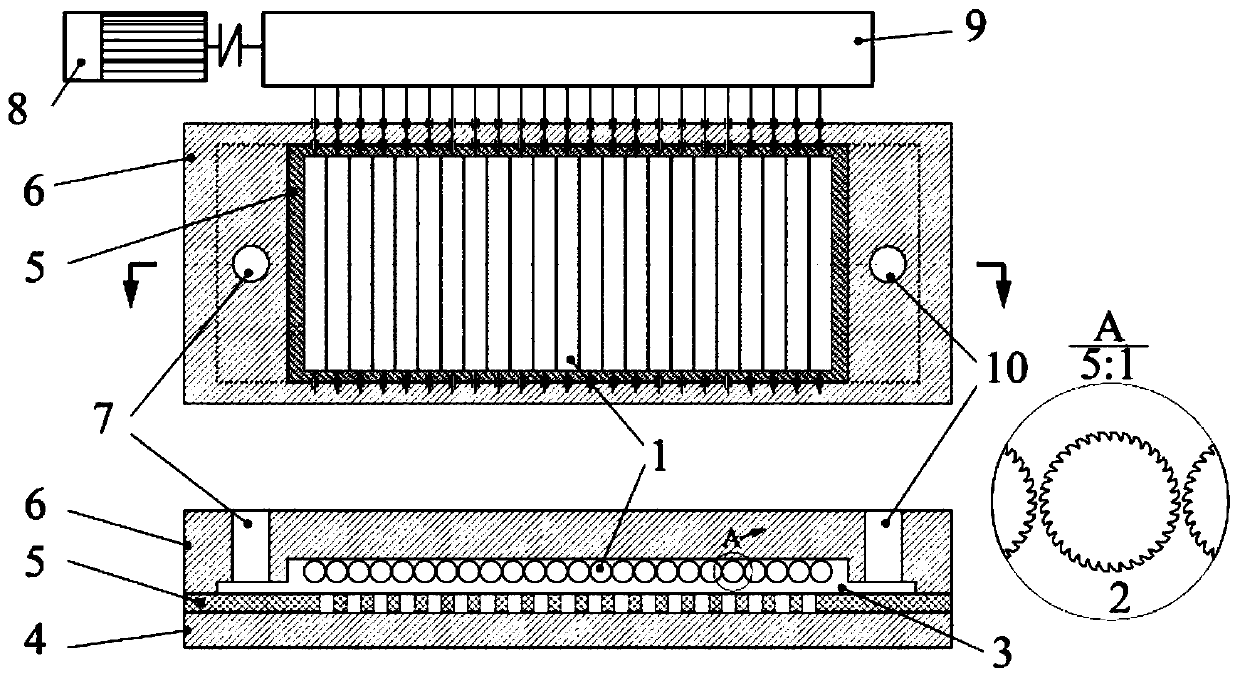

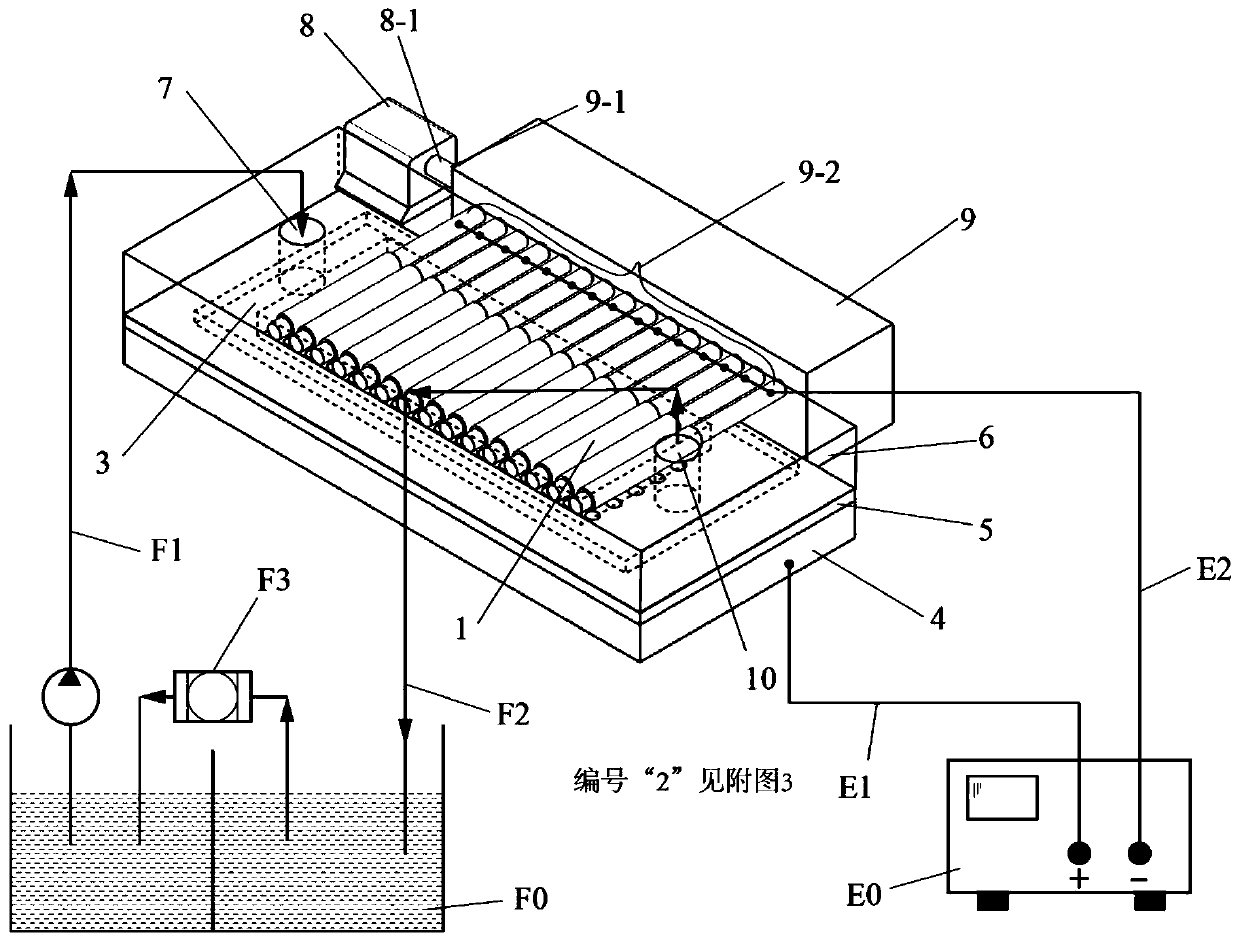

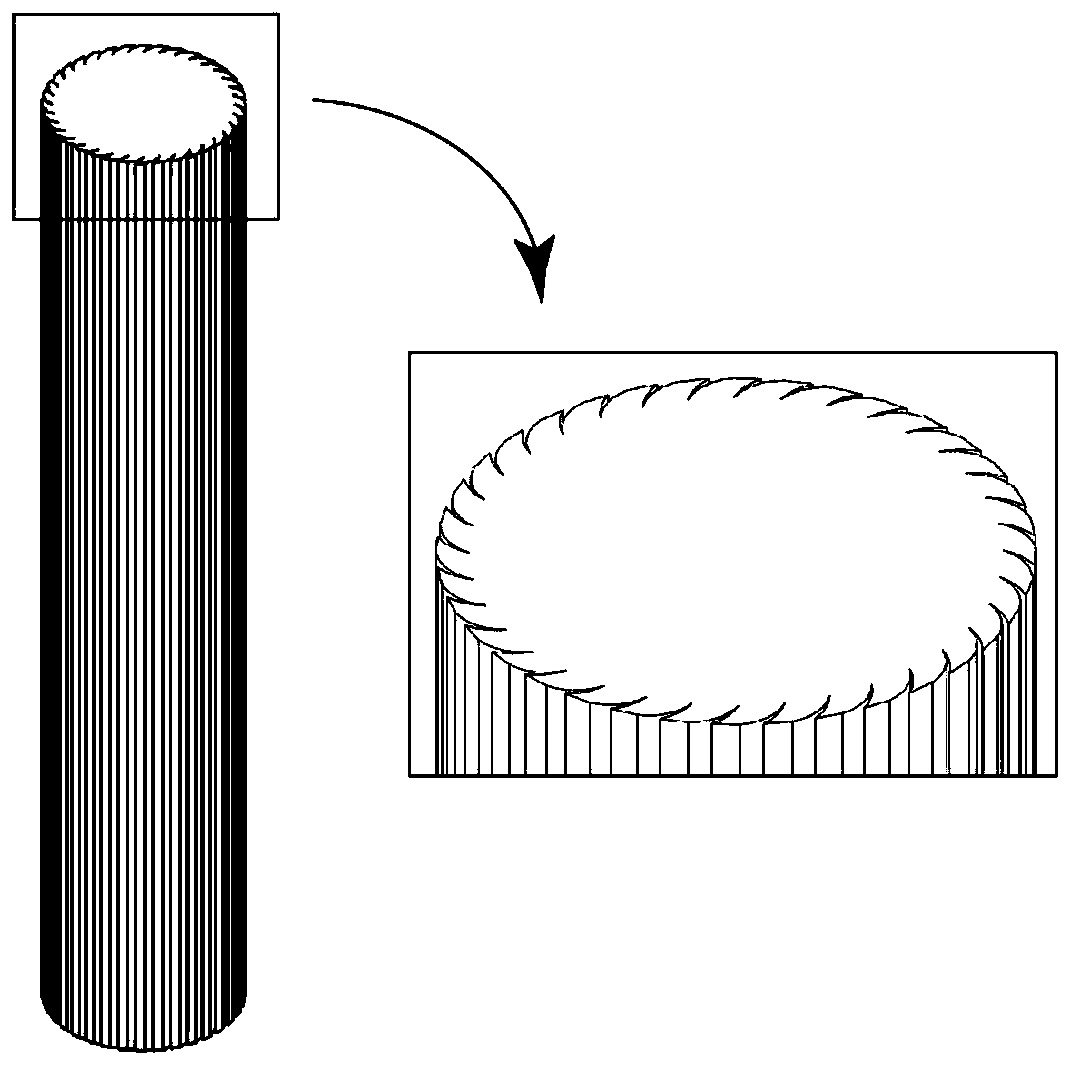

[0019] Such as figure 1 and image 3 A device for template electrolytic machining provided in this embodiment includes a clamp 6 and a template 5, an electrolyte flow channel cavity is formed between the clamp 6 and the template 5, and a set of electrodes connected to the negative pole of the power supply is arranged in the electrolyte flow channel cavity. The outer wall of each metal column 1 is provided with a circle of convex teeth. The protruding teeth on the metal post 1 are all inclined in the same direction. The distance between the edges of the metal pillars 1 is 0.2mm. If the distance is too small, it will cause difficulties in manufacturing the device itself. If the distance is too large, it will affect the continuity of the electric field. The distance between the lower edge of the metal pillars 1 and the template is 0.3mm. The smaller the distance between the templates, the better the machining efficiency and precision. However, according to the results of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com